Method for preparing white carbon black hybridized material prepared by modification with end chlorosilane polymer

A hybrid material and polymer technology, applied in the treatment of dyed polymer organic compounds, fibrous fillers, etc., can solve the problems of unsatisfactory compatibility, blending of silica and polymers, etc., to reduce the phenomenon of agglomeration, Good economic and social benefits, the effect of improving affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

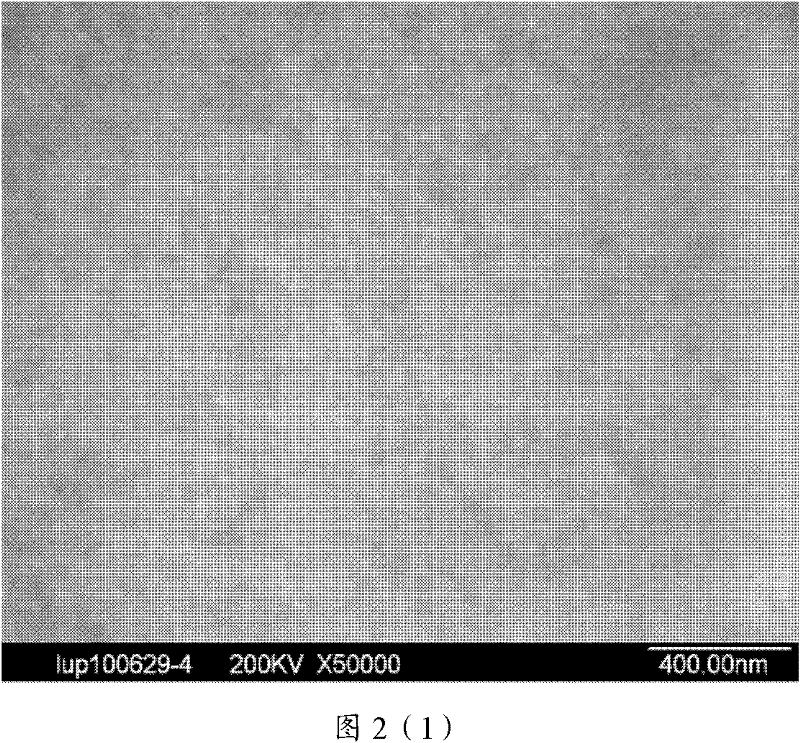

[0035] 1) Take a three-neck bottle, put C 4 h 9 SiCl 3 Formulated to 5×10 -5 mol / ml cyclohexane solution, filled with nitrogen, and set aside. Formulate tetramethylethylenediamine into 5×10 -4 mol / ml cyclohexane solution, filled with nitrogen, and set aside. Take another three-necked bottle, weigh 100g of fumed silica and put it into it, then place the three-necked bottle in a vacuum oven at 120°C with a relative vacuum pressure of about 0.1MPa and bake for 2 hours, then fill it with nitrogen, and set it aside.

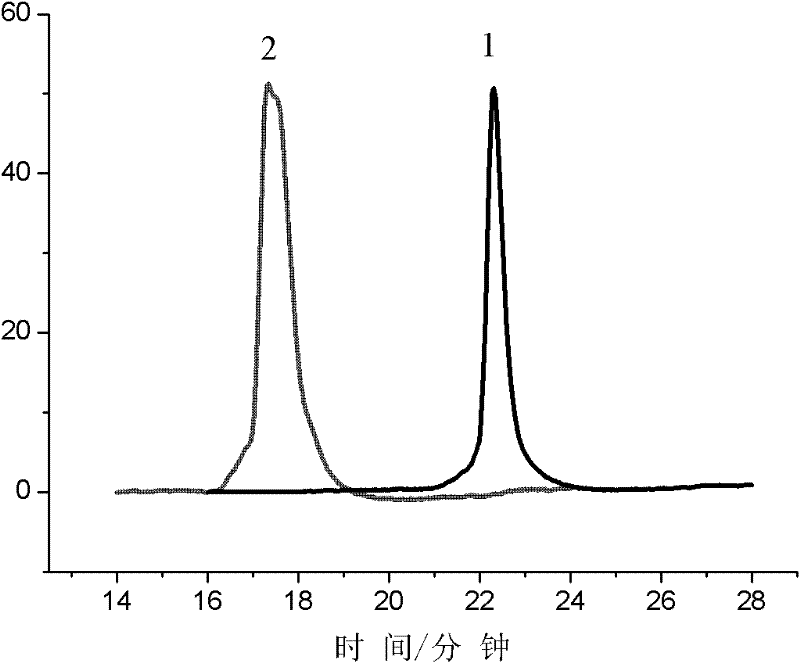

[0036] 2) Add 20 g of anionic active butadiene-styrene random polymer into a 250 ml three-necked bottle, and sample 1. Use a pipette to take 23.5ml of C 4 h 9 SiCl 3 The cyclohexane solution was added into the polymerization bottle, and reacted at 30°C for 10 minutes to obtain a terminal chlorosilylated polymer, sample 2.

