Etoposide long-circulating emulsion and preparation method thereof

A technology of etoposide and long-term etoposide, applied in the field of etoposide long-circulating emulsion and its preparation, can solve problems such as difficulty in drug loading, and achieve the advantages of avoiding drug degradation, reducing vascular irritation and potential toxicity, and prolonging distribution time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

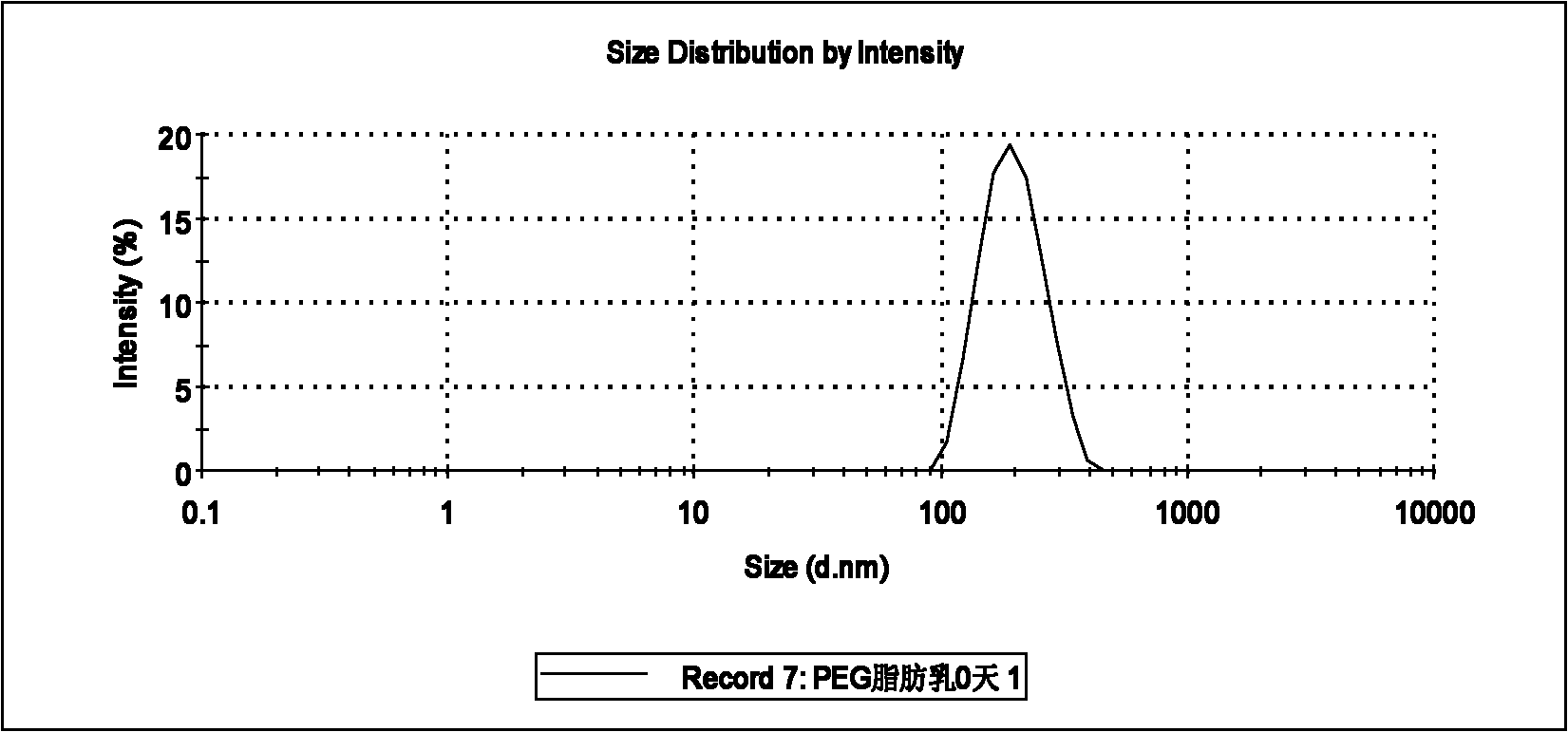

[0046] Add 1.0 g of lecithin, 0.02 g of PEG-DSPE, 0.05 g of oleic acid, and 0.01 g of etoposide into 10 g of soybean oil, and heat in an ultrasonic water bath (40° C.) to dissolve to obtain an oil phase. Take 2.25g of glycerin and dissolve it in 70ml of water for injection as the water phase. In a water bath at 50°C, add the oil phase to the water phase, stir while adding, and cut at 15,000rpm for 20min to obtain colostrum, adjust the pH to about 4.5-5, and make up the injection Water to 100ml, in a microfluidizer, the pressure 80MPa milk evenly 5 times, filling, nitrogen gas, melting seal, 121 ℃ rotary autoclaving for 10 minutes to obtain the final milk.

[0047] Average particle size = 193.7nm, PI = 0.092, encapsulation efficiency = 95.8%

Embodiment 2

[0049] Take 1.2 g of soybean lecithin, 0.1 g of PEG-DSPE, 0.10 g of oleic acid, and 0.05 g of etoposide, add them to 20 g of soybean oil, and heat them in an ultrasonic water bath (50° C.) to dissolve to obtain an oil phase. Take 2.25g of glycerin and dissolve it in 70ml of water for injection as the water phase. In a water bath at 60°C, add the oil phase to the water phase, stir while adding, and cut at 15,000 rpm for 20 minutes to obtain colostrum. Adjust the pH to about 4.5-5, and make up the injection Water to 100ml, in a microfluidizer, the pressure 80MPa milk evenly 5 times, filling, nitrogen gas, melting seal, 121 ℃ rotary autoclaving for 10 minutes to obtain the final milk.

[0050] Average particle size = 196.9nm, PI = 0.052, encapsulation efficiency = 96.7%

Embodiment 3

[0052] Get soybean oil and MCT, prepare mixed liquid oil 20g according to 1:1, get soybean lecithin 1.4g, PEG-DSPE0.4g, oleic acid 0.05g, etoposide 0.1g join in above-mentioned mixed oil phase, ultrasonic water bath heating ( 50°C) to obtain an oily phase. Take 2.25g of glycerin and dissolve it in 70ml of water for injection as the water phase. In a water bath at 70°C, add the oil phase to the water phase, stir while adding, and cut at 15,000rpm for 20min to obtain colostrum, adjust the pH to about 4.5-5, and make up the injection Water to 100ml, in a microfluidizer, the pressure 80MPa milk evenly 5 times, filling, nitrogen gas, melting seal, 121 ℃ rotary autoclaving for 10 minutes to obtain the final milk.

[0053] Average particle size = 191.7nm, PI = 0.082, encapsulation efficiency = 97.8%

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com