Method for producing high-density recombined wood

A production method and high-density technology, applied in wood compression, veneer manufacturing, wood processing appliances, etc., can solve problems such as waste, and achieve the effects of improved insect-proof performance, less cracking, and unique texture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

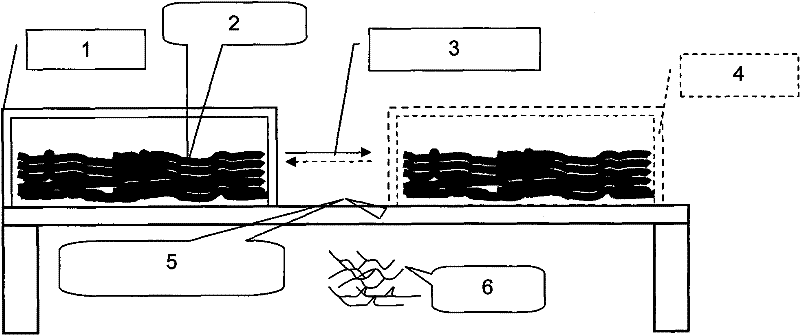

Method used

Image

Examples

Embodiment 1

[0067] Choose 1.0-1.5mm thick rotary-cut technical wood scraps, place them in an autoclave, and feed them with high-temperature steam for 1-1.5 hours. The steam pressure is 3Mpa, and the temperature is 135-140°C.

[0068] After leaving the kettle, shake it while it is hot, and let it stand for 1 to 7 days to reduce the moisture content of the veneer to below 20%, so that the wood can absorb glue better.

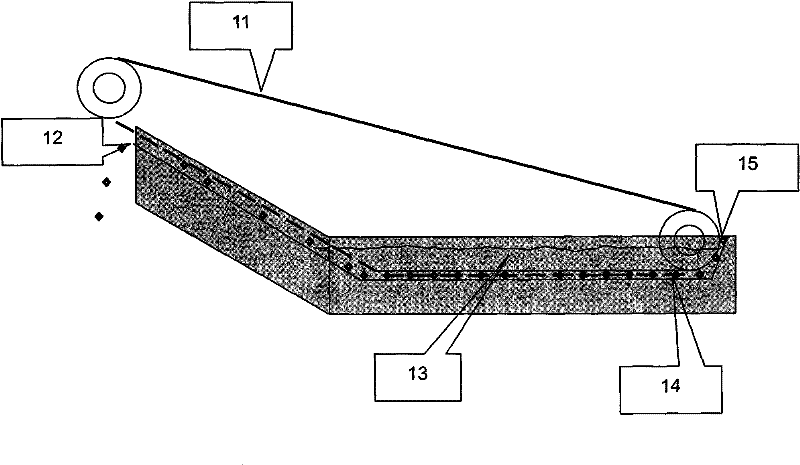

[0069] On the chain sizing equipment, apply glue to the veneer, use phenolic resin solution, and soak the glue for 1 minute, so that the veneer can fully absorb the glue.

[0070] Hang the veneer after dipping on the conveyor frame, and drain the excess glue on the veneer.

[0071] Dry at a temperature of 55°C to make the moisture content 10-20%.

[0072] Bundle the veneer into a uniform handle with a length of 1.93 meters and a weight of 3-10Kg.

[0073] Put the handle in the balance health room for 3 to 15 days. The temperature in the balanced health care room is control...

Embodiment 2

[0077] Choose miscellaneous wood poles with a diameter of 3-8cm, put some miscellaneous wood poles into the planing equipment, and plan them into thin wood chips with a thickness of 0.5-1.5mm.

[0078] Cook with 2% hydrogen peroxide for 1.5 hours.

[0079] Treat it with high-temperature steam for 2.5 hours, the steam pressure is 2Mpa, and the temperature is 115-125°C.

[0080] It is dipped on the chain sizing equipment, using phenolic resin solution, and the dipping time is 1 minute, so that the veneer can fully absorb the glue.

[0081] Put the dipped veneer into the frame and drain off the excess glue. The time for draining the glue is 0.5-2 hours.

[0082] After gluing, dry at a temperature of 50°C, and dry the veneer after gluing to make the water content 10-20%.

[0083] Place the dried veneer in a balanced health care room for 3 to 15 days. The temperature in the balanced health care room is controlled at 30°C and the humidity is controlled at 65%, so that the moisture...

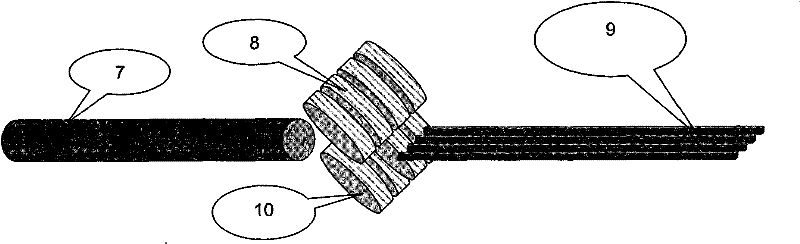

Embodiment 3

[0087] Choose 1.0-1.5mm thick rotary-cut technical wood scraps, place them in an autoclave, and feed them with high-temperature steam for 1-1.5 hours. The steam pressure is 3Mpa, and the temperature is 135-140°C.

[0088] After leaving the kettle, the original adhesive of the technological wood will fail, and the veneer will be shaken off while it is hot.

[0089] Weave thin wood chips into rope with a rope braiding machine.

[0090] It is dipped on the chain sizing equipment, using phenolic resin solution, and the dipping time is 1 minute, so that the veneer rope can fully absorb glue.

[0091] Drain the excess glue on the thin wood rope after dipping, and the time for draining the glue is 0.5 to 2 hours.

[0092] After gluing, dry at a temperature of 58° C., and dry the veneer after gluing to make the water content 10-20%.

[0093] Place the dried veneer ropes in a balanced health care room for 3 to 15 days. The temperature in the balance health care room is controlled at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com