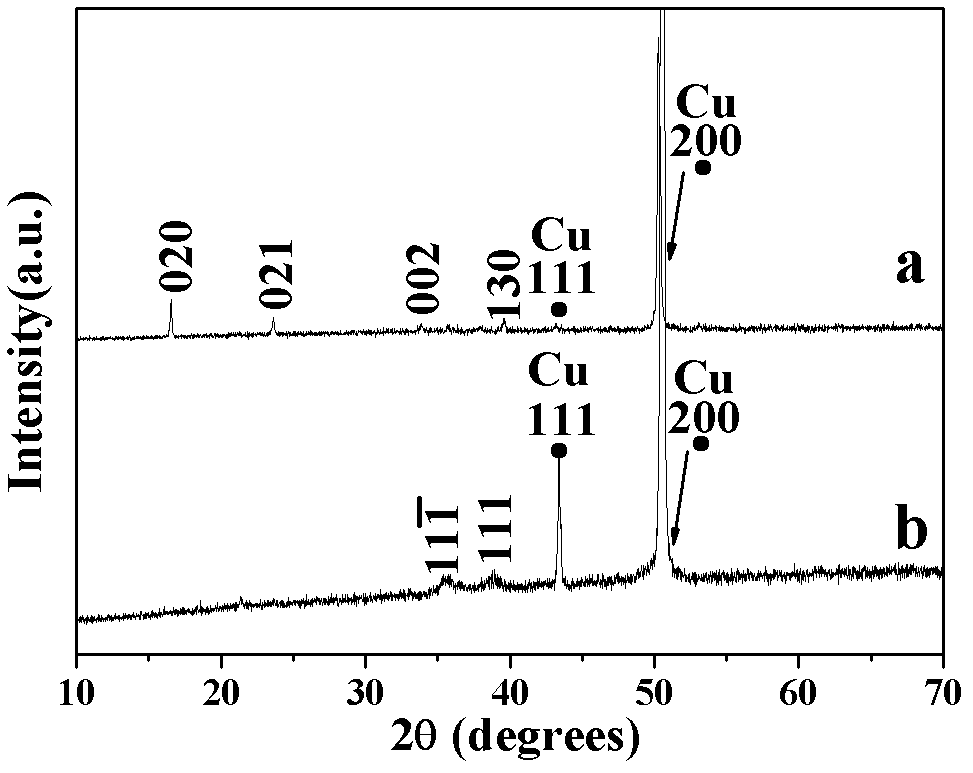

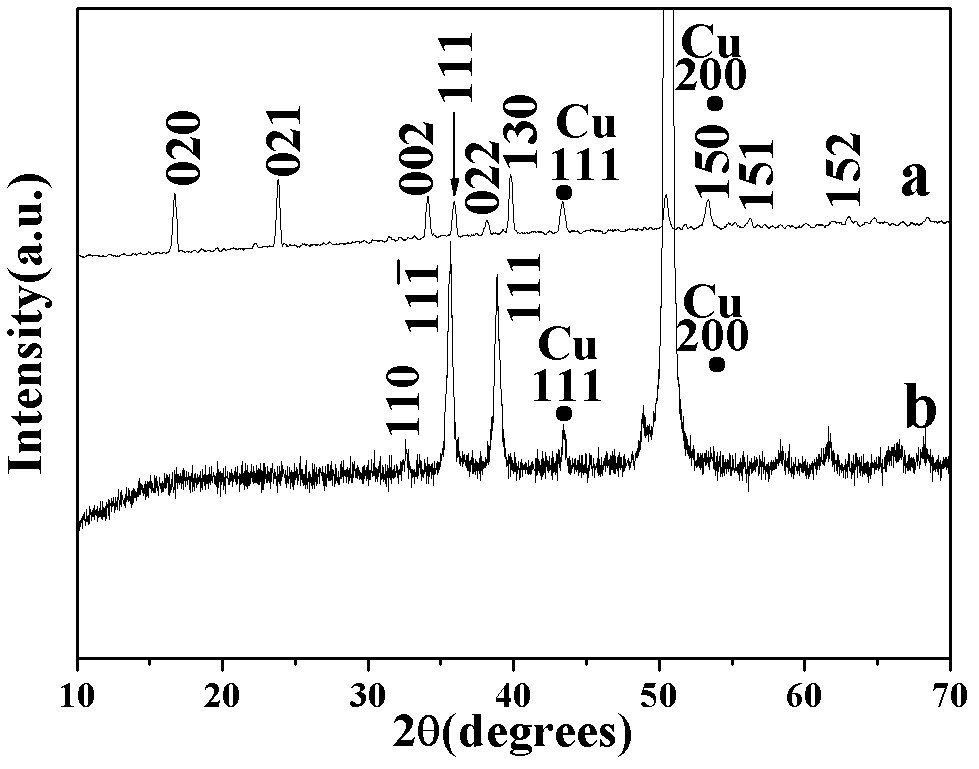

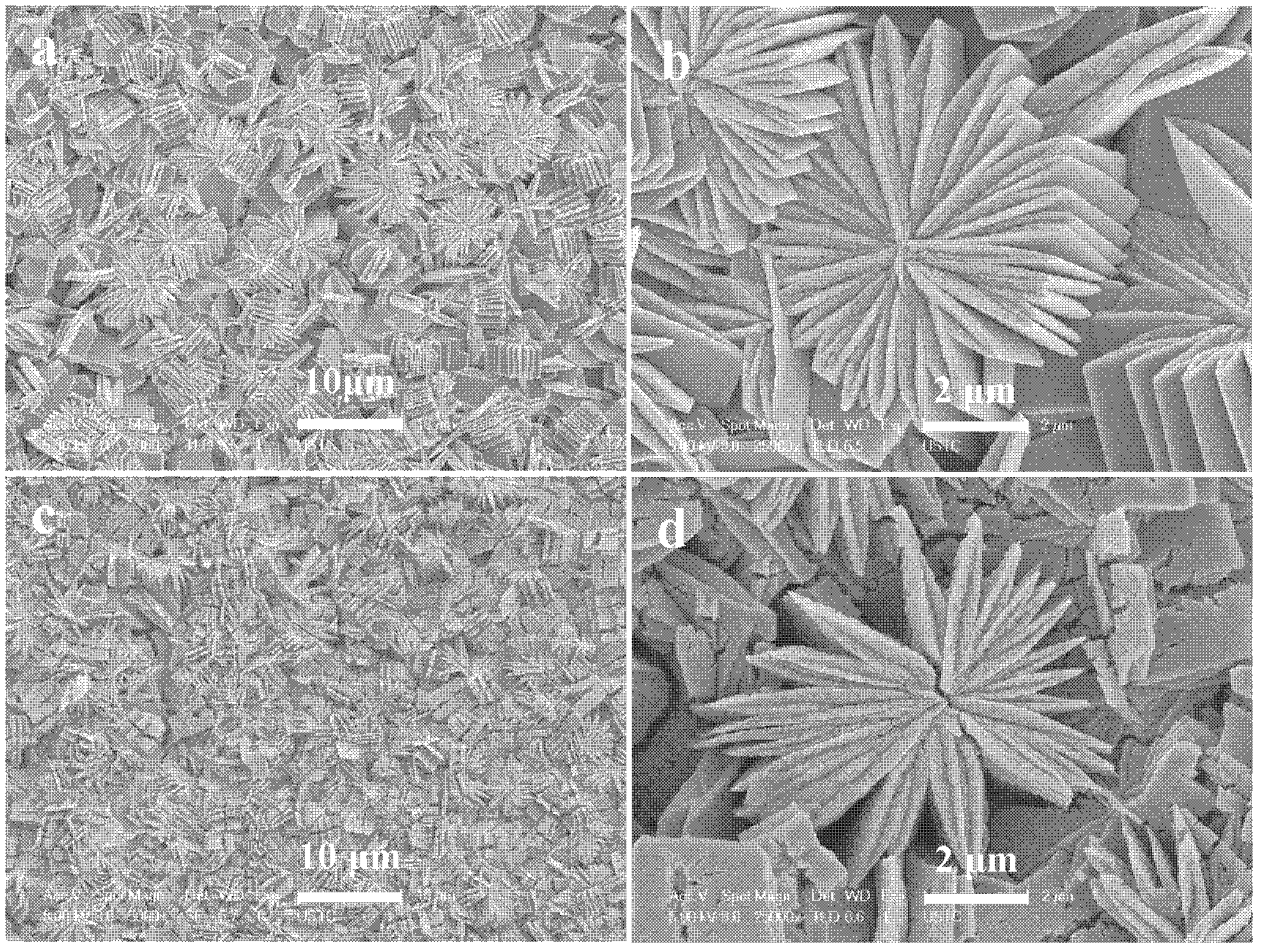

Method for preparing electrode material CuO (cupric oxide) film of lithium ion battery on copper substrate

A lithium-ion battery and electrode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of limited volume energy density, low stacking density of nanomaterials, and large electrode consumption, so as to reduce the first irreversible capacity loss , uniform film shape, and the effect of containing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Now take copper foil as the base non-limiting embodiment and describe as follows:

[0040] (1) Copper substrate pretreatment

[0041] Cut the copper substrate disc with a diameter of 1.5-1.0cm. The pretreatment of the copper substrate is to ultrasonicate the copper substrate in organic solvents such as acetone and ethanol for 10 minutes, and then place it in 2mol / L sulfuric acid solution for 10 minutes; Finally, the copper substrate is placed in 85wt% phosphoric acid solution for electrochemical polishing, and its voltage is 2-5V;

[0042] (2) Preparation of reaction solution

[0043] 1. Preparation of alkaline aqueous solution

[0044] Take 2-4mL of 10mol / L NaOH solution, add 10-20mL water to it, then add 1mol / L (NH 4 ) 2 S 2 o 8 1-2mL of the solution, and then 1-5mL of 20% ammonia water by mass, and stirred evenly to obtain 14-31mL of alkaline aqueous solution. The concentration of NaOH in alkaline aqueous solution is 1.29-1.43mol / L, (NH 4 ) 2 S 2 o 8 Conce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com