Method for producing multi-color photomask and method for pattern transfer

A manufacturing method and photomask technology, which can be applied to the photolithographic process of the patterned surface, the original for photomechanical processing, semiconductor/solid-state device manufacturing, etc., which can solve the problems of uneven film reduction speed and difficult film reduction Shape control, large density difference of resist pattern, etc., achieve the effect of improving formation accuracy and improving in-plane uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

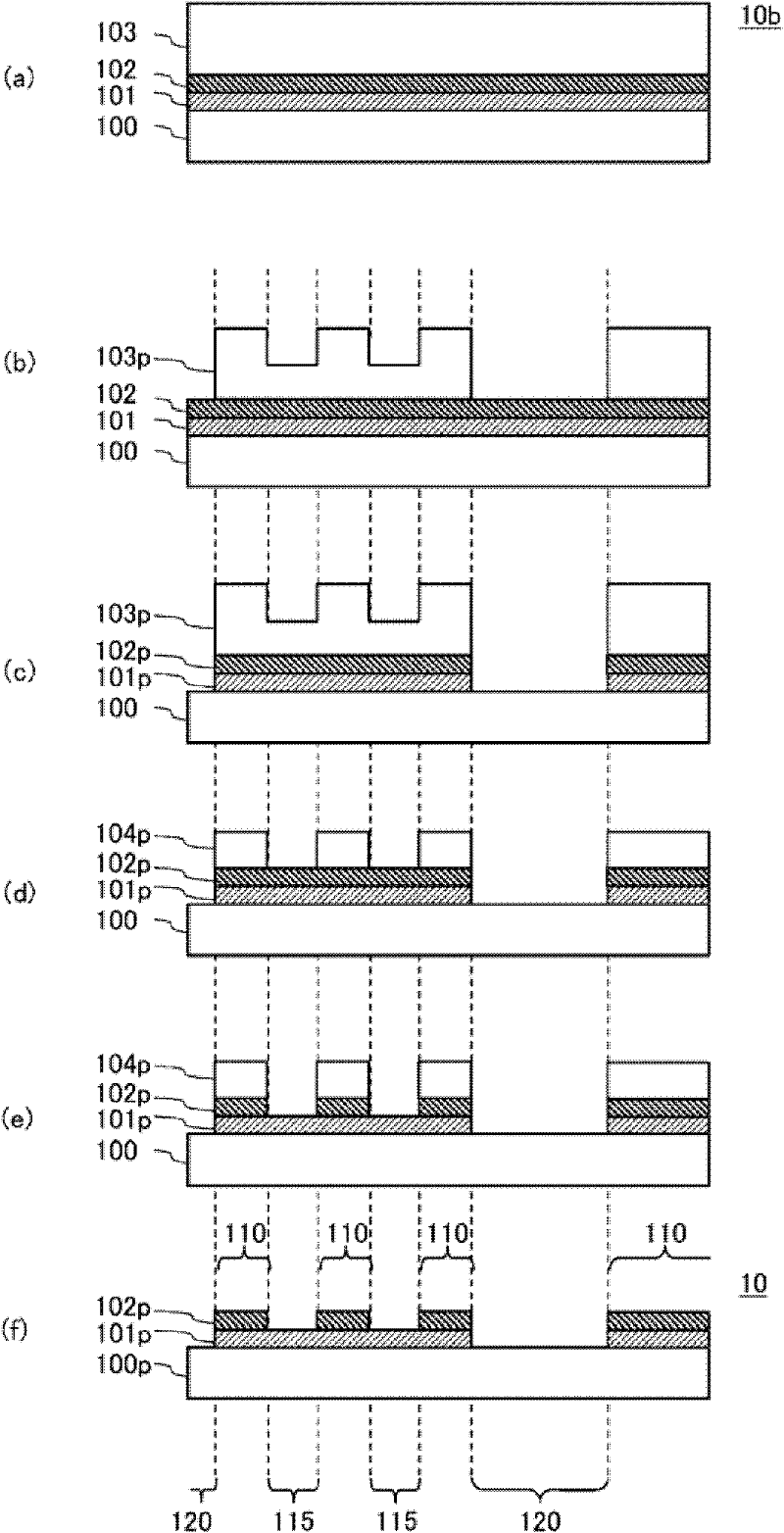

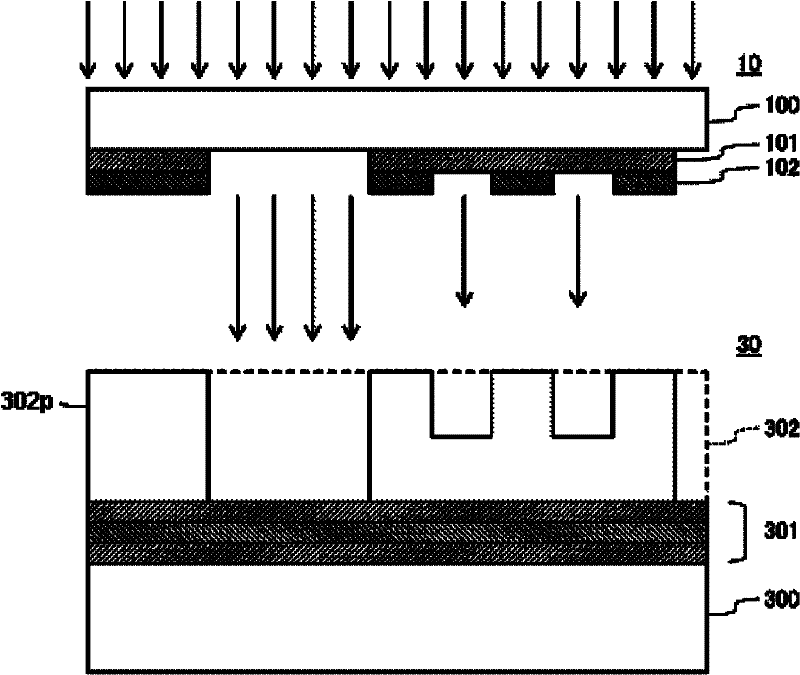

[0053] Below, refer to figure 1 and figure 2 A first embodiment of the present invention will be described. figure 1 It is a flowchart of the manufacturing process of the multi-tone photomask 10 of this 1st Embodiment. figure 2 It is a cross-sectional view showing a pattern transfer method using the multi-tone photomask 10 .

[0054] (1) Manufacturing method of multi-tone photomask

[0055] (Photomask blank preparation process)

[0056] First, as figure 1 As exemplified in (a) 1, a photomask blank 10b is prepared, which has a semi-transparent film 101 and a light-shielding film 102 formed in this order on the transparent substrate 100, and a resist film 102 is formed on the uppermost layer. Etch film 103 .

