Dephosphorizing process of molybdenum nickel ore

A technology of molybdenum-nickel ore and phosphorus-molybdenum, which is applied in the field of molybdenum-nickel ore, can solve the problems of large reagent consumption, large reagent consumption, and air pollution, and achieve low reagent consumption and equipment consumption, easy process control, and high degree of mechanization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

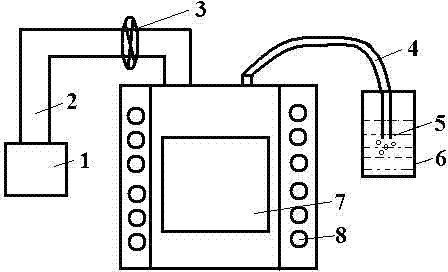

Image

Examples

Embodiment 1

[0020] Embodiment one: the preparation method and metallurgical effect of 10kg molybdenum-nickel ore, 4.23% phosphorus-content low-phosphorus molybdenum-nickel ore

[0021] The effective carbon content in the batching coke is 6.26%, that is, 0.626 kg;

[0022] Microwave parameter setting: vacuum degree in the furnace is 110Pa, frequency is 2.45GHz, power is 200kW, reduction temperature is 1020°C, reduction time is 25min;

[0023] The amount of recovered solid white phosphorus: 0.323 kg, the recovery rate of white phosphorus is 76%;

[0024] Table 1 lists the main element content in molybdenum nickel ore before and after microwave vacuum thermal reduction treatment when [P]=4.23%;

[0025] Table 1 Comparison data of main elements content in molybdenum-nickel ore before and after microwave vacuum thermal reduction treatment when [P]=4.23%

[0026] Ni Mo S P Fe C V After original 120℃ drying 8.79 12.81 42.24 4.23 16.95 13.09 1.23 After mi...

Embodiment 2

[0028] Embodiment two: the preparation method and the metallurgical effect of the low-phosphorus molybdenum-nickel ore of 20kg molybdenum-nickel ore, 5.01% phosphorus content

[0029] The effective carbon content in the coke added to the ingredients is 7.42%, that is, 0.742kg;

[0030] Microwave parameter setting: the vacuum degree in the furnace is 100Pa, the microwave frequency is 2.45GHz, the power is 450kW, the reduction temperature is 1150°C, and the reduction time is 38min;

[0031] Recovered solid white phosphorus amount: 0.755 kg, the recovery rate is 75%;

[0032] Table 2 lists the content of main elements in molybdenum-nickel ore before and after microwave vacuum thermal reduction treatment when [P]=5.01%;

[0033] Table 2 Comparison data of main elements content in molybdenum-nickel ore before and after microwave vacuum thermal reduction treatment when [P]=5.01%

[0034] Ni Mo S P Fe C V After original 120℃ drying 9.79 11.94 42.23 5...

Embodiment 3

[0036] Embodiment three: the preparation technology and the metallurgical effect of the low-phosphorus molybdenum-nickel ore of 30kg molybdenum-nickel ore and 8.75% phosphorus content

[0037] The effective carbon content in the coke added to the ingredients is 7.42%, that is, 0.742kg;

[0038]Microwave parameter setting: the vacuum degree in the furnace is 95Pa, the microwave frequency is 2.45GHz, the power is 300kW, the reduction temperature is 1100°C, and the reduction time is 30min;

[0039] Recovered solid white phosphorus amount: 1.943 kg, the recovery rate is 74%;

[0040] Table 3 lists the content of main elements in molybdenum-nickel ore before and after microwave vacuum thermal reduction treatment when [P]=8.75%;

[0041] Table 3 Contents of main elements in molybdenum-nickel ore before and after microwave vacuum thermal reduction treatment when [P]=8.75%

[0042] Ni Mo S P Fe C V After original 120℃ drying 8.92 12.18 40.35 8.75 17....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com