Laser-impact strengthening treatment method for steel welded joint of X70 pipeline

A laser shock strengthening and welding joint technology, applied in heat treatment furnaces, heat treatment equipment, furnaces and other directions, can solve the problems of reducing stress corrosion and hydrogen-induced cracking of pipeline steel welded joints, reducing mechanical properties of welded joints, and reducing strength of welded joints, etc. Achieve the effect of improving the resistance to H2S stress corrosion, eliminating the residual tensile stress caused by cracking, and improving the surface microhardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

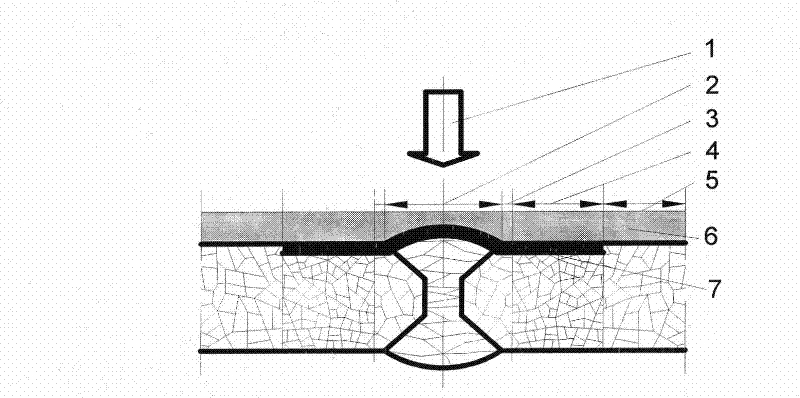

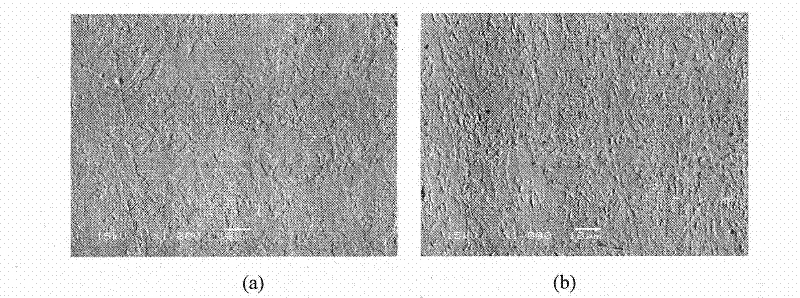

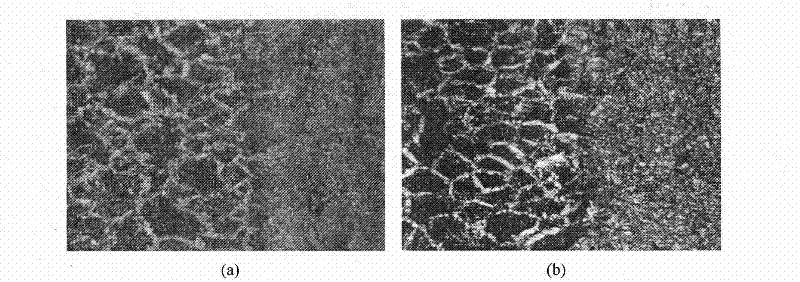

[0015] Using laser shock waves to strengthen the surface of X70 steel welded joints, such as figure 1 As shown, the laser pulse width is 22ns-23ns, the wavelength is 1.054μm, the amplified spontaneous emission pulse width is 1μs, the output laser is focused by a focusing system with a focal length of 2m, the diameter of the focused spot is 5mm-8mm, and the laser pulse power is about 2.0×10 9 W. With 0.1mm aluminum foil as the absorbing layer and 2mm thick water as the constraining layer, laser shock is performed on the surface of the welded joint of pipeline steel. After laser shock treatment, the microstructure of welded joints changed significantly, and the surface grains of welded joints were refined, such as figure 2 shown. The surface layer undergoes severe plastic deformation, and the degree of deformation gradually decreases with the increase of depth, as shown in image 3 As shown, during the laser shock process, the deformation gradually develops from the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com