A kind of preparation method of solar battery sheet with color pattern

A technology of solar cells and color patterns, applied in the manufacture of circuits, electrical components, final products, etc., can solve the problem of single color components and achieve high flexibility, easy removal, good controllability and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

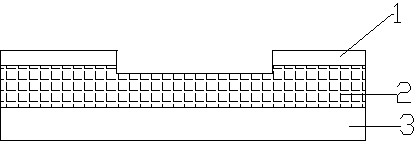

[0016] The silicon wafer 3 enters the process of making the mask 1 and chemical etching after the processes of texturing, diffusion, edge etching, phosphosilicate glass removal, and anti-reflection coating 2 processes.

[0017] This example mask 1 adopts paraffin, and chemical reagent adopts the phosphoric acid solution that mass ratio is 10%, and specific implementation process is as follows:

[0018] A. The surface of the silicon wafer 3 coated with the antireflection film 2 is printed on the surface of the silicon wafer 3 with the mask 1 by spray printing;

[0019] B. Put the silicon wafer 3 with the mask 1 into a phosphoric acid solution with a concentration of 10%, and chemically etch it for 3 minutes;

[0020] C. Wash the silicon wafer 3 corroded by phosphoric acid in deionized water for 1 minute, and then put it in dewaxing water or trichlorethylene solution to remove the paraffin mask 1;

[0021] D. Put the silicon wafer 3 from which the mask 1 has been removed into d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com