Simple preparation method of indium oxide nano-cube

A technology of nano-cubes and indium oxide, which is applied in the fields of chemical instruments and methods, inorganic chemistry, gallium/indium/thallium compounds, etc., can solve the problems of high equipment consumption, difficulty in realizing industrial production, long process flow of liquid phase method, etc., and achieve Low cost, mild and easy-to-control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

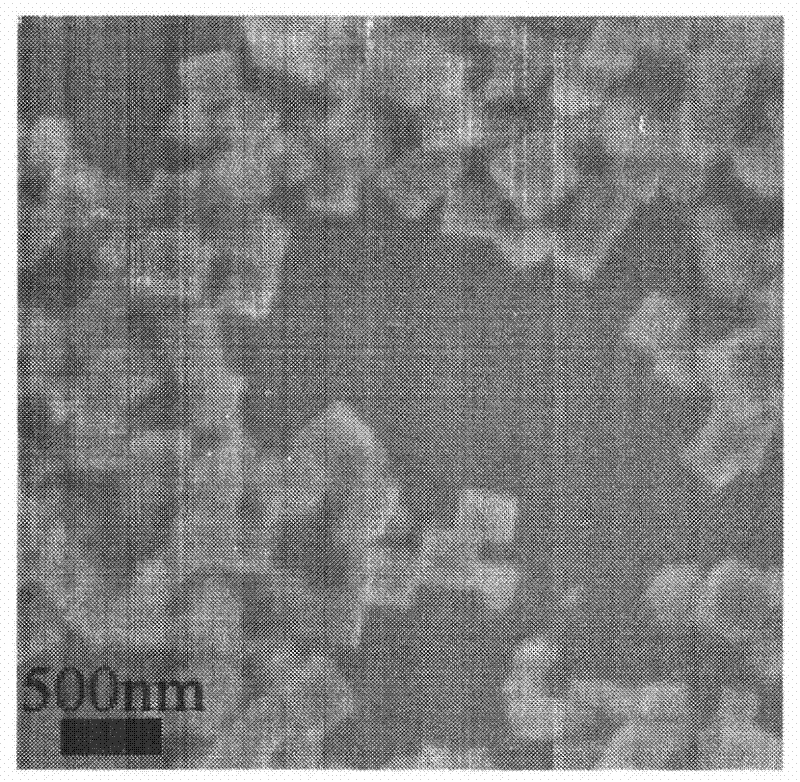

[0021] Preparation contains 0.05mol / L In 3+ The microemulsion, wherein the ratio P of the amount of alkyl polyoxyethylene ether and n-octanol is 0.38, In(NO 3 ) 3 The ratio ω of the substance amount of the aqueous solution to the alkyl polyoxyethylene ether is 10, and the rest is the content of the oil phase. Under the condition of stirring at room temperature, 0.15mol / L NaOH aqueous solution was added dropwise to In(NO 3 ) 3 In the microemulsion, keep stirring for 30 minutes after the dropwise addition, and then transfer to a 25mL polytetrafluoroethylene-lined reactor, set the reaction temperature to 140°C, and the reaction time to 12h, and naturally cool to room temperature after hydrothermal assisted reaction , a white precipitate was obtained. Centrifugal separation and washing to obtain In(OH) with a particle size of about 190nm 3 cube. Then In(OH) 3 The cube was placed in a muffle furnace and fired at 400 °C for 1.5 h to obtain In with the same shape and particle ...

