Nylon 6 resin, nylon 6 filament and preparation methods thereof

A technology of nylon and resin, applied in the field of spinning materials, to achieve stable fiber performance, reduce impact, and reduce crystallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045]

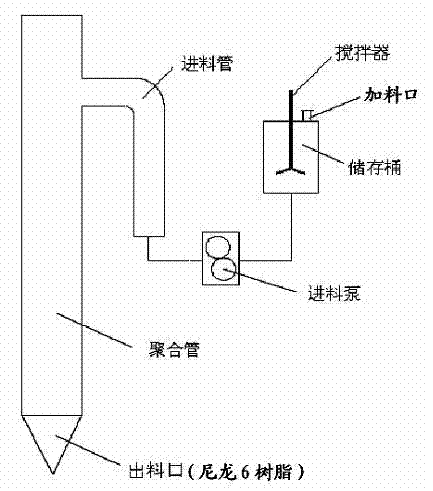

[0046] like figure 1 Shown: Stir and mix the above materials in the storage tank evenly, and continuously send the above materials into the straight VK pipe through the feed pump, and the materials are polymerized by the ring-opening agent. The temperature control in the polymerization reaction is divided into three parts In the first stage, the material is in the upper section of the straight VK tube, and the temperature is controlled between 250 and 260°C; in the middle section of the straight VK tube, the temperature is controlled between 235 and 245°C; in the lower section of the straight VK tube, the temperature is controlled between 230 and 235°C In between, the polymer melt flows down to the bottom of the VK tube through layers of baffles, and is taken out by the discharge pump to maintain the liquid level in the tube. The polymerization time is 10 hours. The obtained polymer melt is washed with water, cut into pellets, and dried in vacuum to remove moisture...

Embodiment 2

[0050]

[0051] like figure 1 Shown: Stir and mix the above materials in the storage tank evenly, and continuously send the above materials into the straight VK pipe through the feed pump, and the materials are polymerized by the ring-opening agent. The temperature control in the polymerization reaction is divided into three parts In the first stage, the material is in the upper section of the straight VK tube, and the temperature is controlled between 255 and 265°C; in the middle section of the straight VK tube, the temperature is controlled between 240 and 250°C; in the lower section of the straight VK tube, the temperature is controlled at 235 Between ~240°C, the polymer melt flows down through layers of baffles to the bottom of the VK tube, and is taken out by the discharge pump to maintain the liquid level in the tube. The polymerization time is 14 hours. The obtained polymer melt is washed with water, cut into pellets, and dried in vacuum to remove moisture and small ...

Embodiment 3

[0055]

[0056] like figure 1Shown: Stir and mix the above materials in the storage tank evenly, and continuously send the above materials into the straight VK pipe through the feed pump, and the materials are polymerized by the ring-opening agent. The temperature control in the polymerization reaction is divided into three parts In the first stage, the material is in the upper section of the straight VK tube, and the temperature is controlled between 260-268°C; the middle section of the straight VK tube, the temperature is controlled between 243-253°C; the temperature in the lower section of the straight VK tube is controlled at 238-248°C During this process, the polymer melt flows down to the bottom of the VK tube through layers of baffles, and is taken out by the discharge pump to maintain the liquid level in the tube. The polymerization time is 18 hours. The obtained polymer melt is washed with water, cut into pellets, and dried in vacuum to remove moisture and small mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com