Graphene/copper nanowire composite electric-conducting material and preparation method thereof

A copper nanowire and composite conductive technology, which is applied in the direction of cable/conductor manufacturing, metal/alloy conductor, carbon-silicon compound conductor, etc., can solve the problems of application limitation, complicated preparation process, and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] The specific preparation steps of the composite conductive material and preparation method of a kind of graphene / copper nanowire of the present invention are as follows:

[0075] (1) Use copper, cobalt, nickel, ruthenium metals with high specific surface area (such as metal foam copper, foam cobalt, nickel foam) and inert support copper, cobalt, nickel and ZnS fine particles as catalysts, put them into chemical vapor deposition The reaction chamber is sealed, checked for air tightness, exhausted under a protective atmosphere, and then heated to a reaction temperature of 600-1000°C. After a constant temperature of 0-60min, carbon source, hydrogen and protective gas are introduced, and the gas flow rate is 1-1000sccm. The reaction time is 1-60min. After the reaction is completed, the cooling rate is controlled to be 10-300°C / min, and cooled to room temperature. Put the prepared product into the etching solution, heat and stir to remove the catalyst and support, then vacuu...

Embodiment 1

[0129] (1) Weigh 1.5g MgO and 0.3g cupric chloride into a beaker filled with 20ml ethanol, stir vigorously for 4 hours, dry in vacuum, reduce in a hydrogen-argon mixed atmosphere at 500°C for 6 hours, take it out after natural cooling, and put it into a CVD reaction furnace 100 sccm hydrogen gas and 100 sccm argon gas were introduced, and after 60 minutes, heating was started to 1000°C. After 30 minutes of constant temperature, 30 sccm methane was introduced, and the reaction time was 30 minutes.

