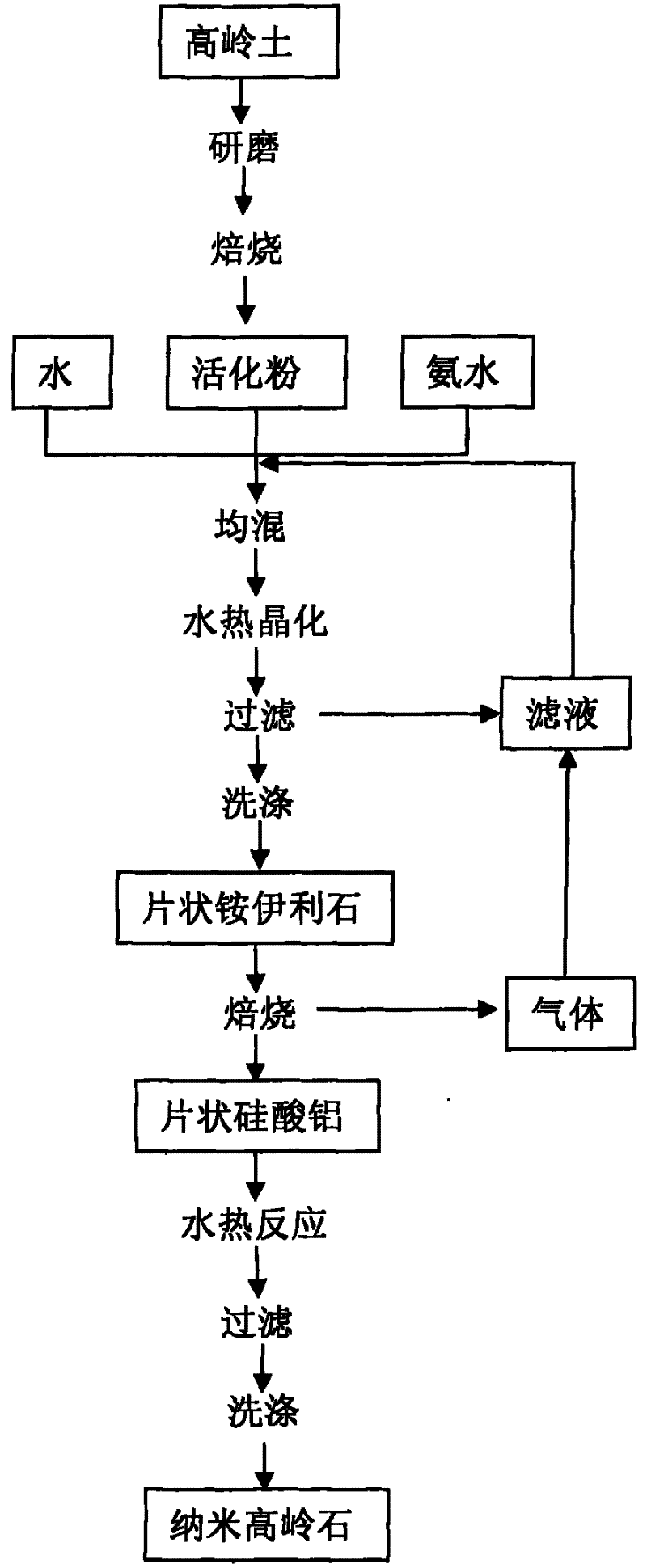

Method for preparing ammonium illite sheets, alumina silicate sheets, and nano-sized kaolinite

A technology of flaky ammonium and illite, applied in the direction of aluminum silicate, chemical instruments and methods, silicates, etc., can solve the problem of uneven intercalation rate and effect, large changes in particle size and shape of intercalation products, nanometer Problems such as high cost of kaolin, to achieve the effect of easy realization and widening of kaolin deep-processing products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Coal series kaolin, with kaolinite content of 92.5%, loss on ignition of 17.2%, crushed and ground to an average particle size of less than 2μm. Use a muffle furnace to roast at 800° C. for 2 hours, take 20 g of roasted activated powder, add 150 ml of water, and 50 ml of 25% concentrated ammonia water and mix to obtain a slurry.

