Preparation method of flexible CuInS2 solar battery based on thin copper substrate

A solar cell, flexible technology, applied in the direction of circuits, electrical components, climate sustainability, etc., can solve problems such as proportioning, difficult control of uniformity, poor bonding force between film and substrate, and difficulty in large-scale production. Lightweight, low equipment requirements, enhanced bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

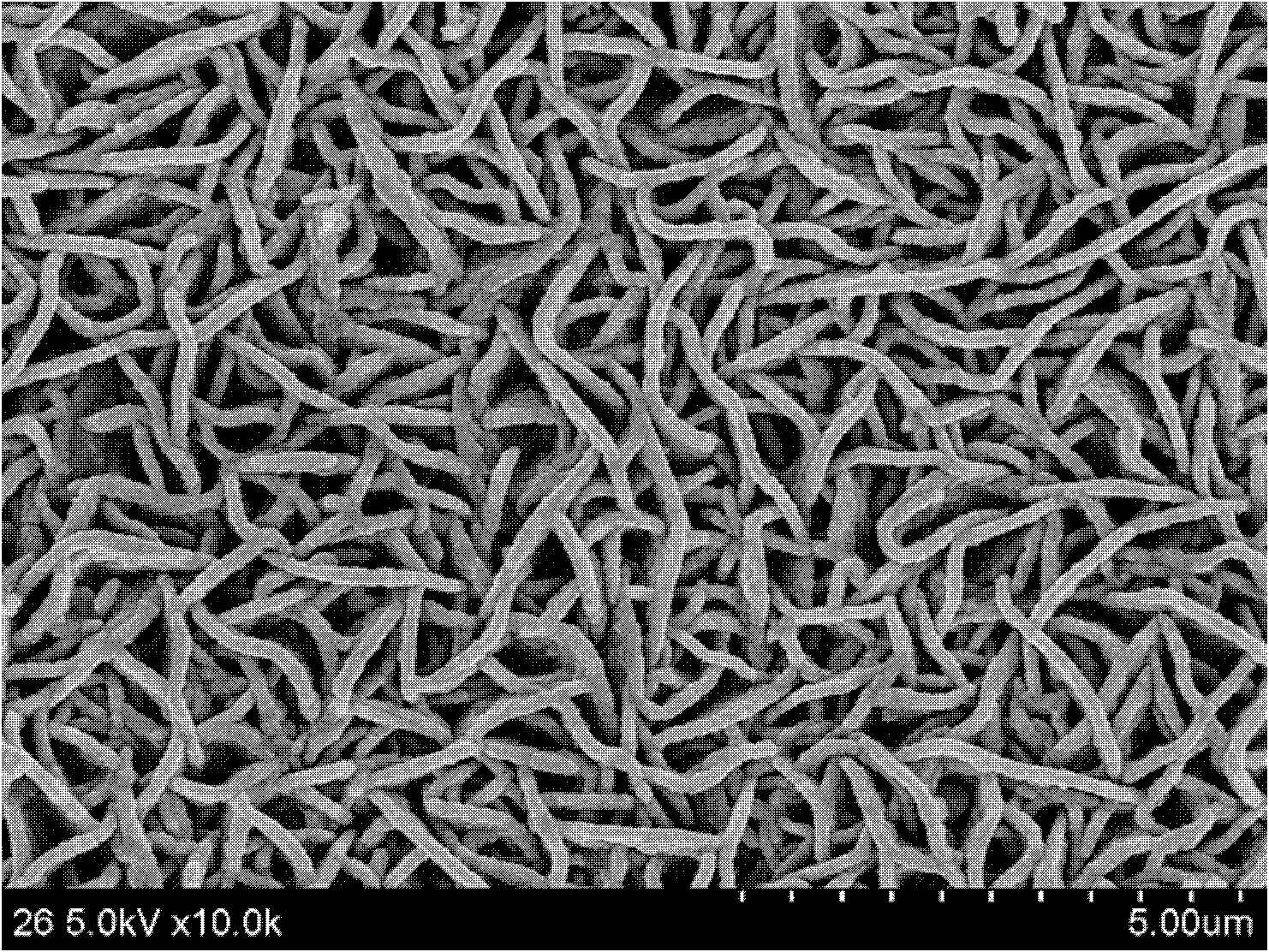

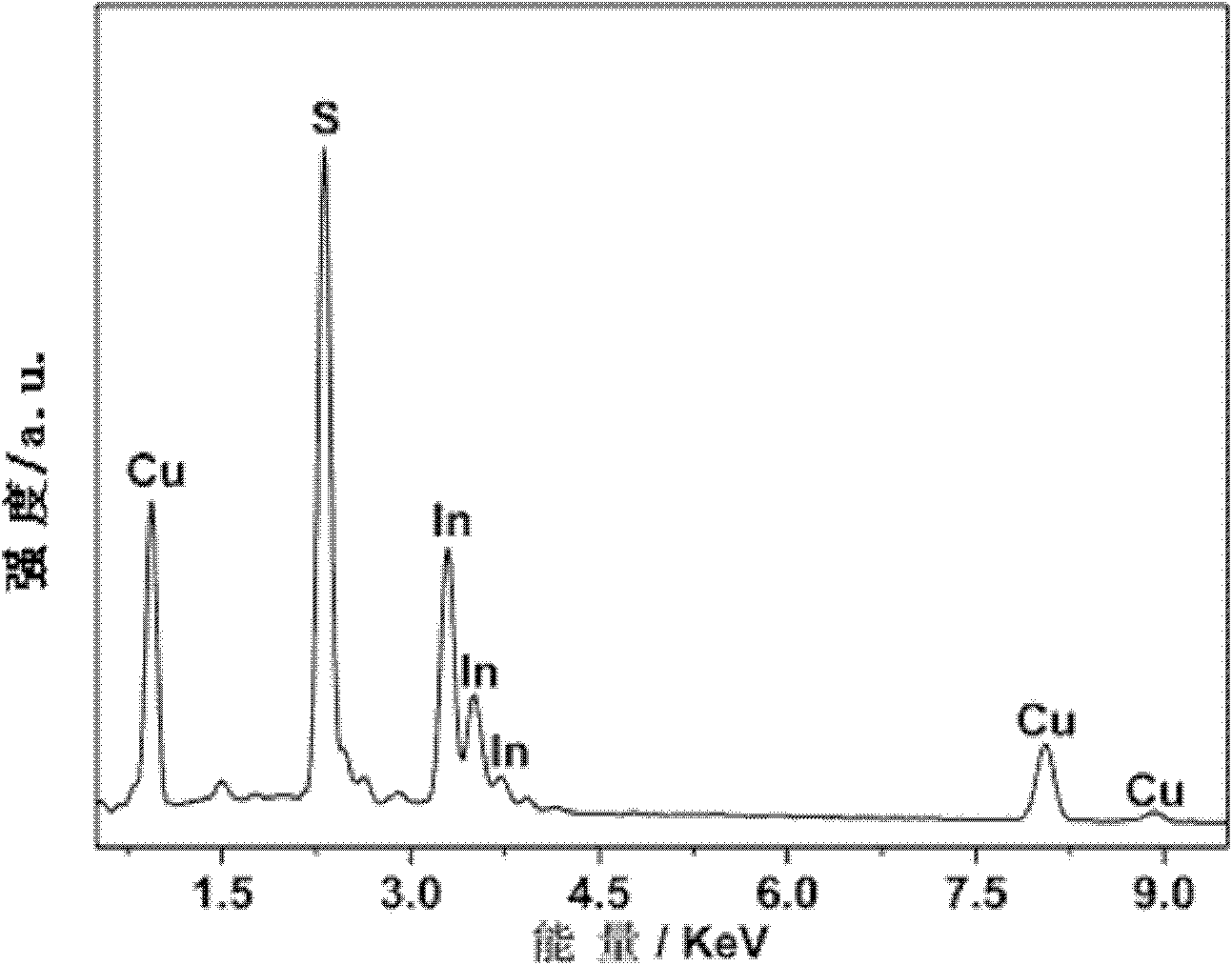

[0032] (1) Preparation of copper indium sulfur thin film material: weigh 0.25mmol CuSO 4 ·5H 2 O, 0.25mmol InCl 3 4H 2 O, dissolved in 15mL of ethylene glycol to obtain an ethylene glycol solution of copper indium salt; weigh 2mmol of thioacetamide, dissolve it in 10mL of ethylene glycol, dissolve it ultrasonically, and then add the above copper indium salt under stirring The ethylene glycol solution was transferred to a hydrothermal reaction kettle, a copper sheet was added, and the reaction was carried out at 160° C. for 18 hours. After the reaction, the CuInS 2 The copper piece was taken out and rinsed successively with distilled water and ethanol.

[0033](2) chemical bath deposition cadmium sulfide buffer layer: the 25wt% ammoniacal liquor of cadmium sulfate, thiourea, appropriate volume is made into solution, makes it alkaline, and makes the concentration of cadmium ion be controlled at 10 -3 ~10 -2 M, the concentration of sulfide ion is at 10 -2 ~10 -1 M, adjust...

Embodiment 2

