Glass fiber reinforced polypropylene material and preparation method thereof

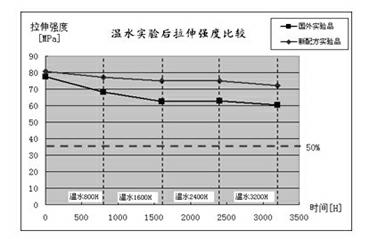

A technology of polypropylene material and copolymerized polypropylene, which is applied in the field of glass fiber reinforced polypropylene material and its preparation, can solve the gaps in mechanical properties, hydrolysis resistance and thermal oxidation resistance, imperfect material formula and processing technology, mechanical properties There are still problems to be improved to achieve the effect of excellent hydrolysis resistance, easy control of glass fiber content, and excellent hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] 40 parts of copolymerized polypropylene, 40 parts of homopolypropylene, 5 parts of maleic anhydride grafted polypropylene, 0.5 parts of antioxidant 330, 0.5 parts of antioxidant 1035, 1.5 parts of antioxidant DSTP, 0.5 parts of antioxidant 618 1 part, light stabilizer (bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate) 1 part and lubricant EBS 1 part, add to the high mixer in turn and mix well After 3-5 minutes, put the mixture into the hopper and use a twin-screw extruder to mix and melt it, and then mix 10 parts of the glass fiber whose surface has been treated with a silane coupling agent in the twin-screw extruder, and melt-extrude Pull out the strip, cool it with water, dry the moisture on the surface of the strip, and then pelletize. The screw diameter of the twin-screw extruder is 20-65mm, and the length-to-diameter ratio of the screw is 40:1. The melting temperature is set as follows: 1 Zone 180°C, Zone 2 190°C, Zone 3 200°C, Zone 4 210°C, Zone 5 220°C, Melt Tempe...

Embodiment 2

[0079] 30 parts of copolymerized polypropylene, 35 parts of homopolypropylene, 5 parts of polypropylene grafted with glycidyl acrylate, 1 part of antioxidant 330, 1 part of antioxidant 3114, 1 part of antioxidant 1035, antioxidant 300 1 part, antioxidant 626 0.5 part, antioxidant 618 1 part, antioxidant 168 0.5 part, poly{[6-[(1,1,3,3-tetramethylbutyl)amino]]- 1,3,5-Triazine-2,4-bis[(2,2,6,6,-tetramethyl-piperidinyl)imino]-1,6-hexadiene[(2,2, 6,6-tetramethyl-4-piperidinyl)imino]} 1 part, polysuccinic acid (4-hydroxy-2,2,6,6-tetramethyl-1-piperidinyl) ester 1 part Add 2 parts of polyethylene wax and polyethylene wax into the high mixer in turn, mix thoroughly for 3-5 minutes, then put the mixture into the hopper and use a twin-screw extruder to mix and melt, and then pass through the same surface in the twin-screw extruder Blend 20 parts of glass fiber treated with silane coupling agent, melt and extrude the strands, cool with water, dry the moisture on the surface of the stra...

Embodiment 3

[0097] Add 50 parts of copolymerized polypropylene, 30 parts of homopolypropylene, and 5 parts of glycidyl acrylate grafted polypropylene into the high mixer in sequence, and mix thoroughly for 3-5 minutes, then put the mixture into the hopper for The twin-screw extruder is mixed and melted, and then blended with 15 parts of glass fibers whose surface has been treated with a silane coupling agent in the twin-screw extruder, and the strands are melted and extruded, cooled by water, and the moisture on the surface of the strands is blown dry. , and then pelletized. The screw diameter of the twin-screw extruder is 20-65mm, and the length-to-diameter ratio of the screw is 40:1. Zone 200°C, zone 5 210°C, melt temperature 205°C, head 195°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Screw diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com