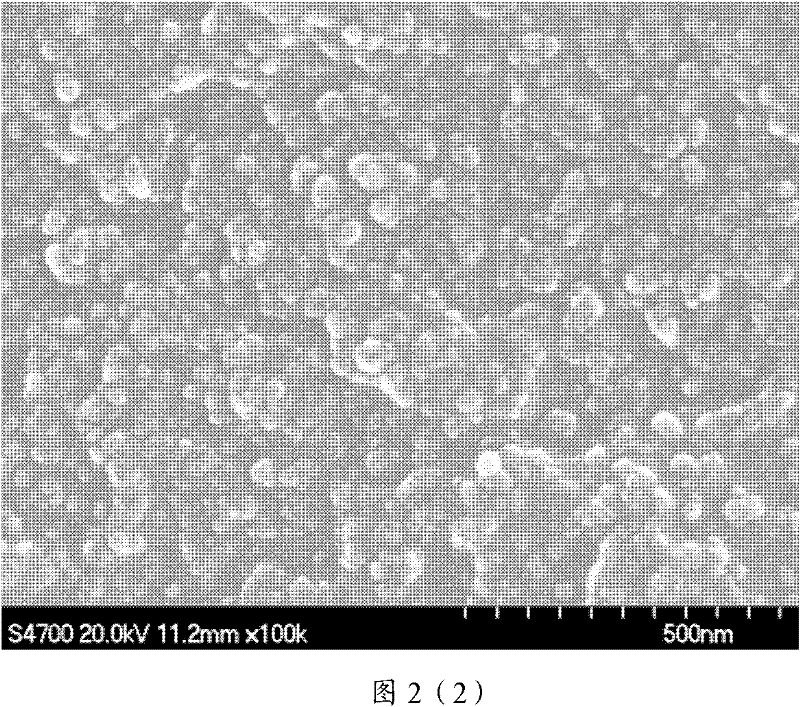

[0037] 3) Take a cyclohexane solution containing 10 g of a terminal chlorosilylated polymer and add it to 100 g of white carbon black, mi...

Embodiment 2

[0042] 1) Take a three-neck bottle, put CH 3 SiCl 3 Formulated to 5×10 -5 mol / ml cyclohexane solution, filled with nitrogen, and set aside. Make triethylamine into 5×10 -4 mol / ml cyclohexane solution, filled with nitrogen, and set aside. Take another three-necked bottle, weigh 80g of precipitated silica and put it into it, then place the three-necked bottle in a vacuum oven at 120°C with a relative vacuum pressure of about 0.1MPa and bake for 2 hours, then fill it with nitrogen, and set it aside.

[0043] 2) Add 20 g of anionic active butadiene-styrene random polymer into a 250 ml three-necked flask, and sample 1. Take 18.6ml CH with a pipette 3 SiCl 3 The cyclohexane solution was added into the polymerization bottle, and reacted at 40°C for 10 minutes to obtain a terminal chlorosilylated polymer, sample 2.

[0044] 3) Take 10 g of the obtained terminal chlorosilylated polymer / cyclohexane and add it to 80 g of white carbon black, mix well, and add 1.9 ml of triethylamin...

Embodiment 3

[0049] 1) Take a three-neck bottle, put CH 3 SiCl 3 Formulated to 5×10 -5 mol / ml cyclohexane solution, filled with nitrogen, and set aside. Take another three-necked bottle, weigh 20g of fumed silica and put it into it, then place the three-necked bottle in a vacuum oven at 120°C with a relative vacuum pressure of about 0.1MPa and bake for 2 hours, then fill it with nitrogen, and set it aside.

[0050] 2) Add 20 g of anionic active butadiene-styrene random polymer into a 250 ml three-necked flask, and sample 1. Take 13ml CH with a pipette 3 SiCl 3 The cyclohexane solution was added into the polymerization bottle, and reacted at 50°C for 10 minutes to obtain a terminal chlorosilylated polymer, sample 2.

[0051] 3) Take 10 g of the prepared cyclohexane of the terminal chlorosilylated polymer, add 20 g of white carbon black into it, mix well, and react for 5 hours. Reaction conditions: heating in a water bath at 50° C., and the whole reaction process is carried out under ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com