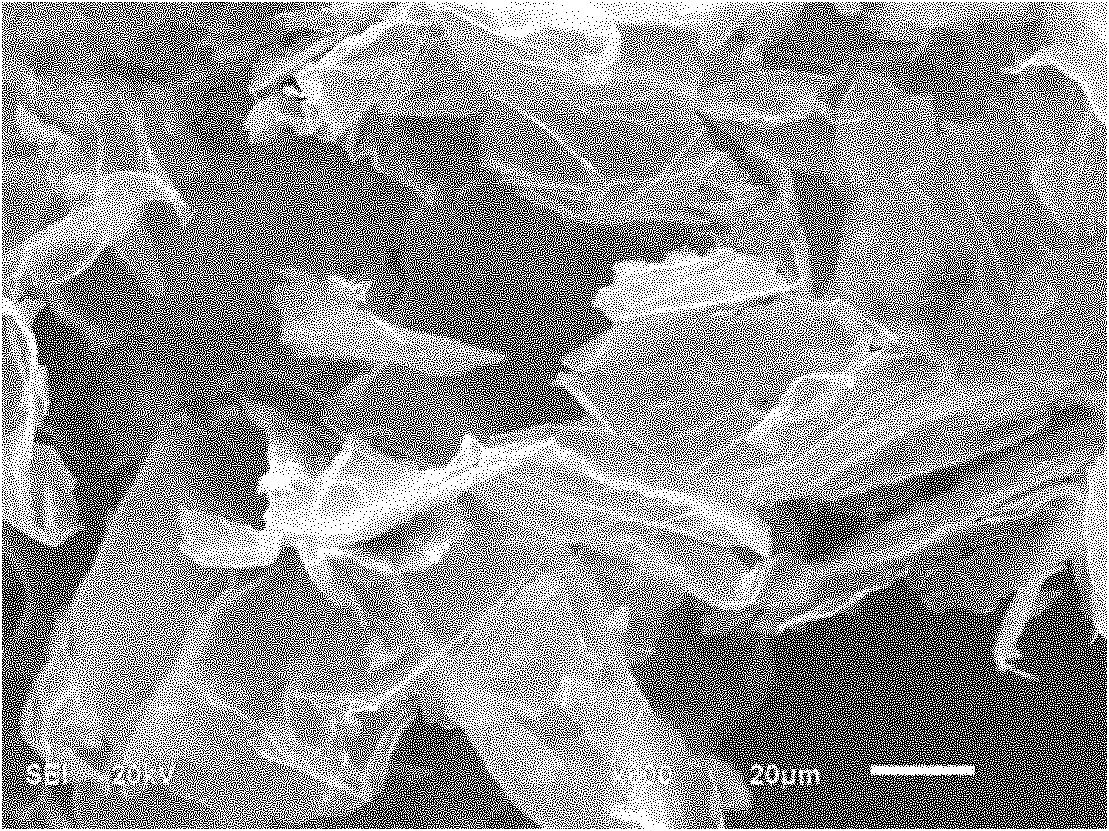

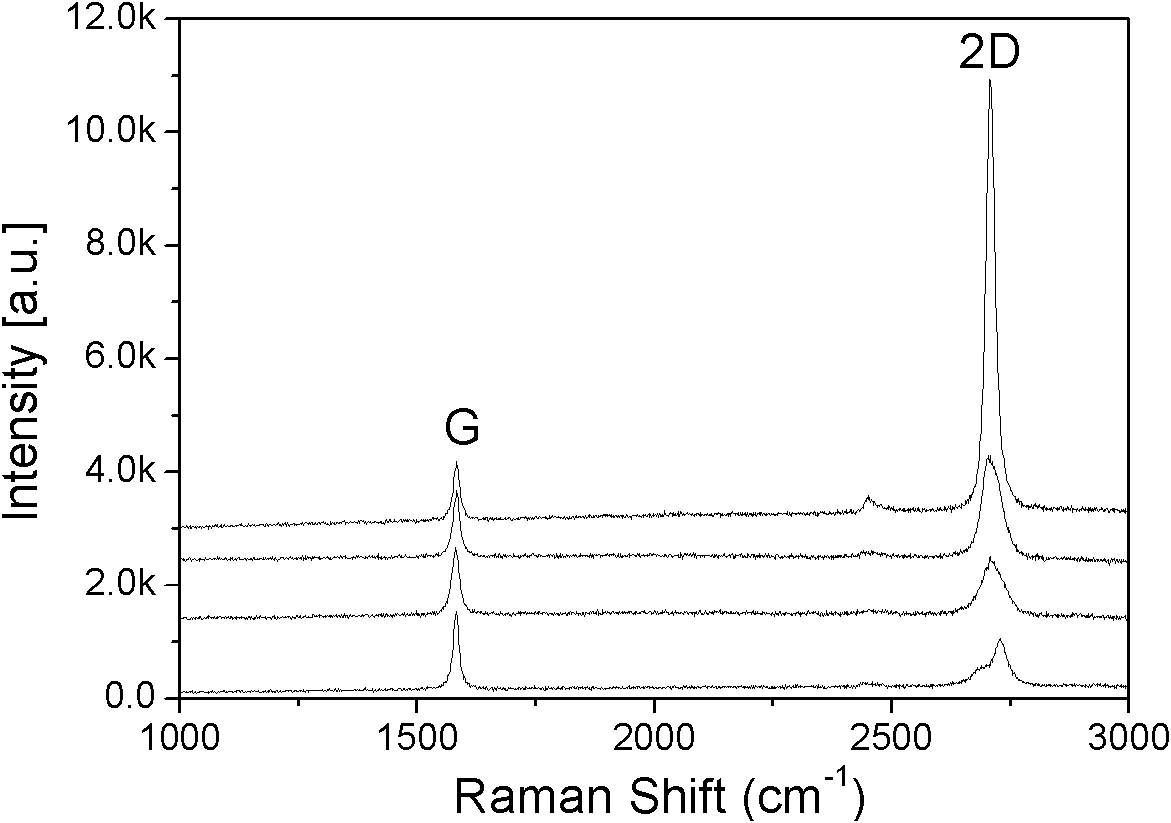

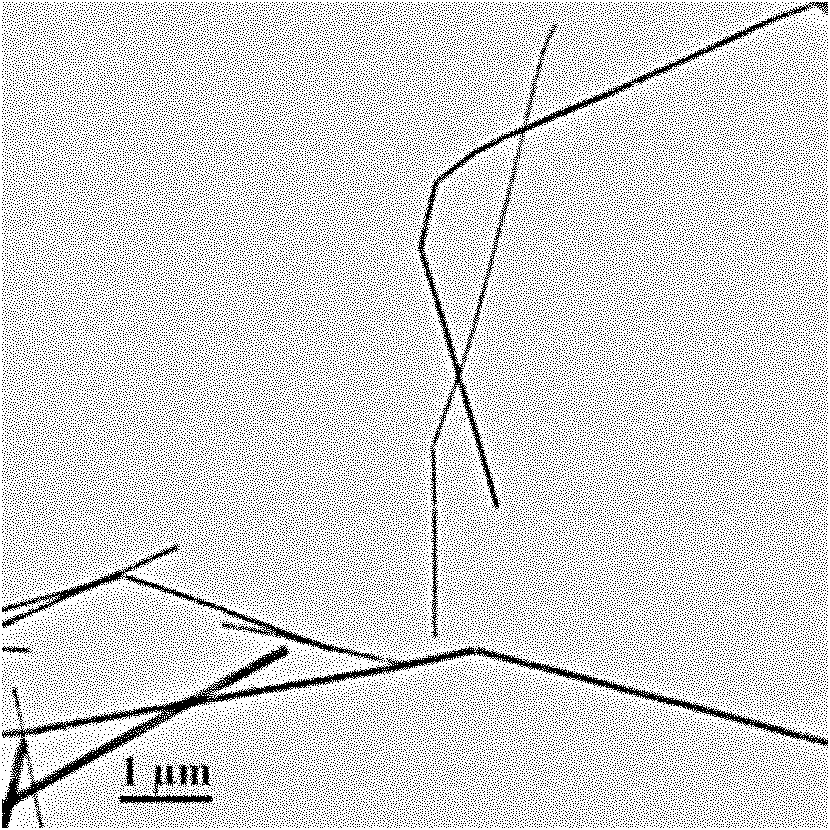

[0130] (2) Put the product prepared in step (1) into 100ml 1M hydrochloric acid and 1M FeCl 3 Stir in the solution for 4h to remove MgO and metal copper particles, then vacuum filter and wash to neutrality with deionized water, the product scanning electron micrograph and Raman spectrum are as follows: figure 1 and 2 As shown, it is indicated that graphene is 1-10 atomic layers.

[0131] (3) Weigh 1mmol of copper sulfate and 2mmol of octadecylamine into 100ml of deionized water, s...

Embodiment 2

[0134] The preparation method is basically the same as Example 1, and the difference is: in the step (1), adopting the nickel foam through ethanol, acetone and isopropanol ultrasonic cleaning is a catalyst, by 5sccm ethylene, 100sccm nitrogen, and the reaction times 10min; step (2 ), using concentrated hydrochloric acid to remove foamed nickel; in step (3), using 2mmol copper chloride and 2mmol tetradecylamine as reactants, the reaction temperature is 180°C, the average diameter of the prepared copper nanowires is 40nm, and the length is tens of microns In step (4), take by weighing 0.1g graphene and 5mg copper nano wire, be dispersed in the NMP solution of PVDF, handle 80min at 350 ℃ under 5% hydrogen-argon mixed atmosphere, the volume resistivity of the composite conductive material that obtains 9.15×10 -4 Ω cm, the cell efficiency is 11.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com