Wax deposition preventing organic paint and preparation method of organic coating containing it

An organic coating and organic coating technology, which is applied in the preparation of organic coatings and the field of anti-wax organic coatings, can solve the problems of weak surface hydrophilicity, high cost, and expensive polyvinylidene fluoride, and achieve enhanced oil delivery and oil storage capacity, improve oil output capacity, and shorten curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

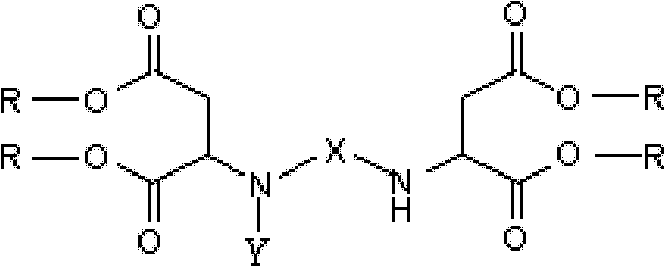

[0059] At the same time, in a typical embodiment of the present invention, there is also provided a method for preparing an anti-waxing organic coating, which includes the following steps: preparing the above-mentioned organosilicon polyaspartic acid having the structure in the structural formula (1) Ester; The prepared silicone polyaspartate and isocyanate are mixed and stirred uniformly to form the anti-waxing organic coating of the present invention, and the anti-waxing organic coating is uniformly coated to form an organic coating. The organic coating provided by the invention does not sag, can be leveled, and has the effects of high surface smoothness and flatness. At the same time, it has low surface energy, good stain resistance, high temperature resistance, and has a good effect of preventing wax formation and reducing drag.

[0060] In the preparation method of the above-mentioned anti-waxing organic coating, the preparation of silicone polyaspartate includes the followi...

Embodiment 1

[0063] Example 1 (The molar ratio of the linear amino-terminated polysiloxane to the side chain amino-containing polysiloxane is 9:1)

[0064] Raw materials: 1728g linear amino-terminated polysiloxane; 15452g side-chain amino-terminated polysiloxane; 3612g diethyl maleate; 2334g isocyanate curing agent isophorone diisocyanate with a functionality of 2; flow Ping agent 447g.

[0065] Among them, in the linear amino-terminated polysiloxane, R′ is methyl; R″ is methyl; n is 1; the chemical structure is as follows:

[0066]

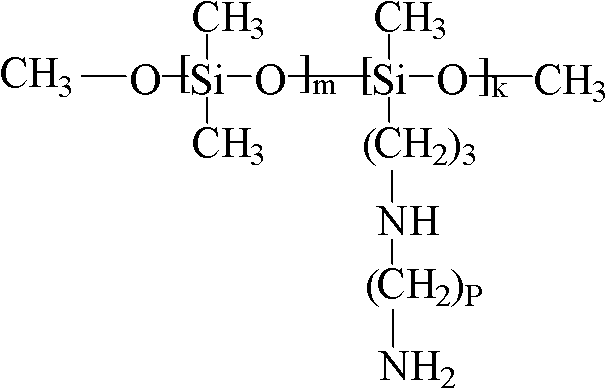

[0067] In the side chain amino-containing polysiloxane, m is 200.; k is 3; P is 5; the chemical structure is as follows:

[0068]

[0069] Preparation:

[0070] Preparation of organosilicon polyaspartate: Put straight-chain amino-terminated polysiloxane and side-chain amino-containing polysiloxane into a three-neck reactor with a reflux device containing 6653g xylene. Slowly stir the system uniformly and heat up to 60°C, add diethyl maleate dropwise at a constant sp...

Embodiment 2

[0072] Example 2 (The molar ratio of the linear amino-terminated polysiloxane to the side chain amino-containing polysiloxane is 1:9)

[0073] Raw materials: linear amino-terminated polysiloxane 14918g; side chain amino-containing polysiloxane 2394g, diethyl maleate 1892g; functionality 3 isocyanate curing agent (Bayer's DESMODURN3300) 3179g; leveling Agent 391g.

[0074] Among them, in the linear amino-terminated polysiloxane, R′ is methyl; R″ is methyl; n is 200; the chemical structure is as follows:

[0075]

[0076] In the side chain amino-containing polysiloxane, m is 1; k is 1; P is 1. The chemical structure is as follows:

[0077]

[0078] Preparation of organosilicon polyaspartate: Put straight-chain amino-terminated polysiloxane and side chain amino-containing polysiloxane into a three-neck reactor with a reflux device containing 5464 g of xylene. Slowly stir the system uniformly and heat up to 60°C, add diethyl maleate dropwise, drip in 1.5 hours, keep at 60°C for 4 hours, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com