Solvent lignin-modified epoxy resin curing agent and preparation method thereof

A technology of epoxy resin curing and lignin, applied in epoxy resin coatings, coatings and other directions, can solve the problems of water resistance, low flexibility, uncritical ratio, high price, low manufacturing cost, low carbon development Economical, high-purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

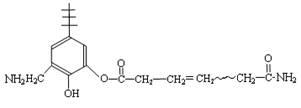

Image

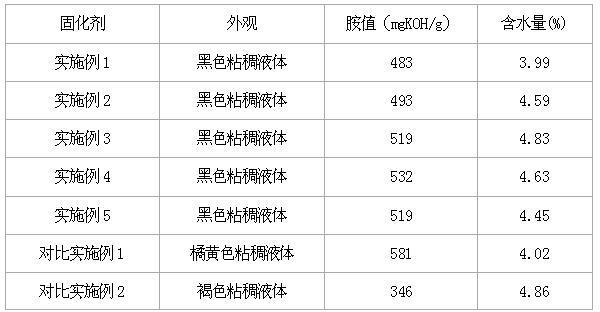

Examples

Embodiment 1

[0041] Example 1. Enzymatic hydrolysis of lignin directly reacts with phenol, aldehyde and amine to prepare epoxy resin curing agent through Mannich reaction

[0042] Add 10g of enzymatic lignin and 40g of phenol into a three-necked flask with a reflux condenser and stirrer, fill it with nitrogen and heat to dissolve it, heat up and stir. After it is completely dissolved, add 0.2g of concentrated sulfuric acid as a catalyst and continue to heat up to 85 ℃, react for 45min, then lower the temperature to 60℃, add 30g triethylenetetramine and 20g formaldehyde respectively, after the dripping is completed, heat and reflux for 1.5h, then vacuum dehydration, until 72g viscous phenalkamine epoxy is obtained Resin curing agent.

Embodiment 2

[0043] Example 2. Demethylation of enzymatic lignin, and Mannich reaction with phenol, aldehyde and amine to prepare epoxy resin curing agent

[0044] Install a stirrer, reflux condenser and thermometer on a 1000ml three-necked round-bottom flask, and first digest 80g of enzyme

[0045] Add lignin to a three-neck round-bottom flask, then add 3% (weight ratio) sodium hydroxide solution, heat up and stir until the lignin is dissolved, then add 3 g of sulfur, continue to slowly heat up to a certain temperature, and stir at constant temperature for a period of time Time, then quickly cool to room temperature, add water to dilute, acidify with sulfuric acid to pH=3, and then extract with ethyl acetate. After centrifugation, separate the aqueous phase and the organic phase. Separate the organic phase and evaporate the solvent under reduced pressure. Dry at room temperature for 24 hours and pulverize to obtain 76 g of brown demethylated lignin powder.

[0046] Add 20g of demethylated lig...

Embodiment 3

[0047] Example 3. Enzymatic hydrolysis of lignin and dimer acid condensation, grafting to obtain dimer acid modified lignin derivatives, and then Mannich reaction with phenol, aldehyde, amine to prepare epoxy resin curing agent

[0048] Add 20g of enzymatically hydrolyzed lignin, 0.04g of potassium persulfate, 0.04g of copper chloride polymerization inhibitor and 0.06g of ZrO to a three-necked round bottom flask 2 / SO 4 2+ Type solid super acid catalyst, then add 45ml of dioxane solvent, stir until the lignin is dissolved, then open the dropping funnel containing 9g of dimer acid and 24ml-dioxane solution, control the dropping rate, add 15min When finished, heat to 55° C. and pass nitrogen protection. After the addition, continue to react for 4.0 hours, and the acidity does not change. Suction filtration and recovery of the catalyst. After the reaction solution is cooled, the grafted product is slowly added dropwise to 360ml of methanol. The reaction product is precipitated, cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com