Atmospheric pressure cationic dyeable polyester and its production method and use

A technology of cationic dyes and production methods, applied in the field of atmospheric pressure cationic dyeable polyester and its production and application, achieving the effects of high melting point, good heat resistance and good spinnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

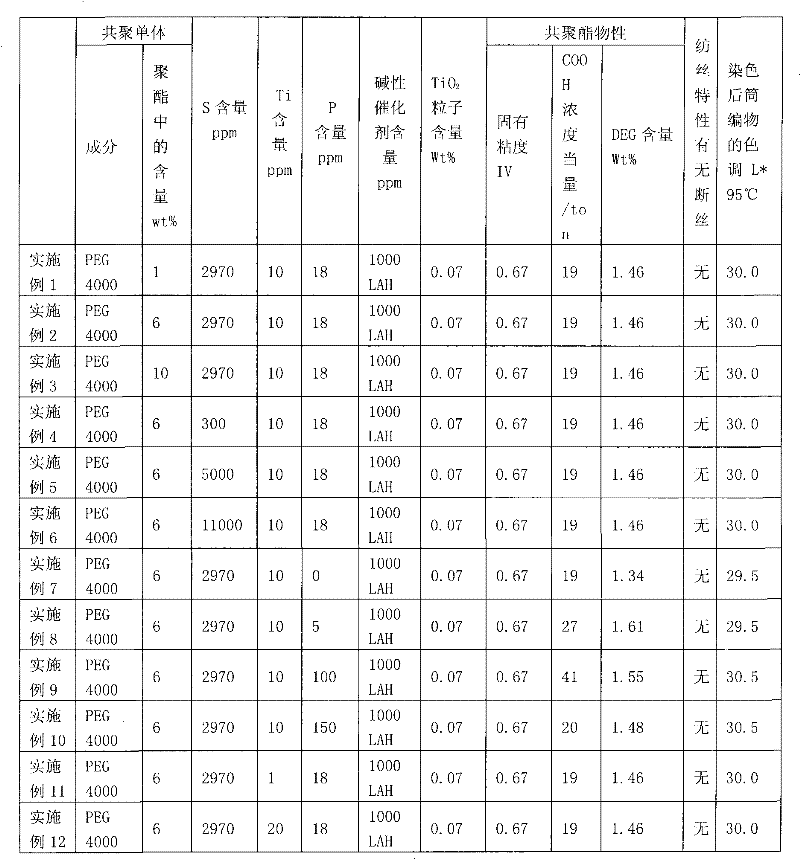

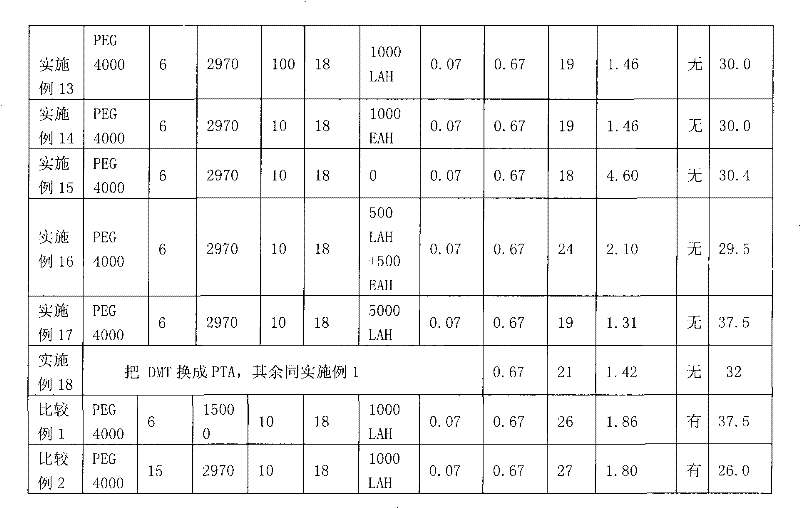

Examples

Embodiment 1

[0038] Add 15000g of DMT (dimethyl terephthalate) and 8600g of EG (ethylene glycol) into the esterification kettle, then add 415g of dimethyl isophthalate (AD2100) containing sulfonic acid groups, and then add 150g of polyethylene glycol (PEG4000) with a molecular weight of 4000, and 2.5g of catalyst titanium compound PC-50, and 90g of catalyst magnesium acetate, while adding 150g of catalyst basic lithium acetate, stirred and heated up to 240 degrees within 4 hours; Through the judgment of the by-products, when the esterification reaction rate reaches more than 97%, the prepared BHT oligomer is moved into the polymerization kettle; at room temperature, the phosphorus stabilizer trimethyl phosphate is first added, and then the matting agent titanium dioxide is added; then , carry out decompression and temperature rise, and use conventional polyester polycondensation method to carry out polymerization, so as to obtain normal pressure cationic dyeable copolymer.

[0039]The intr...

Embodiment 2

[0050] On the basis of Example 1, the addition amount of PEG4000 is controlled so that the content of the alkylene glycol group is 6%; specifically as shown in Table 1, the heat resistance of the copolyester within the scope of the present invention is good. There will be no broken filaments during the spinning process, and the fiber fabric has good dyeability.

Embodiment 3

[0052] On the basis of Example 1, the amount of PEG4000 added was controlled so that the content of the alkylene glycol group was 10%; details are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com