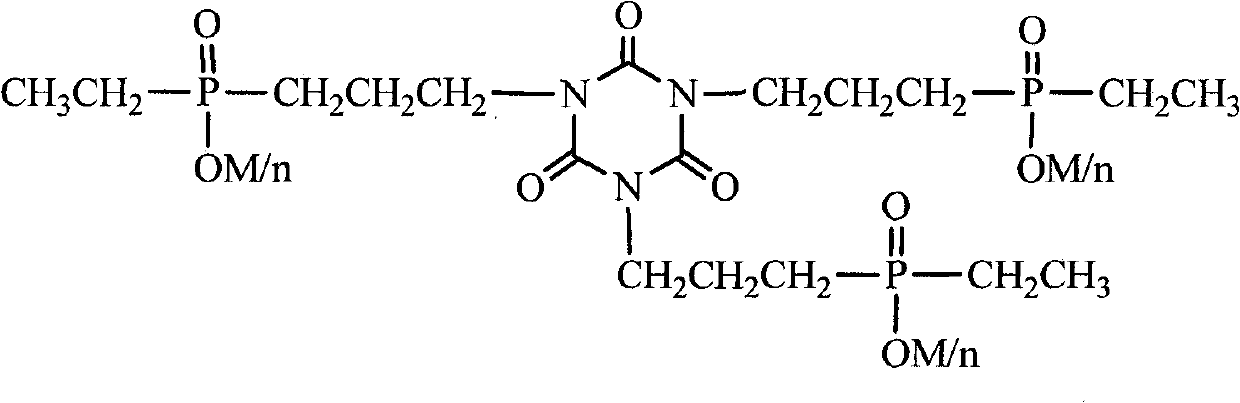

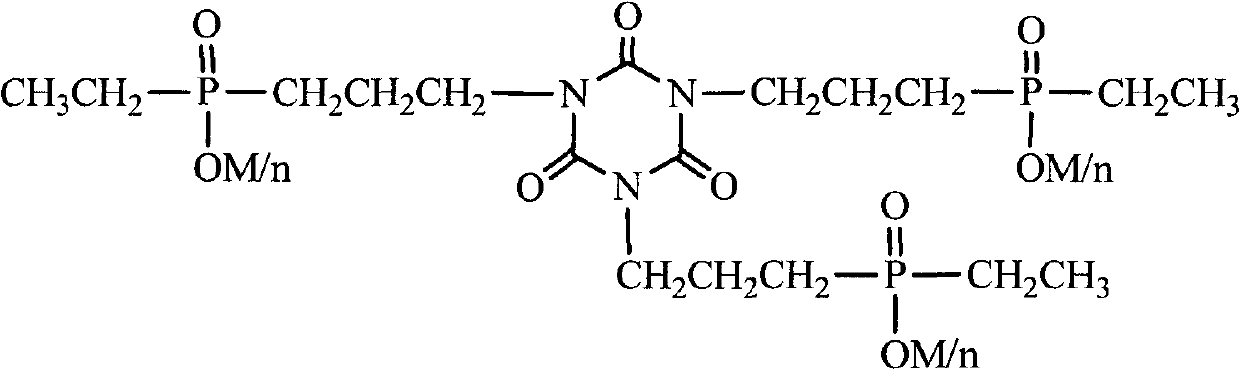

Organic phosphinic acid metal salt containing triazine ring and preparation method thereof

The technology of metal phosphinic acid salt and triazine ring is applied in the field of metal organic phosphinic acid salt and its preparation, which can solve the problems of high molecular polarity, influence on flame retardant performance, decrease in mechanical properties of materials, etc., and achieve good dispersibility. , the molecular weight is large, the effect of improving the flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