[0035] (1) Preparation of Copper Indium Sulfur Film Material: A, put into 20% (quality) hydrochloric acid after polishing the ultra-thin flexible copper sheet surface of 2cm * 2cm with sandpaper and soak for 1 hour to remove the oxide on the copper sheet surface, use Wash the surface twice with deionized water, then ultrasonically wash the copper sheet in acetone for 10 minutes to remove organic matter on the surface, and dry it for later use. B. Weigh 0.5mmol CuSO 4 ·5H 2 O, 0.5mmol InCl 3 4H 2 O, placed in a conical flask, add 15mL of ethylene glycol, stir, and dissolve each substance. C. Weigh 3mmol of thioacetamide, dissolve it in 20mL of ethylene glycol, and ultrasonically dissolve it. Pour C into B under stirring conditions, continue to stir for half an hour, transfer to a hydrothermal reaction kettle, add the copper sheet treated in A, and react at 200°C for 24 hours. After the reaction, fishbone-like CuInS will grow 2 The copper piece was taken out and rinsed suc...

Embodiment 3

[0038] (1) Preparation of copper indium sulfur thin film material: A, put into 20% (quality) hydrochloric acid after polishing the surface of the ultra-thin flexible copper sheet of 2cm * 2cm with sandpaper and soak for 2 minutes to remove the oxide on the surface, use deionized Wash the surface with water for 3 times, then ultrasonically wash the copper sheet in ethanol for 20 minutes to remove the organic matter on the surface, and dry it for later use. B. Weigh 1mmol copper nitrate, 1mmol indium sulfate InCl 3 4H 2 O, placed in a conical flask, add 4mL of ethylene glycol, stir, and dissolve each substance. C. Weigh 2 mmol of thioacetamide, dissolve it in 10 mL of ethylene glycol, and ultrasonically dissolve it. Pour C into B under stirring conditions, continue to stir for half an hour, transfer to a hydrothermal reaction kettle, add the copper sheet treated in A, and react at 220°C for 24 hours. After the reaction, fishbone-like CuInS will grow 2 The copper piece was ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com