A kind of preparation method of SIC particle reinforced Cu-based gradient composite material

A composite material and particle reinforcement technology, applied in the field of composite materials, can solve the problems of thin gradient composite materials, low production efficiency, wear resistance limitation, etc., to achieve the effect of ensuring thermal stress relaxation function and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, SiC particle reinforced Cu-based gradient composite material preparation method:

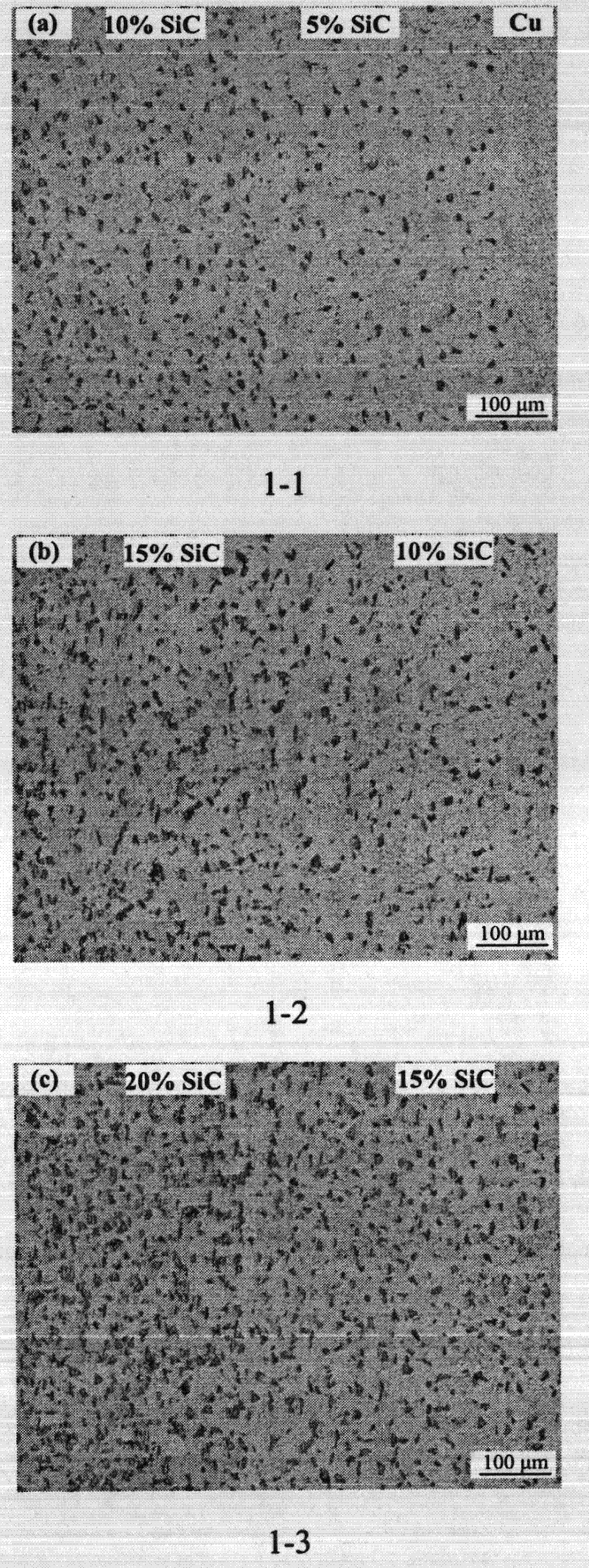

[0029] The matrix material of the gradient composite material is ordinary electrolytic copper powder, the purity is greater than 99.8%, and the average particle size is 200 mesh; the reinforcement material of the gradient composite material is SiC particles, and the average particle size is 20 μm. The composition distribution function in the form of power function is selected, and the step distribution is used to approximate the linear analysis method. This distribution form has strong adaptability and is convenient for mathematical processing and application. Six kinds of homogeneous copper-based composite powders with different SiC particle contents were prepared first, and then gradient composites were prepared by two-way pressing with a floating die. The volume fraction of SiC particles in each layer of the gradient composite material is from the 25% SiC+75% Cu composite...

Embodiment 2

[0034] Example 2, SiC particle reinforced Cu-based gradient composite material performance

