Multilayer electromagnetism modulating structure and preparation method thereof

An electromagnetic and artificial electromagnetic technology, which is applied in the deposition process and alignment overlay process to realize the preparation of the structure, in the field of spin coating, can solve the problems of limited modulation effect, weakened modulation effect, and reduce the distribution density of related units, so as to avoid serious problems. Effect of loss, increase of modulability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

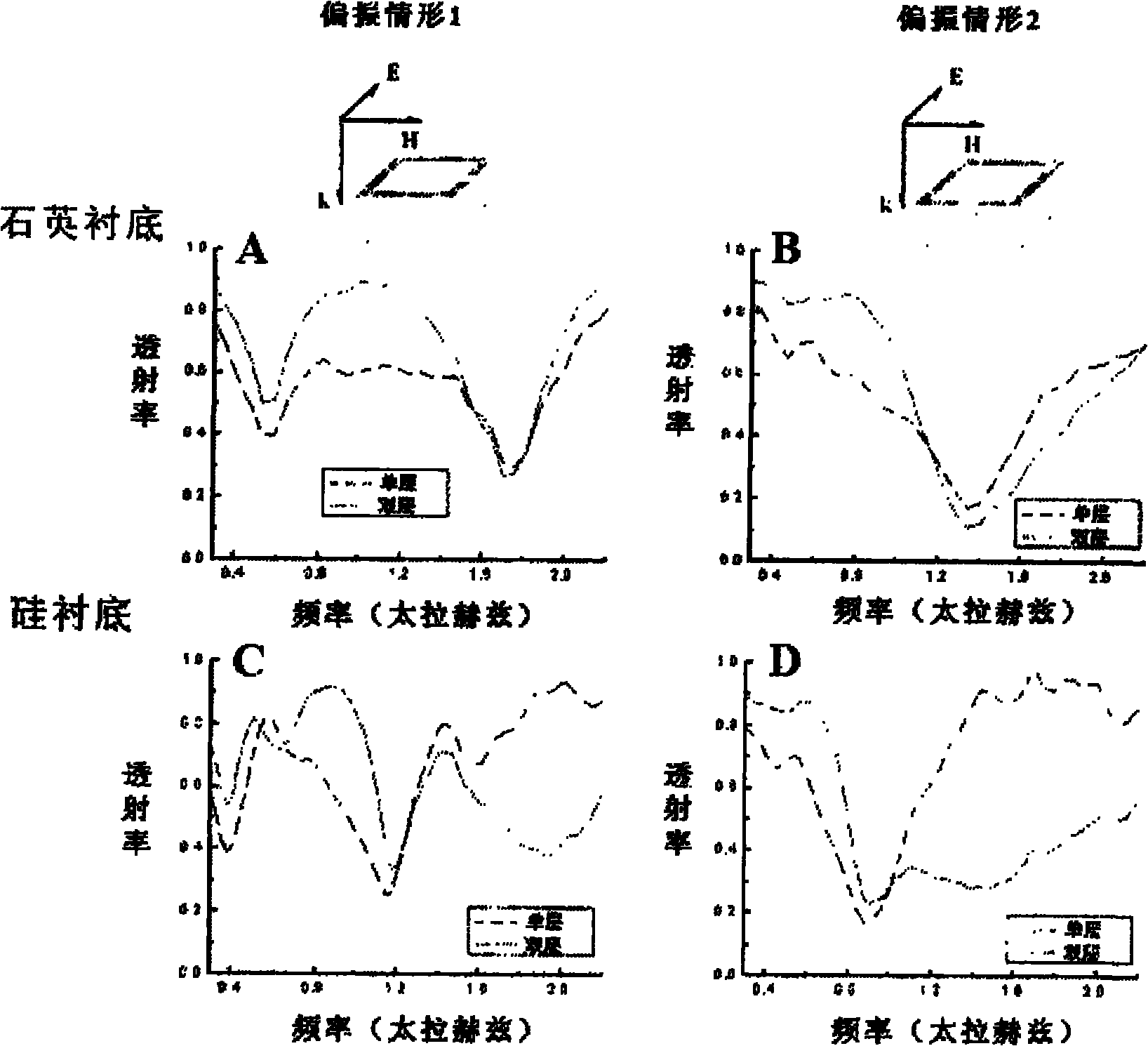

[0055] For electromagnetic waves of different wavelengths to be modulated with target wavelengths, corresponding substrate material layers, medium intermediate layers, and medium covering layers with good transmission characteristics should be selected. For example, for ultraviolet rays with a target wavelength of 200nm-400nm, fluorinated Lead and other materials; for visible light with a target wavelength of 390nm-770nm, materials such as quartz, glass or PET polymers can be used; for infrared rays with a target wavelength of 750nm-1000um, iron-doped zinc selenide infrared transparent ceramics can be used Or JGS3 infrared quartz glass and other materials; for the terahertz electromagnetic wave whose target wavelength to be modulated is 300um-1mm, materials such as silicon, polytetrafluoroethylene plastic or polyimide resin can be used; for the target wavelength to be modulated is 2mm-1mm For microwave ovens, materials such as polypropylene plastics can be used. In this embodi...

