Device for recycling silicon powder and waste water from waste water from silicon cutting and method thereof

A waste water recovery and silicon cutting technology, which is applied in chemical instruments and methods, energy waste water treatment, water/sewage multi-stage treatment, etc., can solve the problems of failing to meet waste water standards or zero discharge, secondary pollution of the environment, and high operating costs. Achieve the effects of improving resource utilization, low operating costs, and alleviating environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

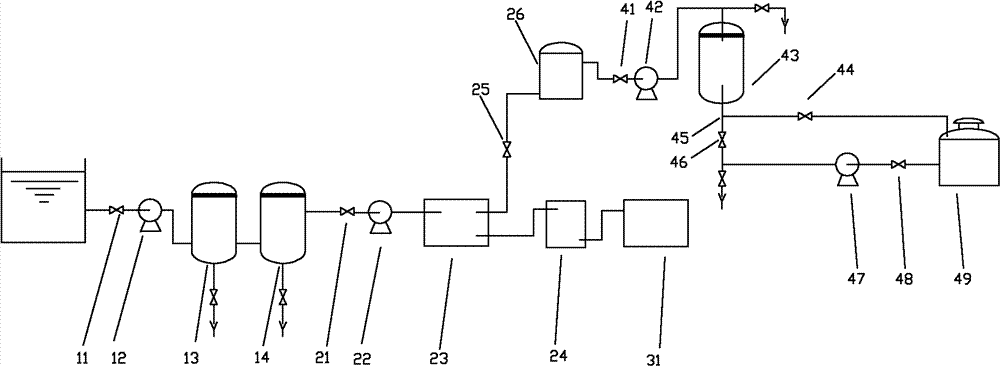

Image

Examples

Embodiment 1

[0040] 1000 tons / day silicon powder and wastewater recycling project in silicon cutting wastewater.

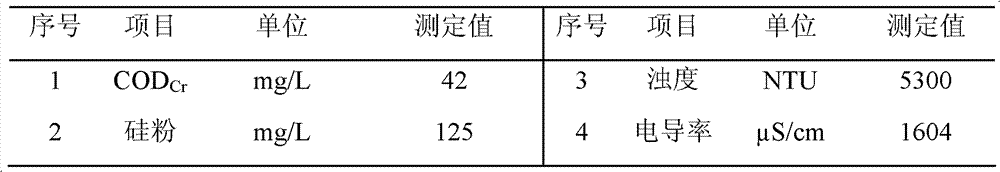

[0041] The water quality of the silicon cutting wastewater is shown in Table 1.

[0042] Table 1 Water quality of silicon cutting wastewater

[0043]

[0044] Step 1. Electrolysis: start the water supply pump 12, and the sewage is 50m 3 The flow rate per hour enters the electrolysis machine 13 through the stop valve 11 for electrolysis, and then enters the buffer tank 14 for precipitation. The working voltage of the electrolysis machine is 12V, the voltage between the two poles is 3.5~8.0V, and the current density is 80mA / cm 2 , The residence time of wastewater in the electrolysis machine is 9-15min. Under the action of electric current, the nascent hydroxyl [OH] and nascent oxygen [O] and other strong oxidizing substances produced by electrolysis oxidize and decompose the organic matter in the wastewater to reduce COD , And make the suspended solids, colloids, and charged particles...

Embodiment 2

[0056] 2000 tons / day silicon powder and waste water recycling project in silicon cutting wastewater.

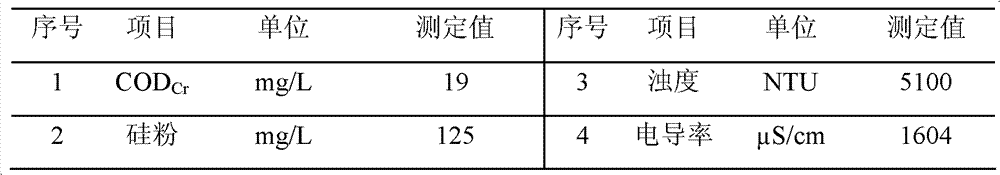

[0057] The water quality of the silicon cutting wastewater is shown in Table 4.

[0058] Table 4 Water quality of silicon cutting wastewater

[0059]

[0060] Step 1. Electrolysis: start the water supply pump 12, and the silicon cutting waste water is 100m 3 The flow rate per hour enters the electrolysis machine 13 through the stop valve 11 for electrolysis, and then enters the buffer tank 14 for precipitation. The working voltage of the electrolysis machine is 18V, the voltage between the two poles is 3.5~5.0V, and the current density is 120mA / cm 2 , The residence time of wastewater in the electrolysis machine is 5-8min. Under the action of electric current, the nascent hydroxyl [OH] and nascent oxygen [O] and other strong oxidizing substances produced by electrolysis oxidize and decompose the organic matter in the wastewater, and reduce COD , And make the suspended solids, colloi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com