Method for carrying out comprehensive treatment on alumyte ore washing fine slit

A comprehensive treatment and bauxite technology, applied in the field of beneficiation tailings treatment, can solve problems such as failure to meet requirements, failure to achieve resource recycling, and low effect, to eliminate sludge stockpiling, improve utilization value, and eliminate fine sludge. stacking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

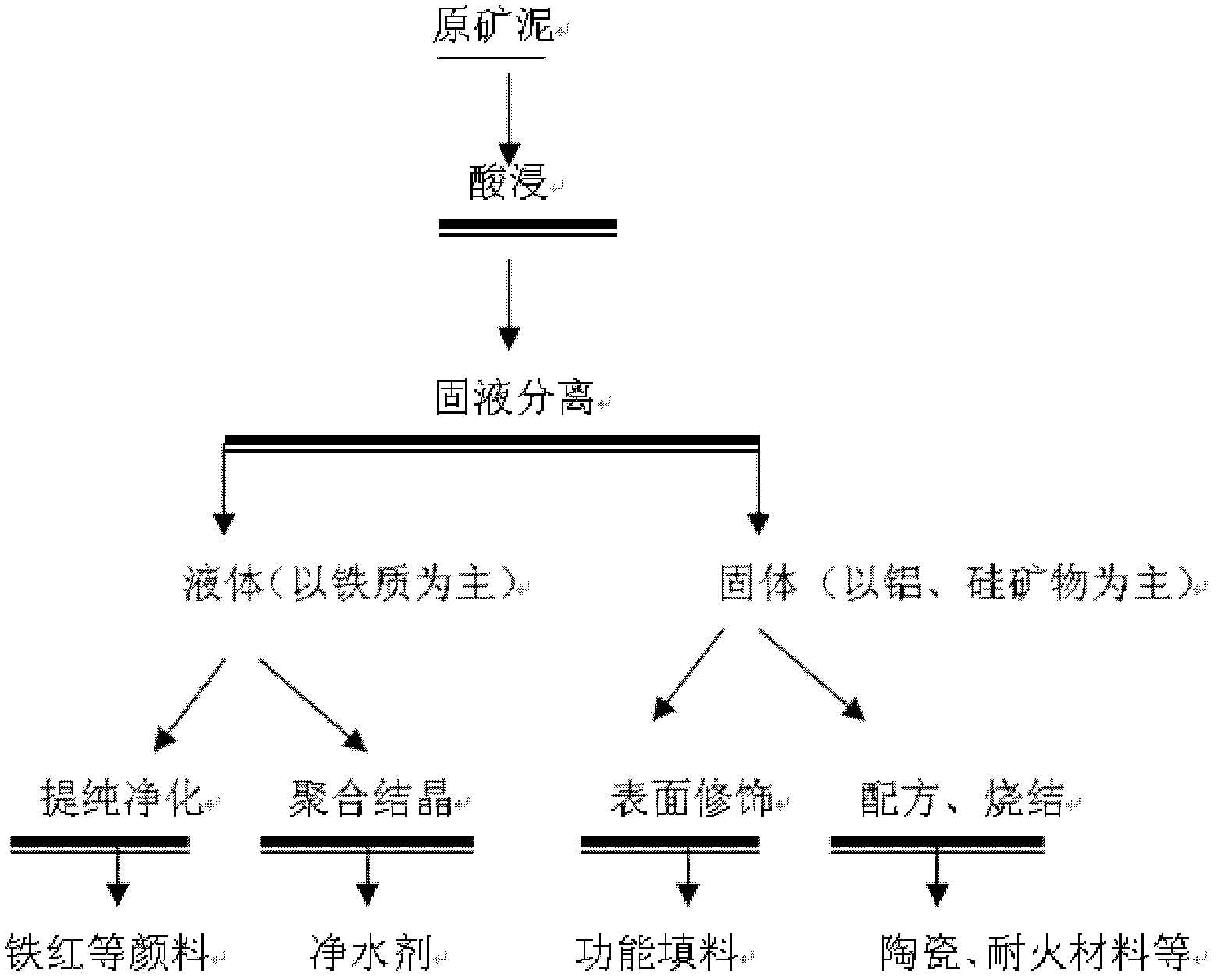

[0019] figure 1 Shown is an embodiment of a comprehensive treatment method for bauxite ore washing fine sludge of the present invention. Taking the raw ore washing fine mud of Pingguo Aluminum Mine in Guangxi as an example, the main components of the slime are: Fe15.5wt%, SiO 2 25.4wt%, Al 2 o 3 42.23wt%, its comprehensive treatment method is as follows:

[0020] (a) Concentrating the ore washing fine mud by gravity settling method so that its solid content is 30%;

[0021] (b) Add hydrochloric acid to the ore slime, adjust the acid concentration of the leaching solution to be 15%, solid-to-liquid ratio=1:3, stir and mix at a temperature of 75°C, and react for 80 minutes in acid leaching, Fe 2 o 3 The leaching rate reaches 98.5%;

[0022] (c) filter after acid leaching to obtain liquid phase and solid phase, the iron in the ore slime enters the liquid phase, and the silicon-aluminum matter enters the solid phase; After the solid phase is cleaned 3 times with 5% dilute hy...

Embodiment 2

[0027] This embodiment differs from Embodiment 1 in that:

[0028] In step (c), after the solid phase was washed 5 times with 3% dilute hydrochloric acid, then washed with tap water, Fe in the solid phase 2 o 3 reduced to 0.18%;

[0029] In step (d), after filtering, purifying and removing impurities from the liquid phase obtained in step (c), add sodium carbonate to make the pH of the solution 7.0 to 8.0, produce iron carbonate precipitation, filter and wash, and roast the filter residue at 600°C for 60 minutes , to obtain Fe-containing 2 o 3 It is 98% iron oxide red pigment product.

Embodiment 3

[0031] This embodiment differs from Embodiment 1 in that:

[0032] In step (a), its solid content of the concentrated ore slime is 35%;

[0033] In step (b), adjust the acid concentration of the leaching solution to 25%, the solid-to-liquid ratio=1:2, stir and mix at a temperature of 60° C., and react with acid leaching for 90 minutes;

[0034] In step (e), dry the solid phase obtained in step (c) and silane coupling agent in a weight ratio of solid phase: silane coupling agent = 100:02, mix and place in a ceramic ball mill for grinding for 6 hours to obtain a particle size It is an active functional filler with 100% less than 0.1mm and whiteness of 81%. The filler is used for filling modification of engineering plastics, interior and exterior wall coatings and paints, etc., on the one hand, it reduces the cost of polymer materials, and on the other hand, it can improve the shear strength and impact resistance of materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com