Fly ash aluminum extraction residue cement

A technology for extracting aluminum from fly ash and extracting aluminum residue is applied in the field of building materials, which can solve the problems of occupying land, secondary environmental pollution, affecting the economic benefits of extracting alumina from fly ash, etc. The effect of alleviating the shortage of mineral resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

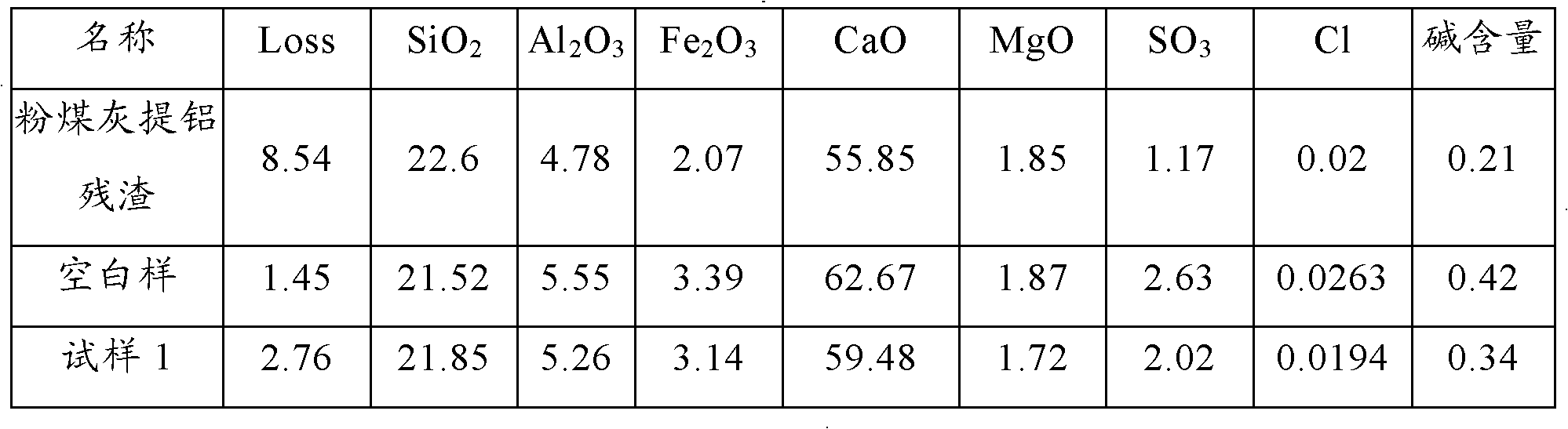

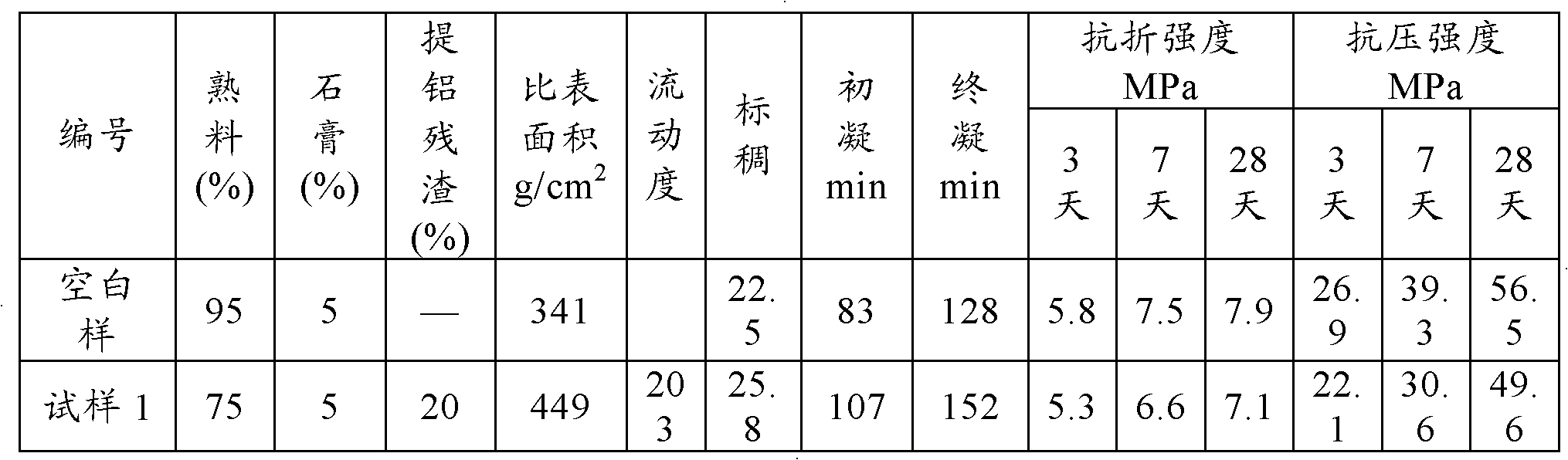

Embodiment 1

[0032] Calcium-silicate slag obtained by extracting alumina by soda-lime sintering of fly ash is processed through the following dealkalization process. The steps of the dealkalization process are as follows: (1) adding water to the aluminum extraction residue and stirring to obtain an aluminum extraction residue slurry; (2) slowly adding calcium carbide slag to the aluminum extraction residue slurry under stirring to carry out dealkalization; (3 ) filtering and washing the aluminum extraction residue slurry after the dealkalization reaction. The alkali content of fly ash extracting aluminum residue is below 0.6%, which has a good application prospect in the cement building material industry from the perspective of physical and chemical properties. Then the above-mentioned