N-type solar battery prepared by film masking process of one multi-purpose film and preparation method of N-type solar battery

A solar cell and mask technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of complex process and high cost of n-type solar cells, and achieve high photoelectric conversion efficiency, low cost, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

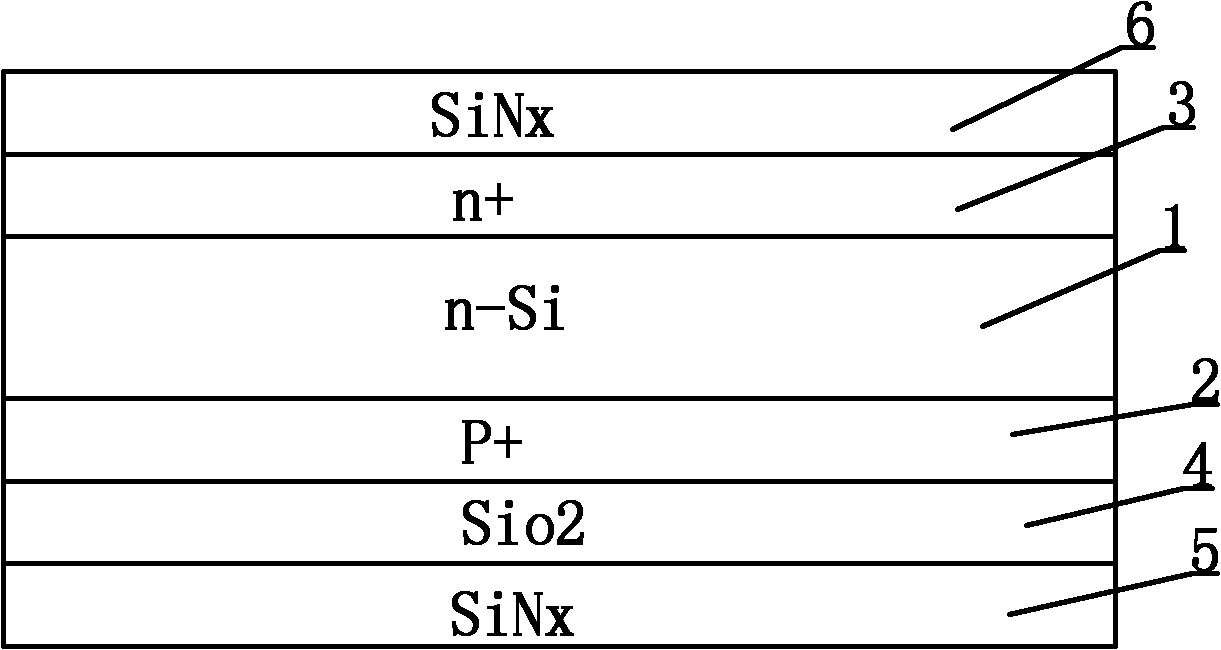

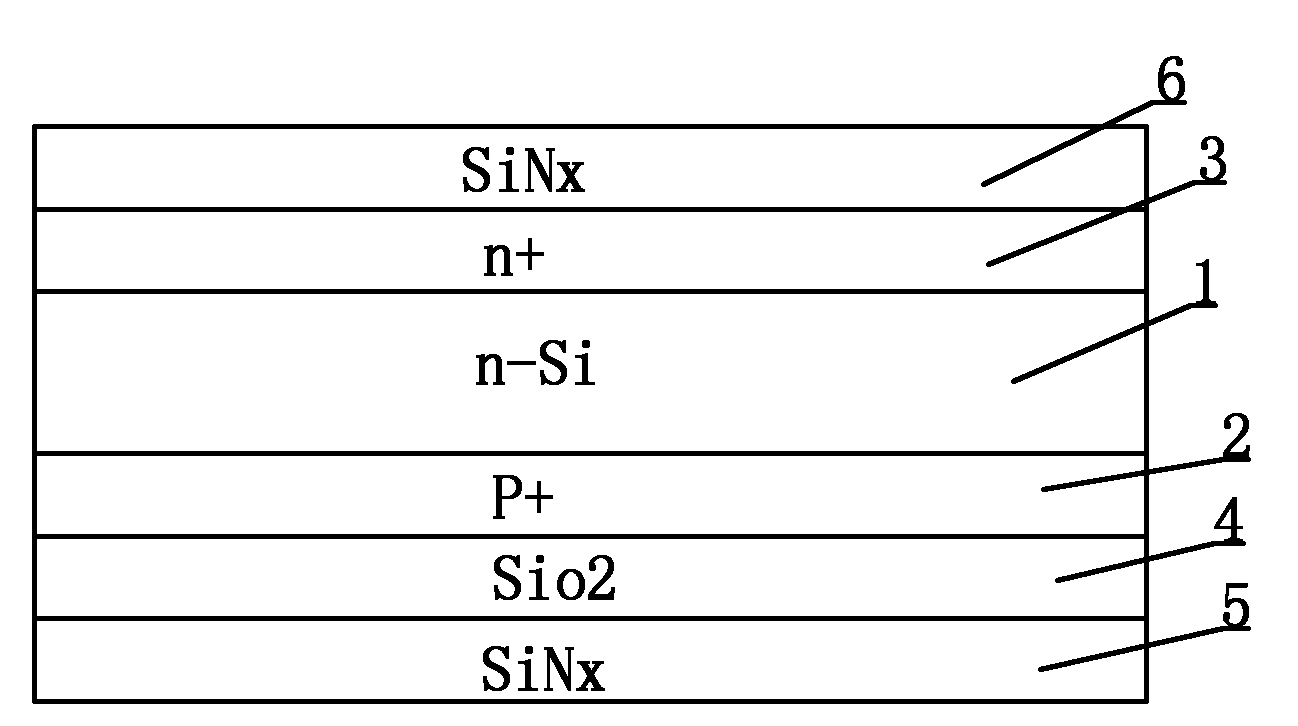

[0026] Example 1: An n-type Czochralski monocrystalline silicon wafer was selected, with a crystal plane of (100) and a doping concentration of 6Ωcm.

[0027] 1. The silicon wafer undergoes conventional surface cleaning and normal pyramid surface texture treatment;

[0028] 2. BBr3 liquid boron diffusion source to prepare P-type emitter junction 2, the diffusion temperature is 930℃, the time is 50min, and the sheet resistance is 60ohm / Sq;

[0029] 3. Use RENA's post-cleaning machine to etch away the P-type emitter junction on the back and remove the BSG at the same time;

[0030] 4. Use thermal oxidation to grow SiO2 film 4 as a mask layer with a thickness of 300nm;

[0031] 5. Etch the SiO2 film on the non-emitter surface with corrosive slurry;

[0032] 6. The surface field 3 before preparation of POCl3 liquid phosphorus diffusion source, the diffusion temperature is 850℃, the time is 40min, and the sheet resistance is 40ohm / Sq;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com