[0046] Put the above slurry into a 500ml resin ball mill tank, add 200g of zirconium silicate balls with a diameter of 6mm, and mill for 4 hours at a speed of 400r / min to form a slurry to be hydrothermally reacted.

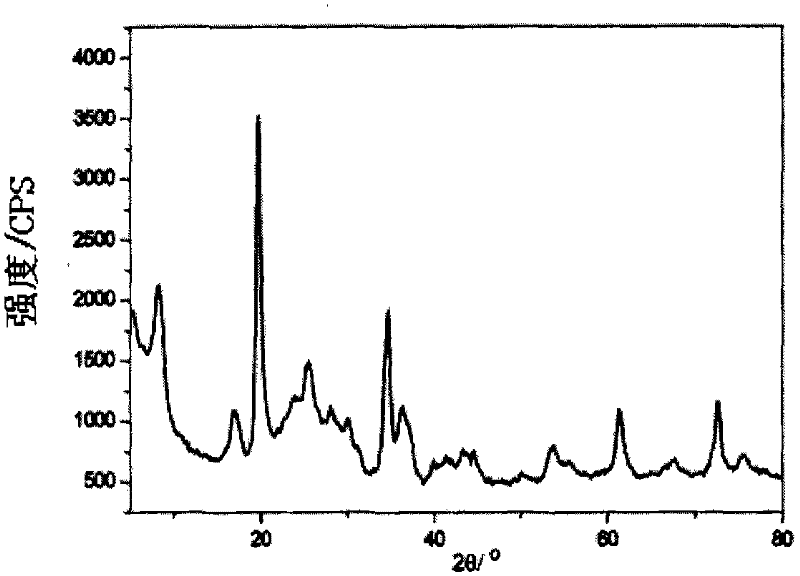

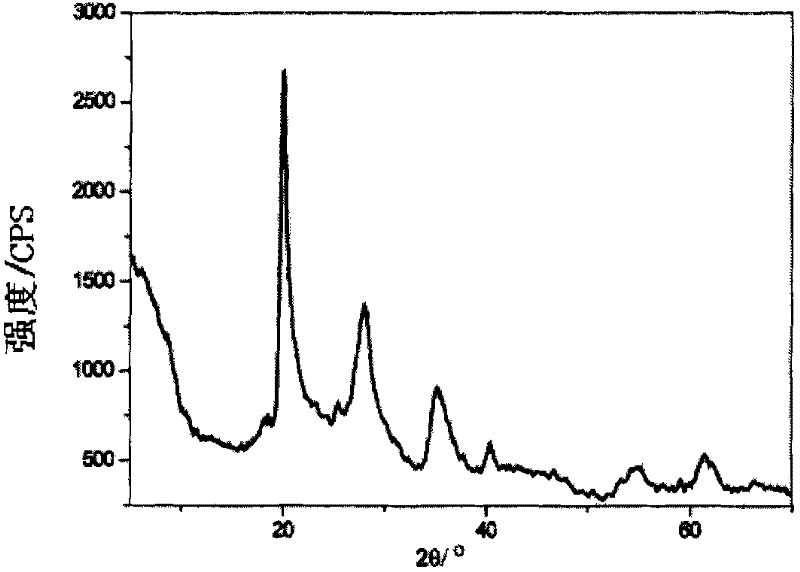

[0047] Pour the above-mentioned slurry to be hydrothermally reacted into a PTFE-lined 500ml pressure reactor, and conduct a hydrothermal reaction at 200°C for 96 hours; cool the hydrothermally reacted slurry to room temperature and suction filter, and wash the solid with industrial ethanol Twice, dry in an oven at 120°C for 3 hours to obtain flaky ammonium illite. The XRD diffraction pattern of gained ammonium illite is as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com