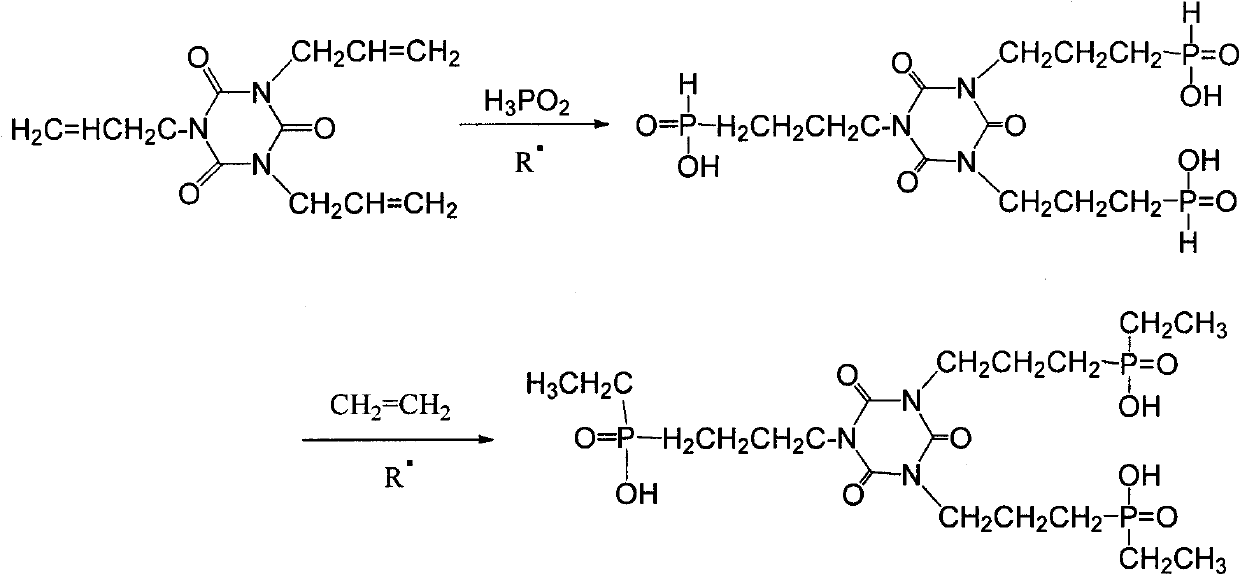

Method used

Image

Examples

Embodiment 1

[0037] Example 1 Add 1188g of 50% hypophosphorous acid aqueous solution and 3L of acetic acid to a 10L three-necked flask equipped with a stirrer, a thermometer, and a reflux condenser, stir and heat to 90°C, and uniformly inject and dissolve 748g (3mol) of isocyanurate within 10h Acetate triallyl ester and 40g acetic acid solution of tert-butyl peroxy benzoate, control the reaction temperature not to exceed 95°C, and keep stirring for 1 hour after the injection of the solution is completed. Transfer the liquid in the flask to a 20L high-pressure reactor, seal it, exhaust the air in the reactor, heat to 90°C, feed ethylene, set the pressure to 0.6MPa through the pressure reducing valve on the ethylene cylinder, and set the pressure at a constant Pump 5% acetic acid solution of tert-butyl benzoate peroxide at a high speed, control the temperature in the reactor with cooling water to not exceed 95°C until the consumption of ethylene no longer increases, stop pumping the initiator...

Embodiment 2

[0038] Example 2 Add 954g (9mol) of sodium hypophosphite monohydrate and 3L of acetic acid into a 10L three-necked flask equipped with a stirrer, a thermometer, and a reflux condenser, stir and heat to 115°C, and uniformly inject and dissolve 785g (3.15mol) of sodium hypophosphite in 10 hours. ) acetic acid solution of triallyl isocyanurate and 50 g of benzoyl peroxide, control the reaction temperature not to exceed 120° C., and keep stirring for 1 hour after the injection of the solution is completed. Transfer the liquid in the flask to a 20L high-pressure reactor, seal it, exhaust the air in the reactor, heat it to 115°C, feed ethylene, set the pressure to 0.6MPa through the pressure reducing valve on the ethylene cylinder, and set the pressure at a constant Pump 5% benzoyl peroxide acetic acid solution at high speed, control the temperature in the reactor not to exceed 120°C with cooling water until the consumption of ethylene no longer increases, stop pumping the initiator ...

Embodiment 3

[0039]Example 3 Add 954g (9mol) of sodium hypophosphite monohydrate and 3L of acetic acid into a 10L three-necked flask equipped with a stirrer, a thermometer, and a reflux condenser, stir and heat to 100°C, and uniformly inject and dissolve 823g (3.3mol) of sodium hypophosphite in 10 hours. ) acetic acid solution of triallyl isocyanurate and 30 g of azobisisoheptanonitrile, the reaction temperature is controlled not to exceed 105° C., and the solution is kept for 1 hour after injection. Transfer the liquid in the flask to a 20L high-pressure reactor, seal it, exhaust the air in the reactor, heat it to 100°C, feed ethylene, and set the pressure to 0.6MPa through the pressure reducing valve on the ethylene cylinder, at a constant Pump in 5% azobisisoheptanonitrile acetic acid solution at high speed, control the temperature in the reactor not to exceed 105°C with cooling water until the consumption of ethylene no longer increases, stop pumping the initiator solution, keep the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com