Embodiment 2

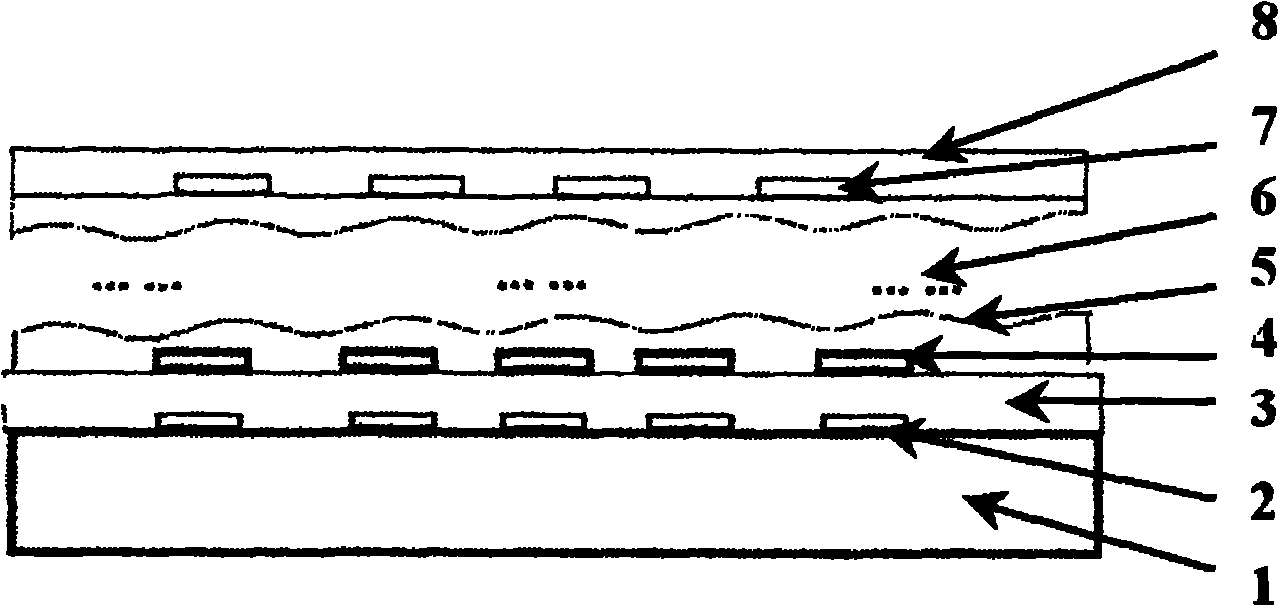

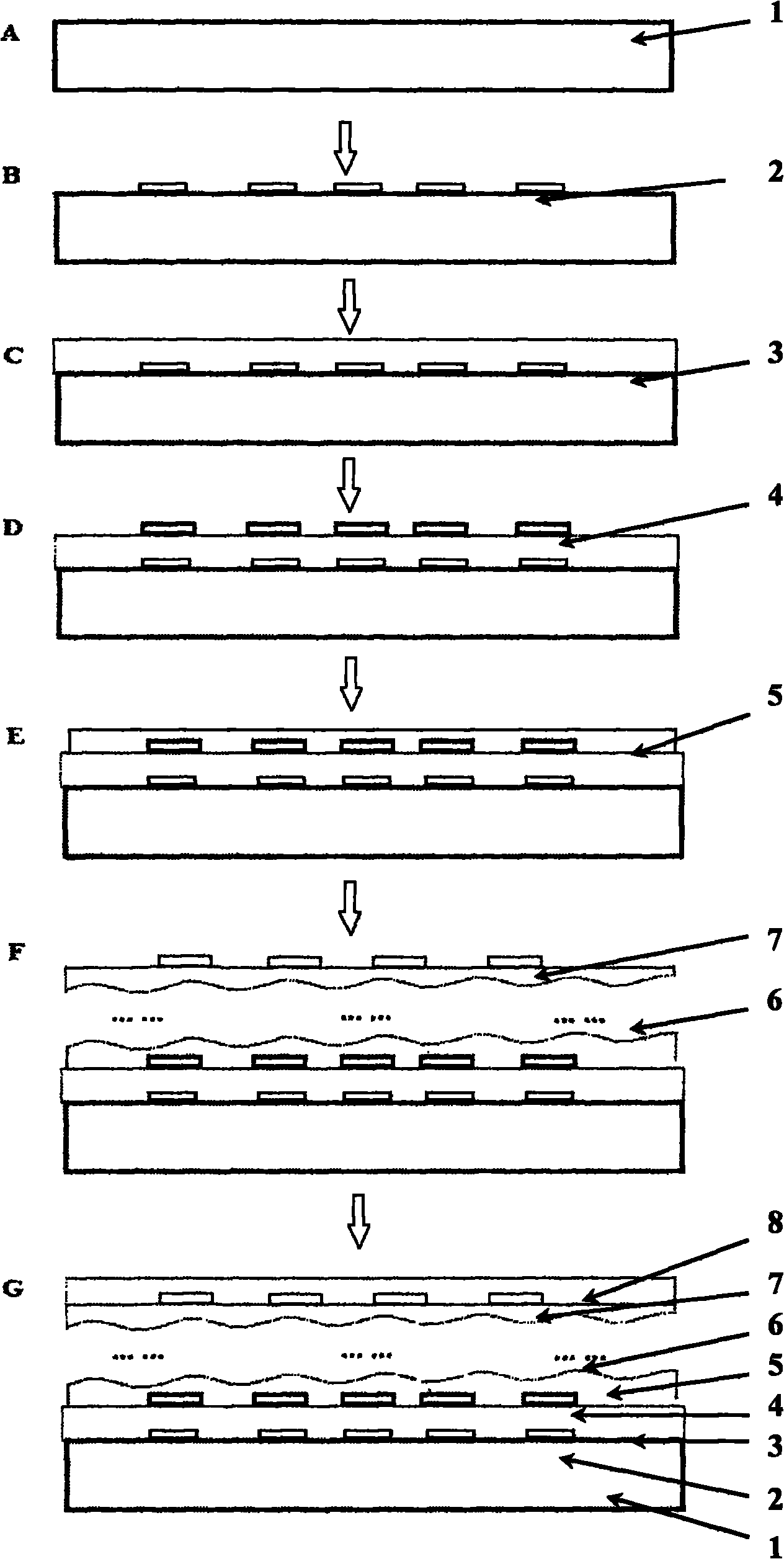

[0065] The preparation of a double-layer combined terahertz electromagnetic wave modulation structure with a double-layer antisymmetric split resonator ring metal structure array on a silicon substrate includes the following steps:

[0066] 1) On an 800 micron thick silicon substrate ( figure 2 A layer of UV photoresist S1813 is spin-coated on the middle A, and the mask plate with the split resonant ring array pattern and four sets of pattern alignment marks is exposed and developed through the ultraviolet exposure system, so that the split resonant ring array and the pattern The alignment marks are transferred to the photoresist, where the split resonant ring unit has a side length dimension of 45 microns, a period length of 60 microns, and an array size of 8 mm x 8 mm;

[0067] 2) Deposit a layer of chromium metal with a thickness of 5 nm and metal gold with a thickness of 100 nm as a transition layer on the silicon substrate treated in step 1) by using a thermal evaporatio...

Embodiment 3

[0072] For the artificial electromagnetic modulation structure of the multi-layer combination in which the electromagnetic waves near the wavelength of 2 microns and 1.5 microns are compounded and modulated at the same time, the realization steps are as follows:

[0073] 1) Select an ITO glass substrate that is transparent to near-infrared electromagnetic waves; spin-coat a layer of electronic resist PMMA on the ITO substrate, use electron beam direct writing exposure and development, and first form a unit length of 300nm on the PMMA, Composed of U-shaped structural units with a line width of 60nm, a period length of 500nm, and an area of 0.8mm×0.8mm, the square first unit structure array pattern forms four cross-shaped patterns near the four corners of the array at the same time alignment marks;

[0074] 2) Utilize electron beam evaporation to deposit 50nm thick metallic silver on the surface of the sample prepared in step 1), then immerse the sample in an acetone solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com