Embodiment 2

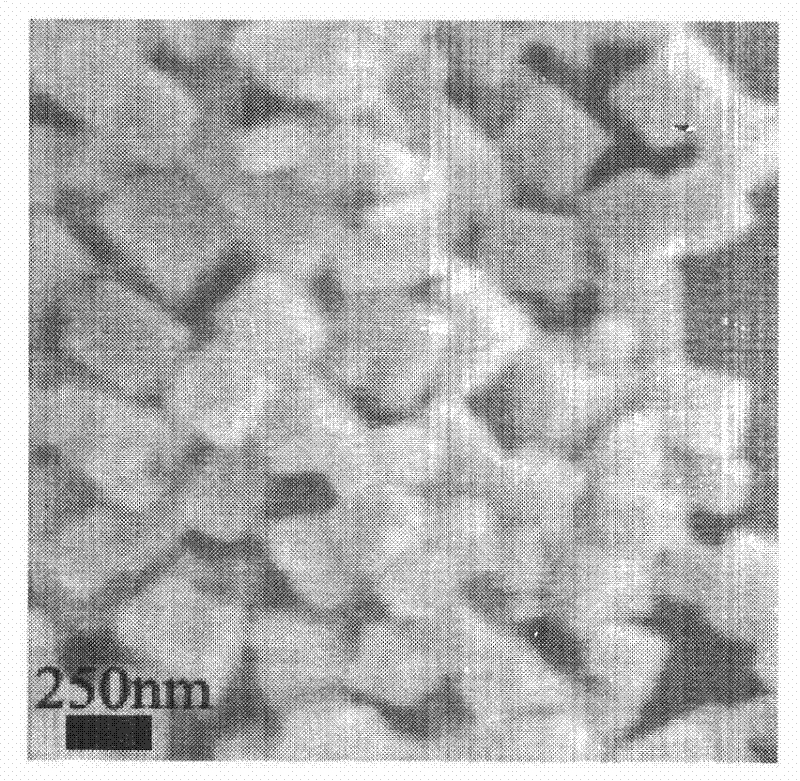

[0023] Preparation containing 0.1mol / L In 3+ The microemulsion, wherein the ratio P of the amount of alkyl polyoxyethylene ether and n-octanol is 0.38, In(NO 3 ) 3 The ratio ω of the substance amount of the aqueous solution to the alkyl polyoxyethylene ether is 10, and the rest is the content of the oil phase. Under the condition of stirring at room temperature, 0.3mol / L NaOH aqueous solution was added dropwise to In(NO 3 ) 3 In the microemulsion, keep stirring for 30 minutes after the dropwise addition, and then transfer to a 25mL polytetrafluoroethylene-lined reactor, set the reaction temperature to 140°C, and the reaction time to 12h, and naturally cool to room temperature after hydrothermal assisted reaction , a white precipitate was obtained. Centrifuge and wash to obtain In(OH) with a particle size of about 250nm 3 cube. Then In(OH) 3 The cube was placed in a muffle furnace and fired at 400 °C for 1.5 h to obtain In with the same shape and particle size. 2 o 3 n...

Embodiment 3

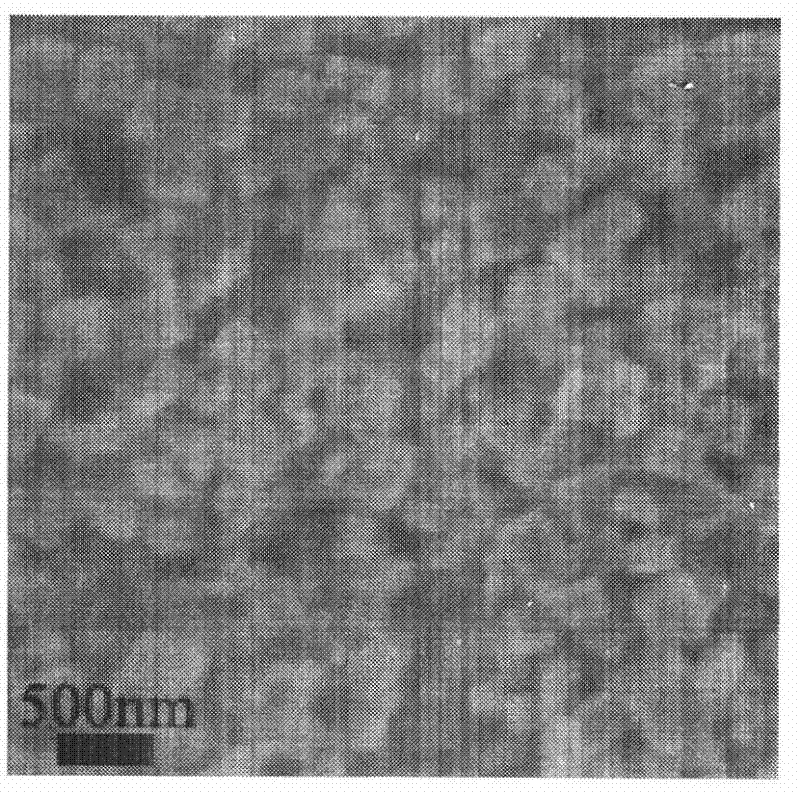

[0025] Preparation containing 0.1mol / L In 3+ The microemulsion, wherein the ratio P of the amount of alkyl polyoxyethylene ether and n-octanol is 0.38, In(NO 3 ) 3 The ratio ω of the substance amount of the aqueous solution to the alkyl polyoxyethylene ether is 20, and the rest is the content of the oil phase. Under the condition of stirring at room temperature, 0.3mol / L NaOH aqueous solution was added dropwise to In(NO 3 ) 3 In the microemulsion, keep stirring for 30 minutes after the dropwise addition, and then transfer it to a 25mL polytetrafluoroethylene-lined reactor. , a white precipitate was obtained. Centrifugal separation and washing to obtain In(OH) with a particle size of about 280nm 3 cube. Then In(OH) 3 The cube was placed in a muffle furnace and fired at 400 °C for 1.5 h to obtain In with the same shape and particle size. 2 o 3 nanocrystals, such as image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com