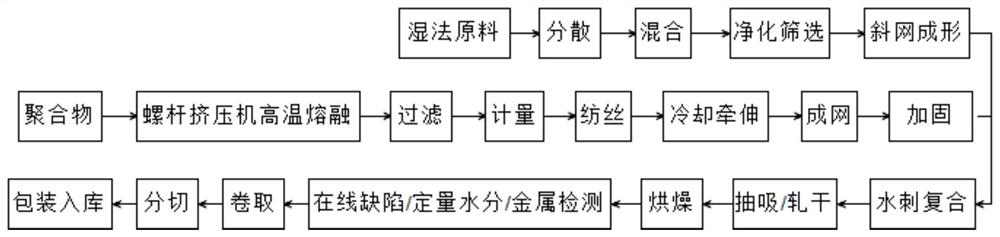

Inclined net forming online spun-bonded spunlace composite non-woven fabric and preparation method thereof

A technology of non-woven fabrics and inclined nets, which is applied in the field of spunlace composite non-woven fabrics and its preparation, and can solve problems such as lack of strength, waste of spunlace energy consumption, and product hardening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

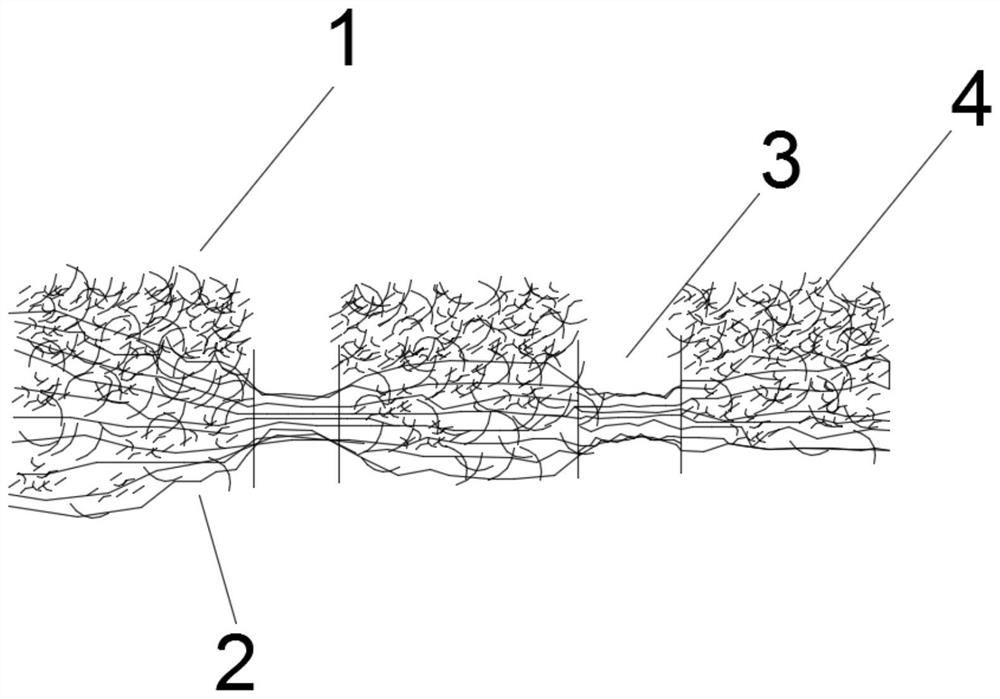

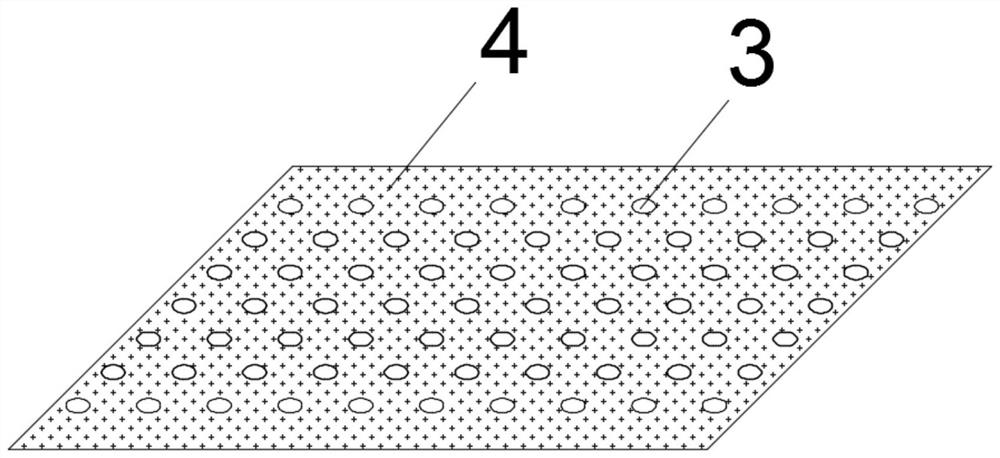

[0046] Example 1: Reference Figure 1 to Figure 6 , a kind of spunlace composite non-woven fabric formed by inclined net forming on-line spunbond, comprising a first fiber layer 1 and a second fiber layer 2, and is formed by laminating the first fiber layer 1 and the second fiber layer 2, the first The fiber layer 1 is a wet-process inclined wire forming fiber web layer, the second fiber layer 2 is a spunbonded fiber web layer, the first fiber layer 1 is made of wood pulp fibers with a mass percentage of 100%, and the second fiber layer 2 is made of wood pulp fibers with a mass percentage of Made of 100% synthetic fibers, the second fiber layer 2 is distributed with a thermally bonded consolidated area and a non-consolidated fluffy area, and the fibers of the first fiber layer 1 are inserted into the non-consolidated area at the corresponding position of the second fiber layer 2. In the fluffy area and intertwined with the second layer of fibers, the surface of the first fiber...

Embodiment 2

