Non-disperse infrared multi-component flue gas analyzer

A non-dispersive infrared and flue gas analyzer technology, which is applied in the direction of material analysis, material analysis by electromagnetic means, material analysis by optical means, etc., can solve the problems of large measurement error and complex structure of monitoring device, and achieve the deduction of interference , expand the dynamic measurement range, increase the effect of absorption optical path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

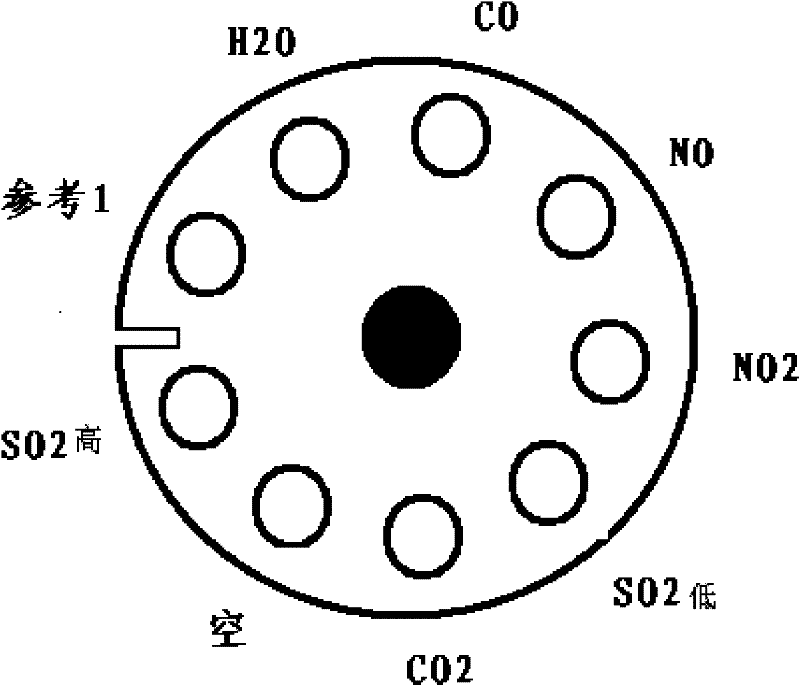

[0033] Such as figure 1 shown. A non-dispersive infrared multi-component flue gas analyzer includes an infrared light source, an optical filter wheel, a multiple reflection pool, a gas path system and a data analysis system. The light beam generated by the infrared light source enters the multiple reflection pool through the optical filter device, and enters the infrared detector after multiple reflections. The solenoid valve controls the flow direction of the sampled gas, and the flow controller keeps the flow rate of the sampled gas constant. The data sampling and analysis system is divided into three parts: pre-amplification, A / D conversion, and analysis and processing.

[0034] Such as figure 2 shown. The filter installation sequence is: blank aperture, CO 2 , SO 2 (low), NO 2 , NO, CO, H 2 O, reference 1, SO 2 (high).

[0035] The invention is a portable non-dispersive infrared multi-component flue gas on-line analyzer. A light source with black-body radiation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com