Stent type silk fibroin film insoluble in water, and preparation and application of stent type silk fibroin film

A silk fibroin and scaffold-type technology, which is applied in the field of insoluble silk fibroin membrane and its preparation, can solve the problems of uneven thickness of porous scaffold pore wall, high mechanics of silk fibroin scaffold and slow degradation rate, etc. Achieve the effect of facilitating mass production, simple preparation process and reducing foreign body sensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

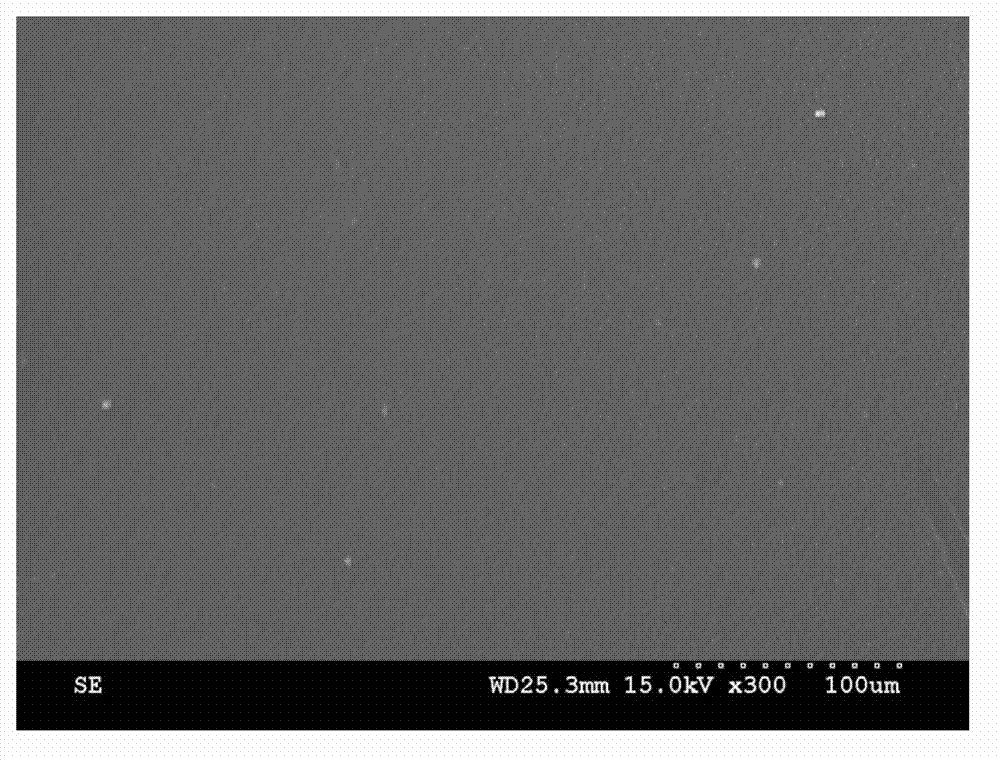

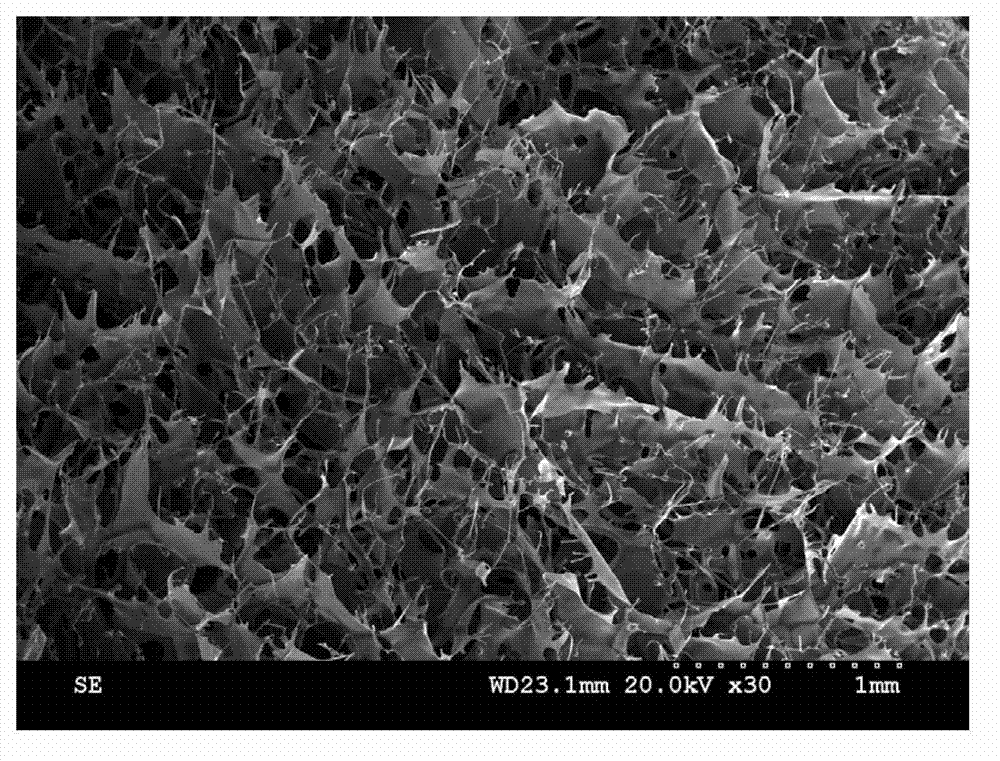

[0027] Example 1 (basement membrane 300 μm, scaffold layer 4000 μm)

[0028] (1) Preparation of silk fibroin solution: a) Degumming: Put 100g of silkworm silk (Zhejiang Huazhi Silk Co., Ltd., 5A grade) into 5L of 2M sodium carbonate aqueous solution, bathe in 98°C for 30min, wash with pure water, Repeat this process 3 times to remove the sericin and leave the silk fibroin. Dry the silk fibroin at 50°C to obtain 70g of dried silk fibroin for later use; b) dissolving: the above-mentioned dried silk fibroin The protein was dissolved in 9.3M lithium bromide (LiBr) aqueous solution at a mass volume ratio of 0.2:1, and the silk fibroin was fully dissolved in a water bath at 60°C for 90 minutes to obtain a mixed solution containing silk fibroin and a small amount of insoluble particles; c) Dialysis: the The mixed solution was dialyzed with a regenerated cellulose dialysis bag (molecular weight cut-off 4000 Daltons), dialyzed 12 times in 3 days with sterile pure water 10 times the vol...

Embodiment 2

[0033] Example 2 (basement membrane 200 μm, scaffold layer 1000 μm)