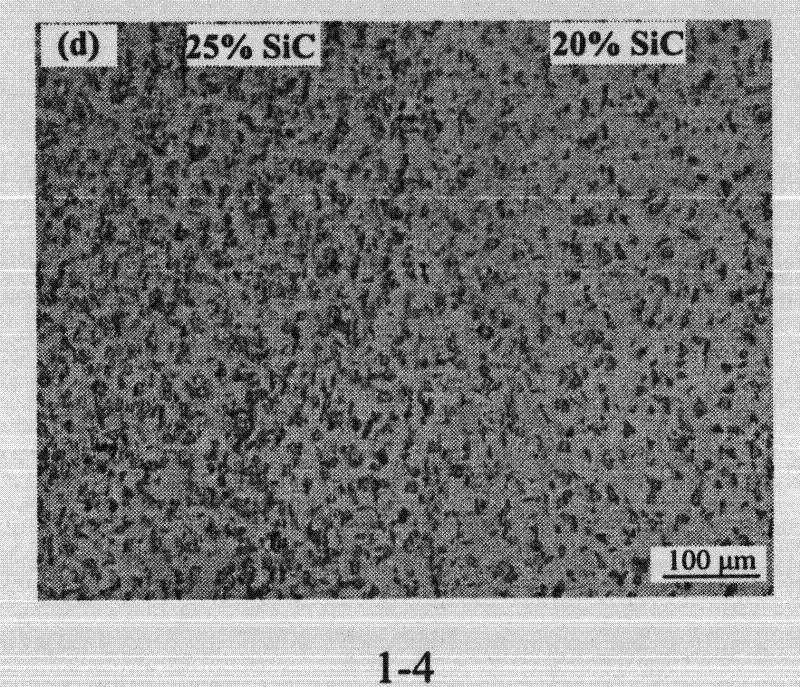

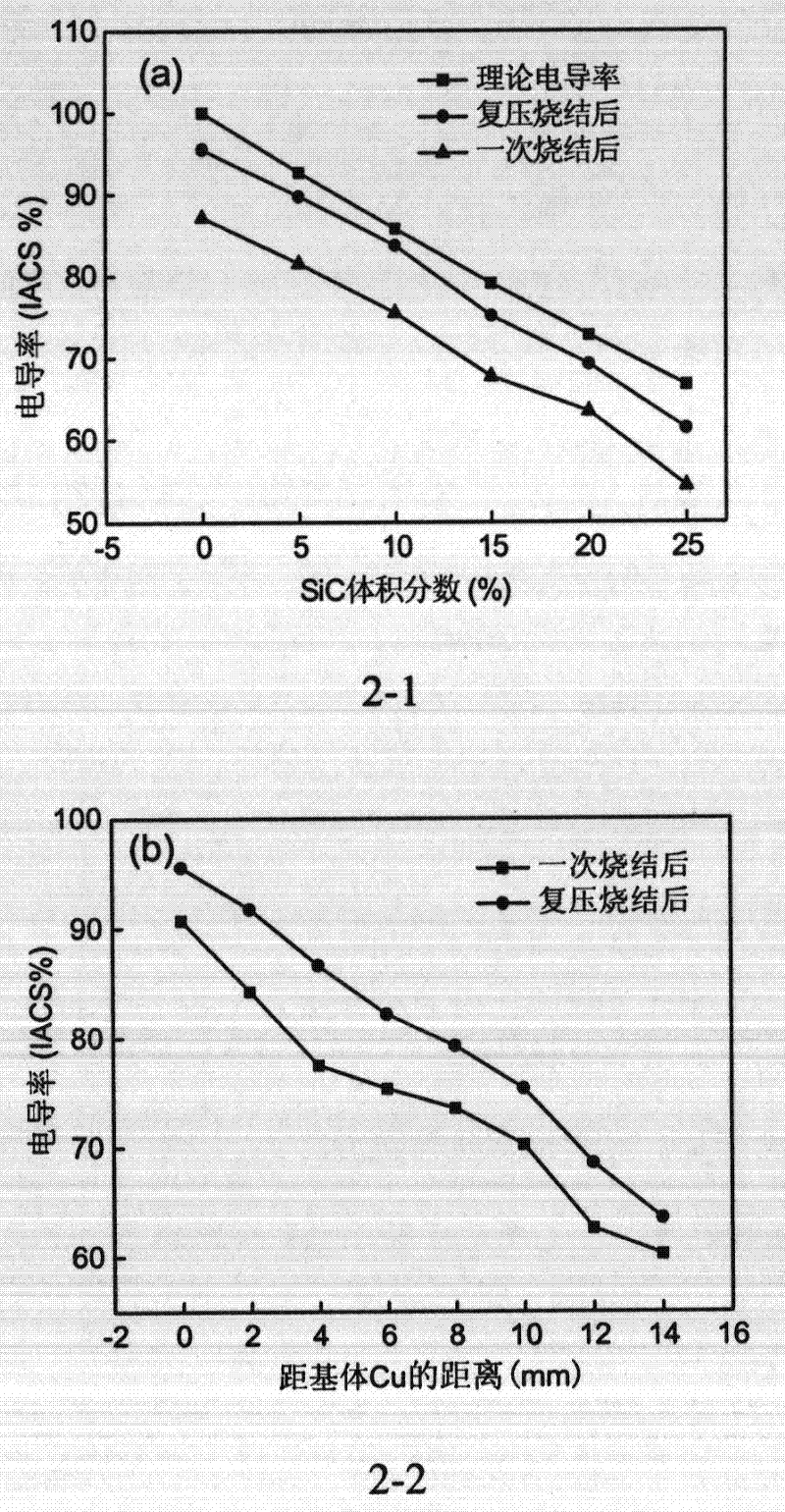

[0035] 1. Conductivity of Cu-based gradient composites reinforced by SiC particles

[0036] The electrical conductivity of composite materials is greatly affected by the density of the material. The 7501 eddy current conductivity meter was used to test the conductivity of the composite material after one-time sintering and re-pressure sintering, and compared with the theoretically calculated conductivity. The test results are as follows: figure 2 shown. Among them, 2-1 is the conductivity curve of SiC content and composite material, and 2-2 is the conductivity curve of distance from 100% Cu in the gradient layer and the conductivity curve of composite material. All values in the figure are according to the international annealed copper standard LACS (International Annealed Copper Standard) said. analyze diagram 2-1 It can be seen from the curve that the electrical conductivity ...

Embodiment 3

[0049] Example 3, SiC particle reinforced Cu-based gradient composite material application field

[0050] SiC particle reinforced Cu-based gradient composite material has good electrical conductivity, excellent heat resistance and oxidation resistance, and excellent wear resistance. There are broad prospects for development in terms of pantograph slides and materials for electric brushes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com