[0057] The transparent substrate 100 is formed, for example, as a flat plate made of quartz (SiO 2 ) glass, or containing SiO 2 , Al 2 O 3 , B 2 O 3 , RO (R is an alkaline earth metal), R 2 O(R 2 It is composed of low-expansion glass such as alkali metal). ...

no. 2 Embodiment approach

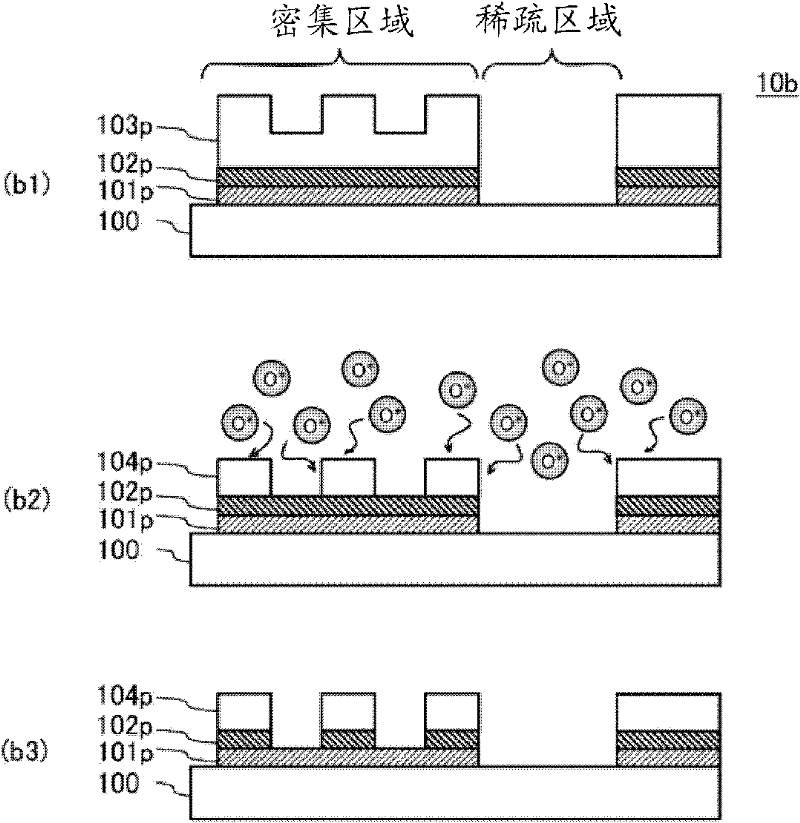

[0099] Next, a second embodiment of the present invention will be described. In the second embodiment, oxygen or ozone gas may be used instead of ozone water, and light irradiation may be performed in an environment where the gas exists, thereby realizing an excess supply state of gaseous ozone or ozone-containing active oxygen. Thereby, the difference from the above-described first embodiment is that the generation of active oxygen is promoted, thereby reducing the film of the first resist pattern 103p. Below, refer to figure 1 Differences from the above-described first embodiment will be described in detail.

[0100] The manufacturing method of the multi-tone photomask 10 of the second embodiment is also the same as that of the above-described first embodiment. figure 1 The illustrated manufacturing process, however, in the manufacturing method of the multi-tone photomask 10 according to the second embodiment, is performed by light irradiation while supplying ozone gas. f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com