[0034] (1) Preparation of silk fibroin solution: a) Degumming: Put 100g of silkworm silk (Zhejiang Huazhi Silk Co., Ltd., 5A grade) into 5L of 2M sodium carbonate aqueous solution, bathe in 98°C for 30min, and wash with deionized water , this process was repeated 3 times, the sericin was removed, and the silk fibroin was left, and the silk fibroin was dried at 50°C to obtain 70g of dried silk fibroin for later use; b) dissolving: the above-mentioned dried silk The fibroin is dissolved in 9.3M lithium bromide (LiBr) aqueous solution at a mass volume ratio of 0.2:1, and the silk fibroin is fully dissolved in a 60°C water bath for 90 minutes to obtain a mixed solution containing silk fibroin and a small amount of insoluble particles; c) Dialysis: The above mixed solution was dialyzed with a regenerated cellulose dialysis bag (molecular weight cut-off 8000 Daltons), dialyzed 12 times with sterile deionized water...

Embodiment 3

[0039] Example 3 (basement membrane 100 μm, scaffold layer 2000 μm)

[0040] (1) Preparation of silk fibroin solution: a) Degumming: Put 100g of silkworm silk (Zhejiang Huazhi Silk Co., Ltd., 5A grade) into 5L of 2M sodium carbonate aqueous solution, bathe in 98°C for 30min, and wash with deionized water , this process was repeated 3 times to remove the sericin and leave the silk fibroin, and dry the silk fibroin at 50°C to obtain 70g of dried silk fibroin for later use; b) dissolving: dissolve the silk fibroin by mass Dissolve in 9.3M lithium bromide (LiBr) aqueous solution at a volume ratio of 0.20:1, bathe in water at 60°C for 90 minutes until the silk fibroin is fully dissolved, and obtain a mixed solution containing silk fibroin and a small amount of insoluble particles; c) Dialysis: Dilute the mixed solution with The regenerated cellulose dialysis bag (molecular weight cut-off 2000 Dalton) was dialyzed, and the sterile deionized water of 10 times the volume of the mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com