Preparation method of copper alloys with high strength and high electric conductivity

A technology of high conductivity and copper alloy, which is applied in the preparation of copper alloy materials and the preparation of high-strength and high-conductivity aging copper alloy, which can solve the problems of difficult control of alloy composition and limited strengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Melting pure chromium and oxygen-free pure copper with a purity of 98.5% in a vacuum intermediate frequency induction melting furnace according to the ratio of Cu-0.5% Cr, the melting temperature is 1250-1280 ° C, and after 10-15 minutes of heat preservation, Pouring, cutting along the longitudinal direction of the ingot into squares of 12.4 mm×12.4 mm×80 mm.

[0027] The solution treatment temperature is 1000°C, the solution time is 0.5h, and cooled in 5% NaCl aqueous solution.

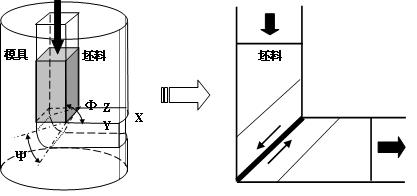

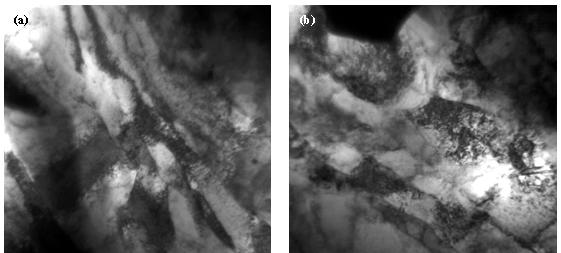

[0028] The inner angle of the equal-channel deformation mold is 110°, the outer angle of the mold is 0°, and the deformation speed at room temperature is about 0.2mm / s. The aging treatment is performed on the samples of the equal-channel deformation of 4 and 8 passes or the equal-channel deformation of the 4-pass and 8-pass The samples of the pass are subjected to 90% rolling deformation and then aging treatment, the aging temperature is 450 ° C, and the aging time is 1 h.

[0029]...

Embodiment 2

[0033] Example 2: Pure chromium, pure zirconium and oxygen-free pure copper are smelted in a vacuum medium frequency induction melting furnace according to the ratio of Cu-0.5%Cr-0.2%Zr, the melting temperature is 1250-1280 ℃, and the temperature is kept for 10-15 minutes Finally, pouring, cutting along the longitudinal direction of the ingot into squares of 12.4 mm×12.4 mm×80 mm.

[0034] The solution treatment temperature is 1000°C, the solution time is 0.5h, and cooled in 5% NaCl aqueous solution.

[0035] The inner angle of the equal-channel deformation mold is 110°, the outer angle of the mold is 0°, and the deformation speed at room temperature is about 0.2mm / s. After 8 passes of equal-channel deformation, aging treatment is performed. The aging temperature is 450°C and the aging time is 1h.

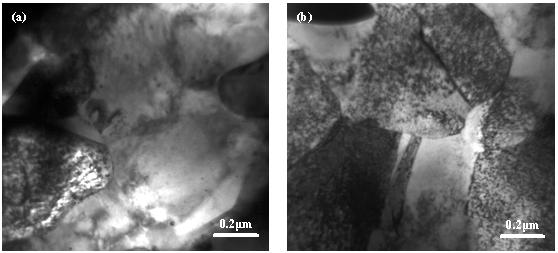

[0036]Cu-0.5%Cr-0.2%Zr alloy is deformed for 8 times, and its tensile strength and electrical conductivity at room temperature reach 530MPa and 34%IACS respectively. After aging tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com