Nano environment-friendly reinforced floor and manufacturing method

A technology for strengthening flooring and manufacturing methods, which is applied in the direction of manufacturing tools, floors, wood processing appliances, etc. It can solve the problems of poor wear resistance, deformation and softening, decomposition, and non-waterproof, etc., and achieve the effect of excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

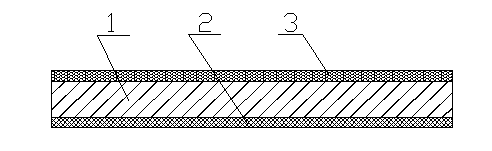

[0009] Embodiment 1: with reference to attached figure 1 . A nano-type environmentally friendly reinforced floor, which includes a base layer 1 and a bottom layer 3, the base layer 1 is a density board, the bottom layer 3 is a waterproof membrane layer and is composited on one side of the base layer 1, and the other side of the base layer 1 is provided with a nano layer 2. The nano-layer 2 is a pure nano-layer or a nano-composite layer. The nanocomposite layer is composed of non-nanofibers and nanofibers. The non-nanofibers refer to wood pulp fibers. The non-nanofibers refer to bamboo pulp fibers.

Embodiment 2

[0010] Embodiment 2: On the basis of Embodiment 1, the nano-layer is a nano-fiber layer (nano-paper) made of nano-fibers.

Embodiment 3

[0011] Embodiment 3: On the basis of Embodiment 1, the nano-composite layer is composed of wood pulp fibers and nano-fibers to form a nano-wood fiber composite layer 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com