Non-woven fabric with double-faced malposed embossing

A non-woven fabric and embossing technology, which is applied in the field of non-woven fabrics with double-sided dislocation embossing, can solve the problems of monotonous wiping friction and poor wiping effect, and achieve increased wiping friction, reduced thickness, and beautiful appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

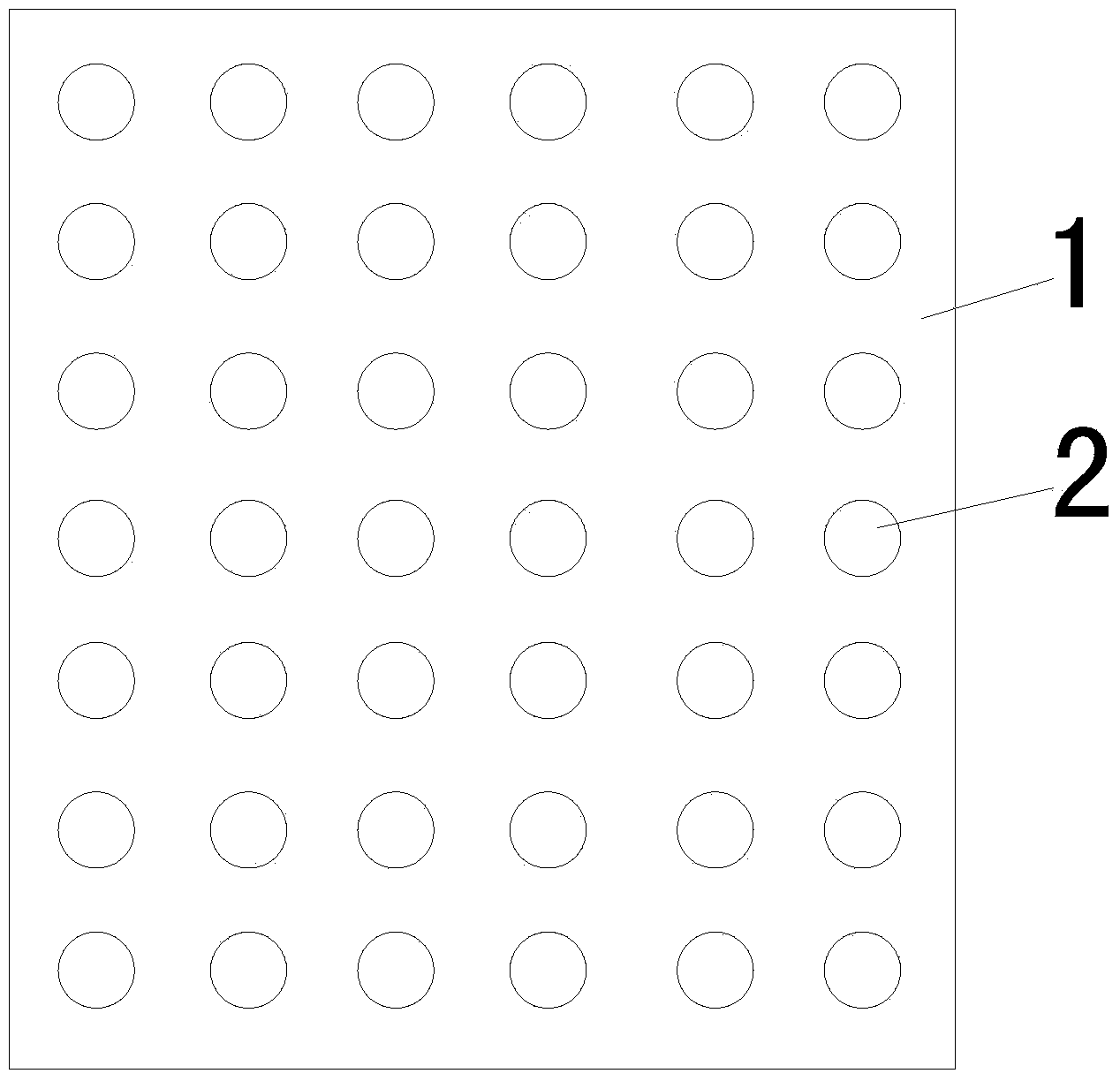

[0014] attached figure 1 , 2 It is a non-woven fabric with double-sided dislocation embossing according to the present invention, which includes a non-woven fabric body 1; a plurality of regularly arranged grooves 2 are respectively provided on the two sides of the non-woven fabric body 1 The plurality of grooves arranged on each side of the non-woven body 1 form embossing respectively; Mutually misaligned; in this embodiment, the groove 2 is circular.

[0015] Certainly, the groove 2 may also be arranged in a petal shape.

[0016] Due to the application of the above-mentioned technical solution, the present invention has the following advantages compared with the prior art:

[0017] According to the non-woven fabric with double-sided offset embossing according to the present invention, a plurality of regularly arranged grooves ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com