Preparation method of polymer alkaline anion-exchange membrane

A basic anion and exchange membrane technology, which is applied to fuel cell components, fuel cells, electrical components, etc., can solve the problems of difficult longitudinal and uniform distribution of functional groups, damage to polymer matrix structure, and weakened radiation energy, etc., to achieve The effect of large surface area, good thermal stability, and large ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

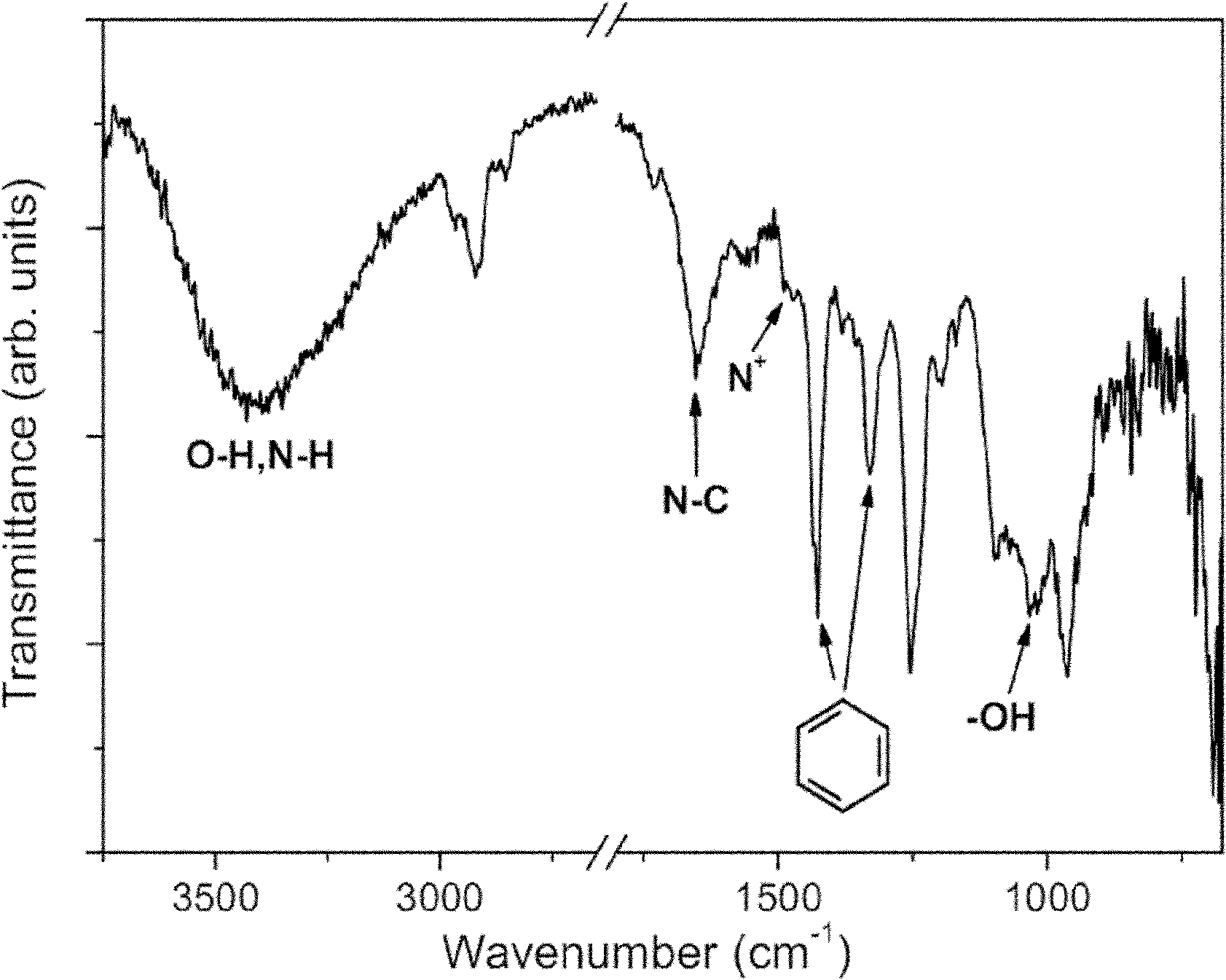

[0025] First weigh 10g of polyvinyl chloride powder and place it in a plasma reactor, vacuumize to the background, pass in argon gas to 30Pa, and discharge at 100W for 30min; then add 20ml of chloromethylbenzene to the powder activated by plasma In ethylene, stir at 60°C for 24 hours, centrifuge, filter, wash and soak repeatedly with deionized water to remove residual monomers on the surface of the polymer, and dry; dissolve the dried powder in tetrahydrofuran to make a mass percentage solution with a concentration of 10%, then salivate into a film, and dry the film; then soak the film in 33% trimethylamine aqueous solution for 48 hours, take it out, and wash it repeatedly with deionized water; finally, immerse the film in 1mol / L NaOH aqueous solution for 48 hours , after taking it out, wash it repeatedly with deionized water and soak it to get the alkaline anion exchange membrane. figure 1 Infrared spectrum data map for plasma grafted basic anion exchange membrane, through f...

Embodiment 2

[0029]First weigh 10g of polyethersulfone powder and place it in the plasma reactor, vacuumize to the background, pass nitrogen gas to 10Pa, and discharge at 140W for 30min; then add the plasma-activated powder into 20ml of chloromethyl styrene , stirred at 60°C for 24 hours, centrifuged, filtered, repeatedly washed and soaked with deionized water to remove residual monomers on the surface of the polymer, and dried; the dried powder was dissolved in N,N-dimethyl formaldehyde Prepare a solution with a mass percentage concentration of 10% in the amide, then salivate to form a film, and dry the film; then soak the film in 33% trimethylamine aqueous solution for 48 hours, take it out, and wash it repeatedly with deionized water; finally immerse the film in 1mol / L NaOH aqueous solution for 48 hours, after taking it out, wash it repeatedly with deionized water and soak it to obtain the alkaline anion exchange membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com