Polymer solar cell with reverse structure and preparation method thereof

A technology of solar cells and polymers, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of ITO substrate damage, no innovation, low conductivity, etc., achieve good electron and hole transport capabilities, and highlight the essence Sexual characteristics, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

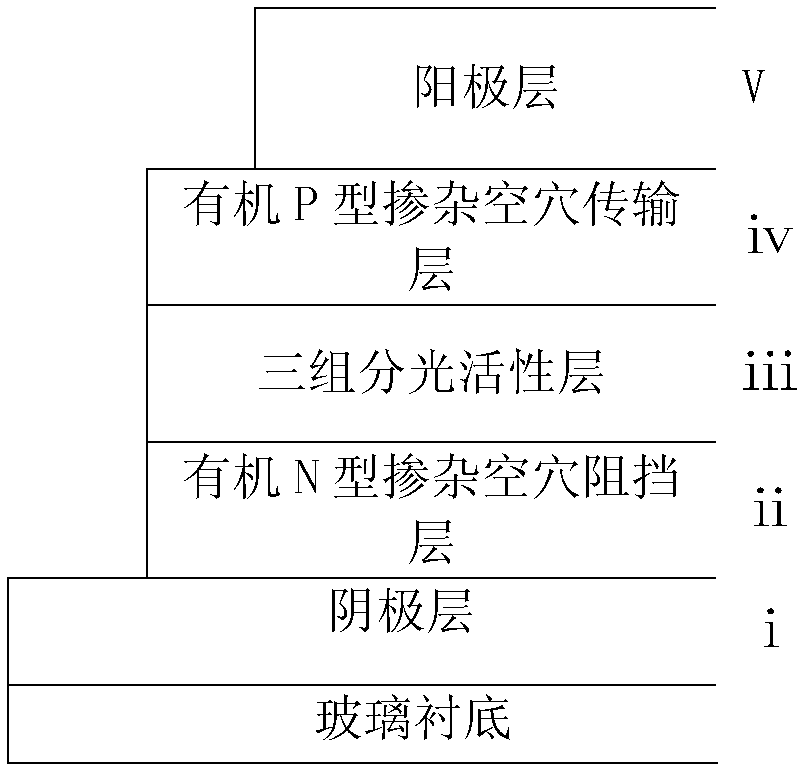

[0042] The preparation structure is NTCDA with a thickness of 100nm / NTCDA with a thickness of 10nm: LCV=1:0.01 / P3HT with a thickness of 80nm:PC 61 BM:BCP=12:10:0.1 / NPB:WO with a thickness of 10nm 3 = 1:0.05 / Ag-thick reverse structure polymer solar cell with a thickness of 100 nm.

[0043] The polymer solar cell of this inversion structure is made of the ITO cathode layer of one layer thickness 100nm on the glass substrate, the NTCDA of the thickness 10nm that is deposited on the ITO cathode layer: LCV thin film organic N-type doped hole blocking layer 1. A layer of P3HT:PC with a thickness of 80nm deposited on the NTCDA:LCV thin film organic N-type doped hole blocking layer 61 BM:BCP film three-component photoactive layer, one layer deposited on P3HT:PC 61 10nm-thick NPB:WO on three-component photoactive layer of BM:BCP film 3 Thin-film organic P-type doped hole-transport layer and a layer deposited on NPB:WO 3 A polymer solar cell with an inversion structure composed of a...

Embodiment 2

[0067] The preparation structure is NTCDA with a thickness of 100nm / NTCDA with a thickness of 10nm: LCV=1:0.05 / PCPDTBT with a thickness of 120nm:PC 71 BM:Bphen=12:15:0.1 / NPB with a thickness of 25nm:WO 3 =1:0.2 / Ag inversion structure polymer solar cell with a thickness of 100 nm.

[0068] The polymer solar cell of this inversion structure is made of the ITO cathode layer of one layer thickness 100nm on the glass substrate, the NTCDA of the thickness 10nm that is deposited on the ITO cathode layer: LCV thin film organic N-type doped hole blocking layer 1. One layer of PCPDTBT:PC with a thickness of 120nm deposited on the NTCDA:LCV thin film organic N-type doped hole blocking layer 71 BM:Bphen film three-component photoactive layer, one layer deposited on PCPDTBT:PC 71 25nm-thick NPB:WO on three-component photoactive layer of BM:Bphen film 3 Thin-film organic P-type doped hole-transport layer and a layer deposited on NPB:WO 3 A polymer solar cell with an inversion structure ...

Embodiment 3

[0083] The preparation structure is NTCDA with a thickness of 20nm / NTCDA with a thickness of 10nm:LCV=1:1 / P3HT with a thickness of 80nm:PC 61 BM:BCP=12:10:0.01 / NPB:WO with a thickness of 50nm 3 = 1:0.5 / Ag inversion structure polymer solar cell with a thickness of 100 nm.

[0084] The polymer solar cell of this reverse structure is by the Ag cathode layer of one deck thickness 20nm on the glass substrate, the NTCDA of thickness 10nm that one deck is deposited on the Ag cathode layer: LCV thin film organic N-type doped hole blocking layer 1. A layer of P3HT:PC with a thickness of 80nm deposited on the NTCDA:LCV thin film organic N-type doped hole blocking layer 61 BM:BCP film three-component photoactive layer, one layer deposited on P3HT:PC 61 50nm-thick NPB:WO on three-component photoactive layer of BM:BCP film 3 Thin-film organic P-type doped hole-transport layer and a layer deposited on NPB:WO 3 A polymer solar cell with an inversion structure composed of an Ag anode lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com