Numerical control multifunctional horizontal wrapping machine

A multi-functional, wrapping machine technology, applied in the direction of electromechanical devices, transportation and packaging, manufacturing motor generators, etc., can solve the problems of reducing the service life of the controller, failing to achieve the cooling effect, uneven product surface, etc., to achieve enhanced adhesion sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

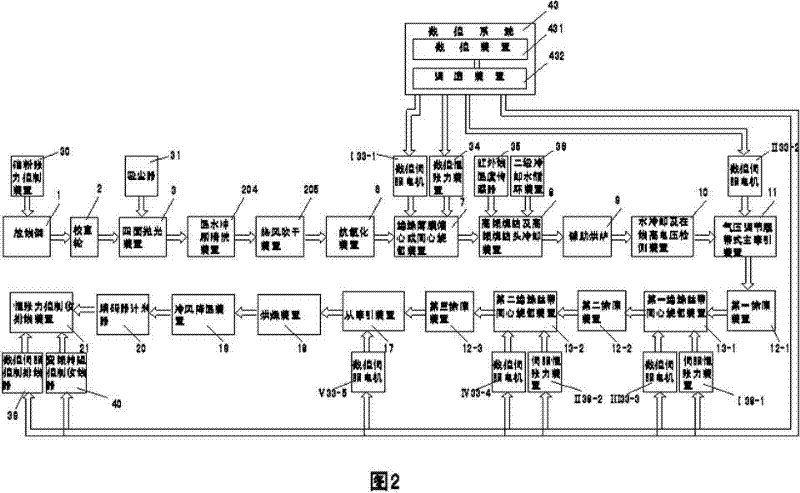

[0023] refer to figure 2 , this embodiment includes an electric constant tension pay-off rack 1, a straightening wheel 2, a four-sided polishing device 3, a warm water washing device 204, a hot air drying device 205, an anti-oxidation device 6, and a CNC servo motor 33-1 and NC constant tension device 34, insulating film eccentric or concentric wrapping device 7, high-frequency sintering and high-frequency sintering head cooling device 8 with infrared temperature sensor 35 and secondary cooling water device 36 installed, auxiliary oven 9 , water cooling and on-line high voltage detection device 10, air pressure adjustment crawler type main traction device 11, first painting device 12-1, equipped with CNC servo motor 33-3 and servo constant tension device 38-1 first insulating ribbon concentric wrapping device 13-1, second painting device 12-2, equipped with CNC servo motor 33-4 and servo constant tension device 38-2 second insulating ribbon concentric wrapping device 13...

Embodiment 2

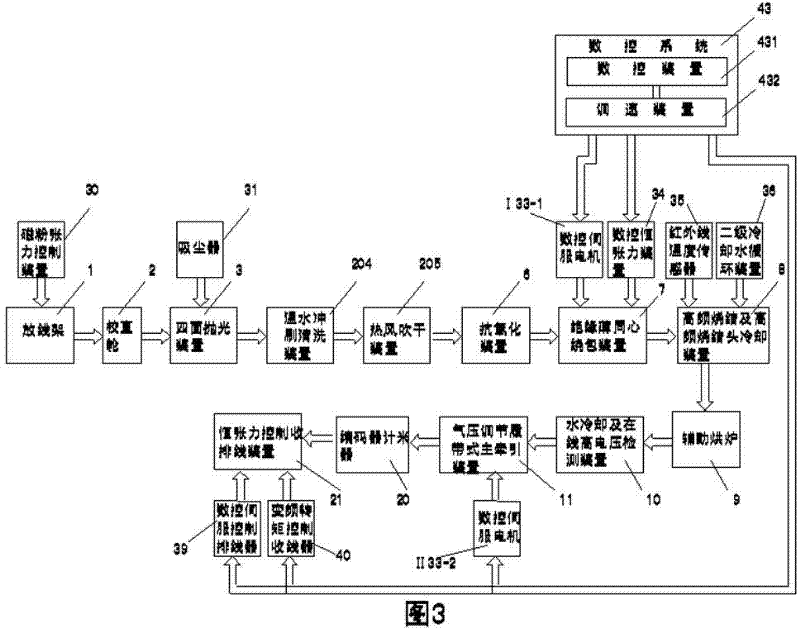

[0039] refer to image 3 , the difference between this embodiment and Embodiment 1 is that the present embodiment does not have a first painting device 12-1, and a numerically controlled servo motor is installed. 33-3 and servo constant tension device 38-1 first insulating ribbon concentric wrapping device 13-1, second painting device 12-2, equipped with CNC servo motor 33-4 and servo constant tension device The second insulating ribbon concentric wrapping device 13-2 of 38-2, the third painting device 12-3, the slave pulling device 17, the drying device 18, and the cold air cooling device 19 form a film sintering machine.

Embodiment 3

[0041] refer to Figure 4 The difference between this embodiment and Embodiment 1 is that the present embodiment does not have a high-frequency sintering and a high-frequency sintering head cooling device 8, an auxiliary oven 9, a water cooling device 36 equipped with an infrared temperature sensor 35 and a secondary cooling water device 36. The cooling and online high voltage detection device 10 forms a film wire wrapping machine.

[0042]In the present invention, the electrical constant tension winding method is used to solve the problems of wire core pull and pitch drift caused by unstable tension; the surface of the copper wire is cleaned by warm water and high pressure washing, which can completely clean the oil on the surface of the copper wire , strengthen the adhesion between the bare copper wire and the insulating film; use infrared to measure the surface temperature of the sintering line and feed it back to the control instrument to control the sintering temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com