fly ash extracting aluminum residue is dried, and the mass percentage of water in the fly ash extracting aluminum residue after drying is 2%, and the drying steps are as follows: the fly ash extracting alumi...

Embodiment 2

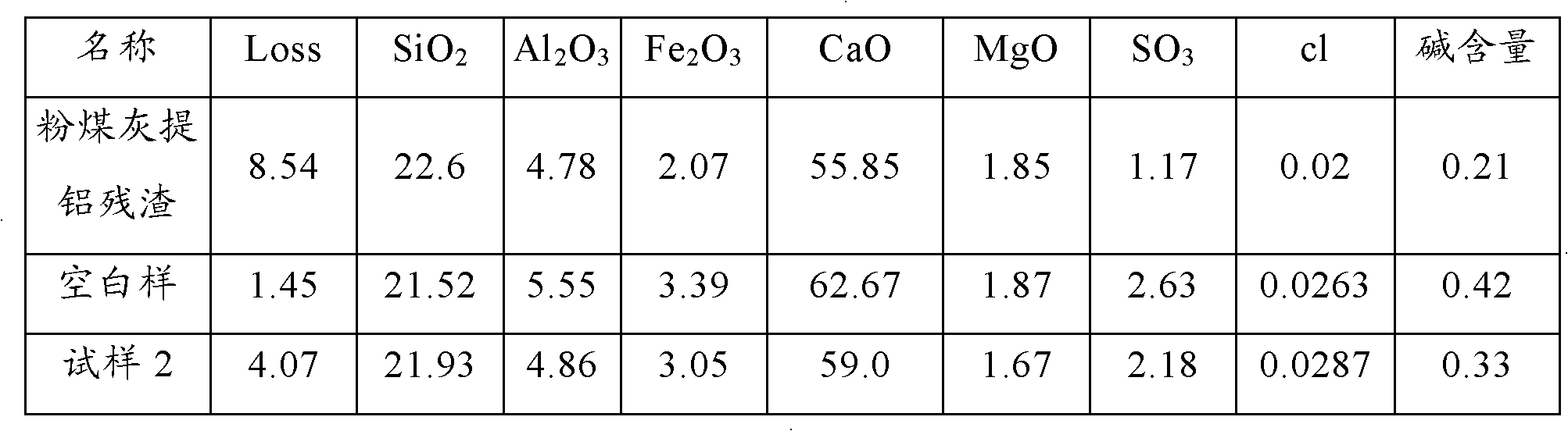

[0042] Different from Embodiment 1, the raw materials used in this embodiment include: fly ash aluminum extraction residue: 40 parts by weight, cement clinker (P.O52.5 cement clinker): 55 parts by weight, gypsum (industrial gypsum): 5 parts by weight were mixed, and then the prepared cement mixture was ground through a cement mill (ball mill) for 1 hour to obtain the fly ash aluminum extraction residue cement sample 2. After fine grinding, the particle size reached GB-T 21372-2008 silicate The particle size requirements in cement clinker, fly ash aluminum extraction residue cement sample 2 meets the performance requirements of ordinary Portland cement with a grade of 32.5. Its specific composition analysis results are shown in Table 3, and the physical performance indicators are shown in Table 4. Same as sample 1, fly ash aluminum extraction residue cement sample 2 has high early strength, and the strength increase is relatively stable without too much fluctuation. The initial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com