Method for preparing thin film of high-temperature superconductive coating conductor BaZrO3 buffer layer

A technology of coated conductors and high-temperature superconductivity, which is applied in the manufacture/processing of superconductor devices, chemical instruments and methods, inorganic chemistry, etc., and can solve problems affecting the superconducting performance of ReBCO

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

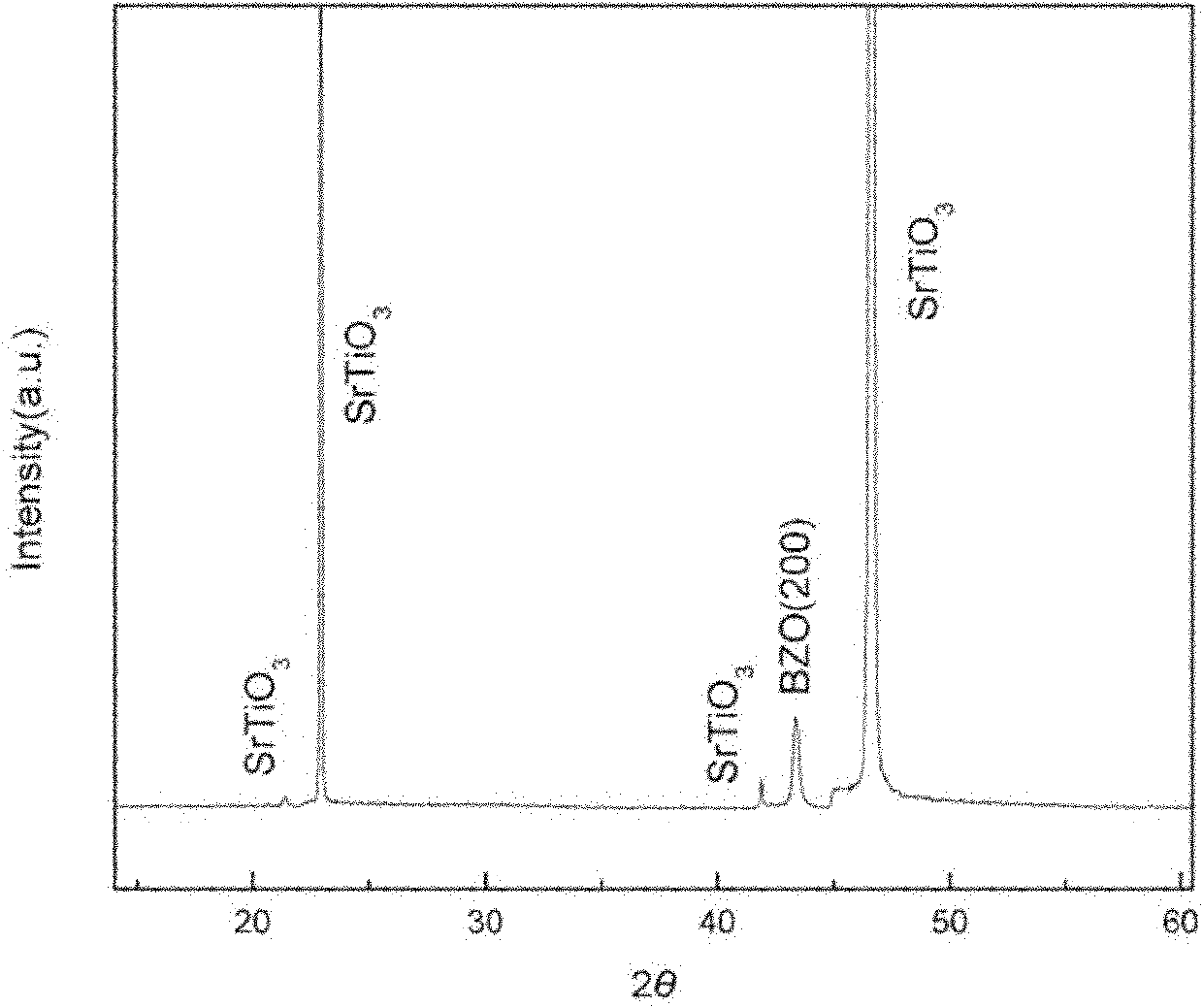

[0028] The first specific embodiment of the present invention is a kind of high temperature superconducting coating conductor BaZrO 3 The method for buffer layer thin film, its step is:

[0029] a, preparation of anhydrous solution: barium acetate and zirconium acetylacetonate are equal to the ratio of 1: 1 by the ion number ratio of barium: zirconium, dissolve in propionic acid, ultrasonic makes solution uniform, forms anhydrous solution;

[0030] b. Colloid preparation: Add polyvinyl butyral (PVB) to the anhydrous solution in step a for ultrasonic dissolution to form a viscous colloid. The addition of polyvinyl butyral (PVB) accounts for 5% of the total mass of the colloid.

[0031] c. Colloid coating and drying: Coat the colloid prepared in step b on the substrate, and then dry at 150°C. The specific method of coating the colloid on the substrate of the coated conductor is as follows: drop the colloid on the substrate and rotate it with a glue leveler so that the colloid ...