[0062] Example 2: Reference Figure 1 to Figure 6, a kind of spunlace composite non-woven fabric formed by inclined net forming on-line spunbond, comprising a first fiber layer 1 and a second fiber layer 2, and is formed by laminating the first fiber layer 1 and the second fiber layer 2, the first The fiber layer 1 is a wet-process inclined wire forming fiber web layer, the second fiber layer 2 is a spunbonded fiber web layer, and the first fiber layer 1 is composed of 20% by mass of wood pulp fibers and 80% by mass of cellulose fibers The second fiber layer 2 is made of synthetic fibers with a mass percentage of 100%. The second fiber layer 2 is distributed with a thermally bonded consolidated area and a non-consolidated fluffy area. The fibers of the first fiber layer 1 are inserted into the second fiber layer. In the non-consolidated fluffy region at the corresponding position of the second fiber layer 2 and intertwined with the second layer of fibers, the surface of the fi...

Embodiment 3

[0079] Example 3: Reference Figure 1 to Figure 6 , a kind of spunlace composite non-woven fabric formed by inclined net forming on-line spunbond, comprising a first fiber layer 1 and a second fiber layer 2, and is formed by laminating the first fiber layer 1 and the second fiber layer 2, the first The fiber layer 1 is a wet-process inclined wire forming fiber web layer, the second fiber layer 2 is a spunbonded fiber web layer, and the first fiber layer 1 is composed of 50% by mass of wood pulp fibers and 50% by mass of cellulose fibers The second fiber layer 2 is made of synthetic fibers with a mass percentage of 100%. The second fiber layer 2 is distributed with a thermally bonded consolidated area and a non-consolidated fluffy area. The fibers of the first fiber layer 1 are inserted into the second fiber layer. In the non-consolidated fluffy region at the corresponding position of the second fiber layer 2 and intertwined with the second layer of fibers, the surface of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com