Preparation method for lignosulfonic acid iron and manganese salt

A technology of ferric manganese sulfonate and lignin sulfonic acid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the time-consuming and labor-intensive problems of the preparation process, achieve simple procedures, reduce material loss, and reduce calcium Effect of ion content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

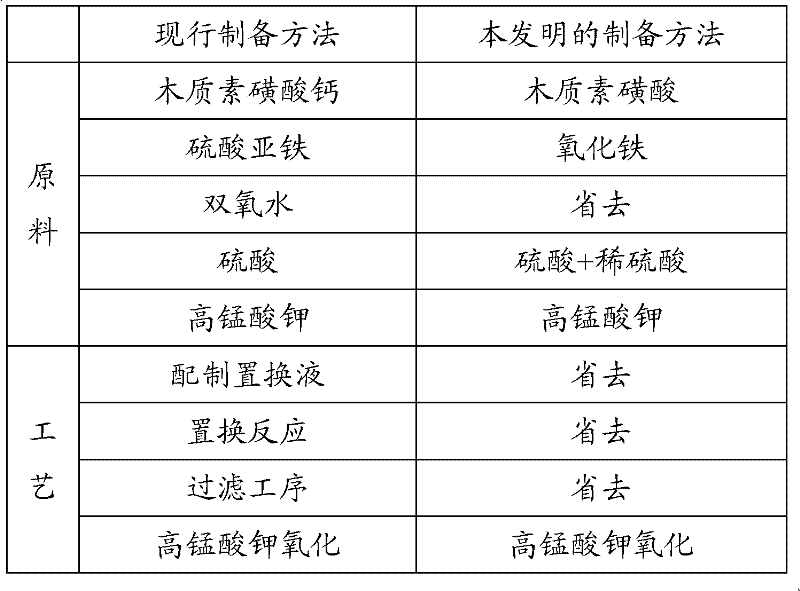

[0023] The preparation method of lignosulfonate ferric manganese salt provided by the invention comprises the following steps:

[0024] a) Mix lignosulfonic acid, iron oxide, dilute sulfuric acid and an oxidizing agent to obtain an iron lignosulfonate solution.

[0025] Lignosulfonic acid and iron oxide can be reacted by using the waste liquid containing lignosulfonic acid and the by-product iron oxide produced in the sulfurous acid pulping process, so that the pulping waste liquid can also be treated at the same time, and the lignin in it can be recycled . Acidic sulfurous acid pulping waste liquid is preferably pulp waste liquid with wood as raw material, such as sylvestris sylvestris, white pine and the like. In the process of pulping, sulfur dioxide produced by burning pyrite is absorbed to obtain calcium bisulfite, and then calcium bisulfite is used to sulfonate lignin to obtain calcium lignosulfonate, while under acidic conditions, lignosulfonate Calcium acid salt is c...

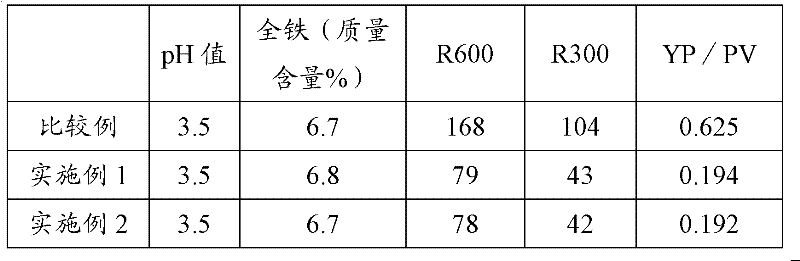

Embodiment 1

[0033] Sulfurous acid pulping wastewater is selected as the raw material, and in order to reduce the occupied area, the sulfurous acid pulping wastewater is concentrated to obtain a concentrated lignosulfonic acid solution with a mass percentage of 45%, a pH value of 1.8, and a calcium mass content of less than 3.0%.

[0034] Add 100 kilograms of ferric oxide in the reactor, 500 kilograms of dilute sulfuric acid (produced when sulfurous acid pulping wastewater is concentrated) that reclaims, dilute sulfuric acid mass concentration is 8%, add 20 kilograms of vitriol oils again, be warming up to 60 ℃ of reaction 1 Hours, all iron oxides reacted completely. Add 1000 kg of the above lignosulfonic acid solution, and react at 85°C-90°C for 30 minutes to obtain an iron lignosulfonate solution. The pH value of the solution is between 2.7 and the total iron content is 6.8%.

[0035] Then, a 15% solution containing 60 kg of potassium permanganate was added at 95°C. Insulate and react ...

Embodiment 2

[0037] The sulfurous acid pulping wastewater is concentrated to obtain a ligninsulfonic acid concentrated liquid with a mass percentage of 48%, a pH value of 1.5, and a calcium mass content of less than 3.0%.

[0038] Add 1800 kilograms of lignosulfonic acid solution, 100 kilograms of iron oxides, add 500 kilograms of reclaimed dilute sulfuric acid (dilute sulfuric acid mass concentration is 8%), 40 kilograms of concentrated sulfuric acid in reaction kettle, react 30 minutes under 90 ℃ of conditions, Obtain iron lignosulfonate solution. The pH value of the solution is between 2.5-3.0, and the mass content of total iron is 6.8%.

[0039] Then, a 15% solution containing 230 kg of potassium permanganate was added at 85°C. Incubate for 30 minutes. Lignosulfonate ferric manganese salt solution is obtained, and a granular product is obtained by spray drying. After testing, the moisture content of the product is less than 8.0%, the manganese content is 2.4%, the potassium content ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com