Embodiment 2

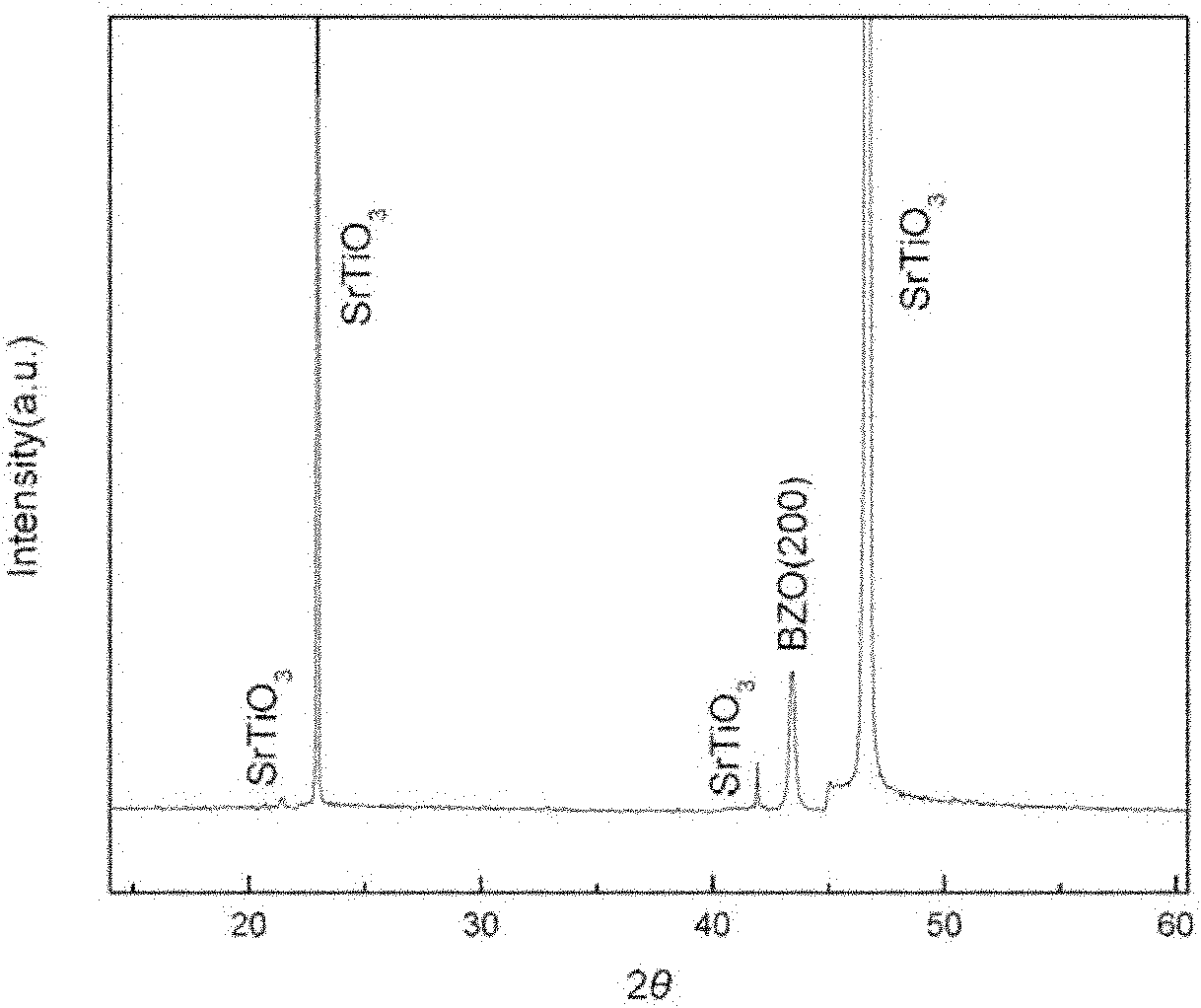

[0037] The preparation method of this example consists of the following steps in turn:

[0038] a, preparation of anhydrous solution: barium acetate and zirconium acetylacetonate are equal to the ratio of 1: 1 by the ion number ratio of barium: zirconium, dissolve in propionic acid, ultrasonic makes solution uniform, forms anhydrous solution;

[0039]b. Colloid preparation: Add polyvinyl butyral (PVB) to the anhydrous solution in step a for ultrasonic dissolution to form a viscous colloid. The addition of polyvinyl butyral (PVB) accounts for 4% of the total mass of the colloid.

[0040] c. Colloid coating and drying: Coat the colloid prepared in step b on the substrate, and then dry at 100°C. The specific method of coating the colloid on the substrate of the coated conductor is as follows: drop the colloid on the substrate and rotate it with a glue leveler so that the colloid is evenly coated on the substrate.

[0041] d. Thermal decomposition treatment: place the colloid-co...

Embodiment 3

[0046] The preparation method of this example consists of the following steps in turn:

[0047] a, preparation of anhydrous solution: barium acetate and zirconium acetylacetonate are equal to the ratio of 1: 1 by the ion number ratio of barium: zirconium, dissolve in propionic acid, ultrasonic makes solution uniform, forms anhydrous solution;

[0048] b. Colloid preparation: Add polyvinyl butyral (PVB) to the anhydrous solution in step a for ultrasonic dissolution to form a viscous colloid. The amount of polyvinyl butyral (PVB) added accounts for 3% of the total mass of the colloid.

[0049] c. Colloid coating and drying: Coat the colloid prepared in step b on the substrate, and then dry at 200°C.

[0050] d. Thermal decomposition treatment: place the colloid-coated substrate in a sintering furnace, and feed argon gas into the sintering furnace to raise the furnace temperature to 170°C at a rate of 1°C / min, and then increase the temperature at a rate of 0.5°C / min. The speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com