Multi-station machine vision imaging detection method and system based on graphics processor

A graphics processor and machine vision technology, applied in closed-circuit television systems, processor architecture/configuration, liquid level indicators for physical variable measurement, etc., can solve the problem of increasing the size and cost of machine vision detection equipment, and the detection time of a single computer Difficult to control, difficult to achieve stability, reliable detection and other issues, to achieve the effect of improving system stability and reliability, reducing system complexity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

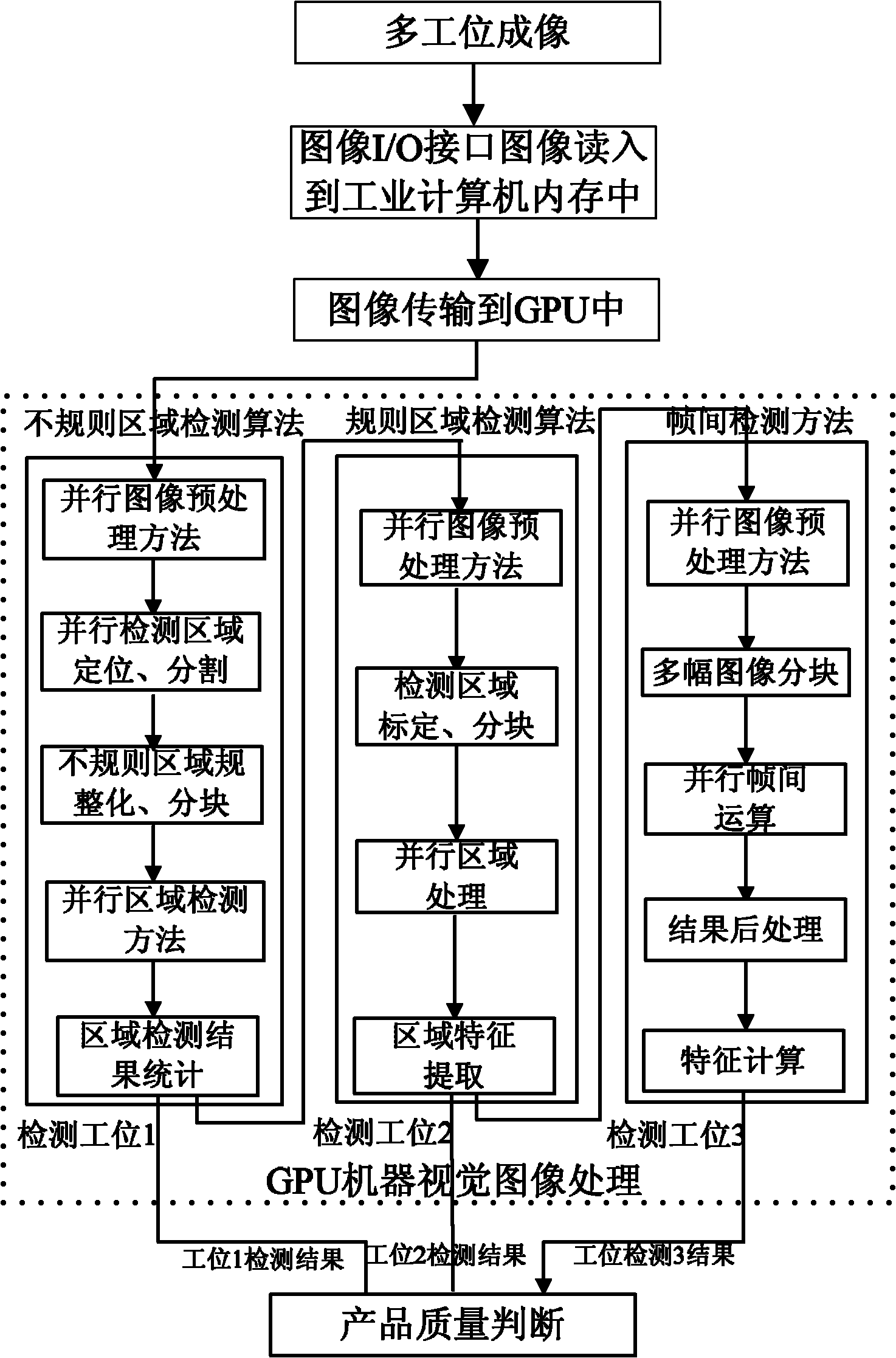

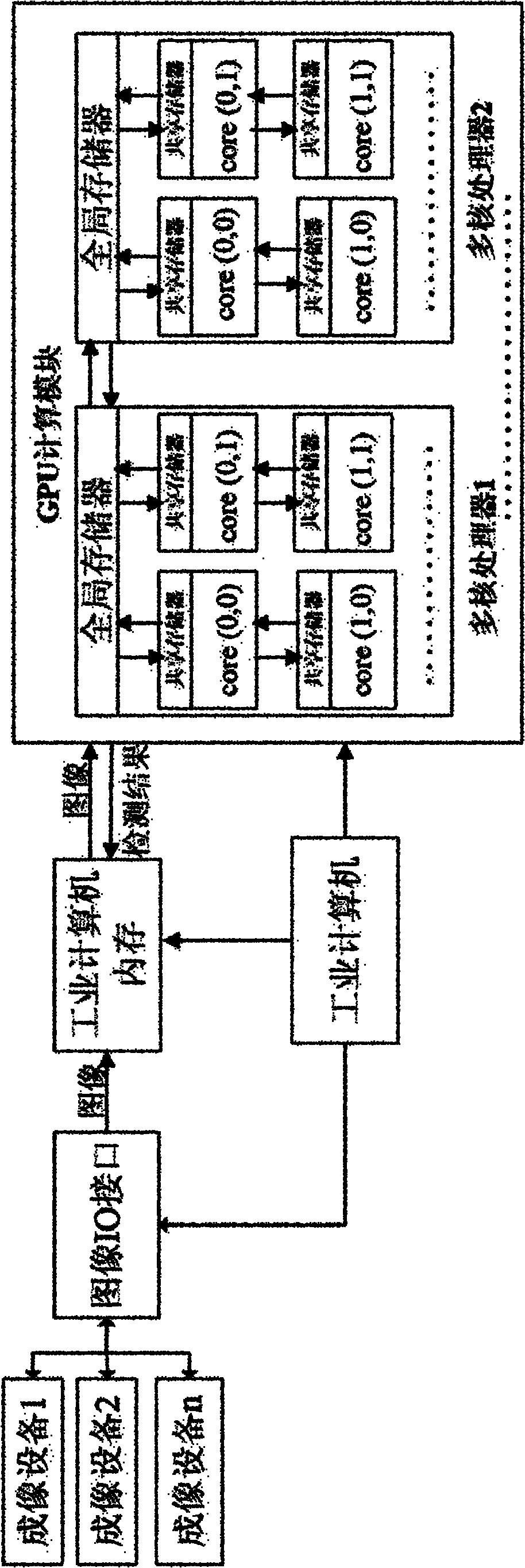

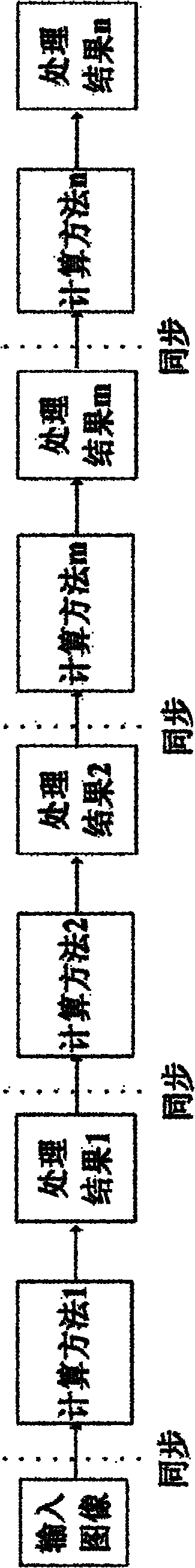

[0045] Graphics Processing Unit (GPU), referred to as GPU, is a processor for large-scale parallel processing of graphics and images. It is usually used as a slave device of a general-purpose processor to process and display graphics and images in real time. In the GPU, there are multiple multi-core processors, and each multi-core processor contains multiple processing units. Each processing unit can run multiple threads at the same time. This large-scale parallel structure is very suitable for real-time image processing, and has Hundreds of gigabytes per second of communication bandwidth, hundreds of billions of computing power. The present invention adds several GPU modules on the basis of the traditional machine vision inspection equipment, utilizes the large-scale graphics and image processing capability of the GPU to perform para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com