Acidithiobacillus thiooxidans and heap leaching technology using same of middle-grade and low-grade phosphate ore

A technology of thiothiobacillus and acid oxidation, which is applied in the field of microorganisms, can solve the problems of lengthy phosphate fertilizer production process, difficulty in direct processing of phosphate rock, high cost of beneficiation, etc., achieve good leaching effect, reduce beneficiation cost, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

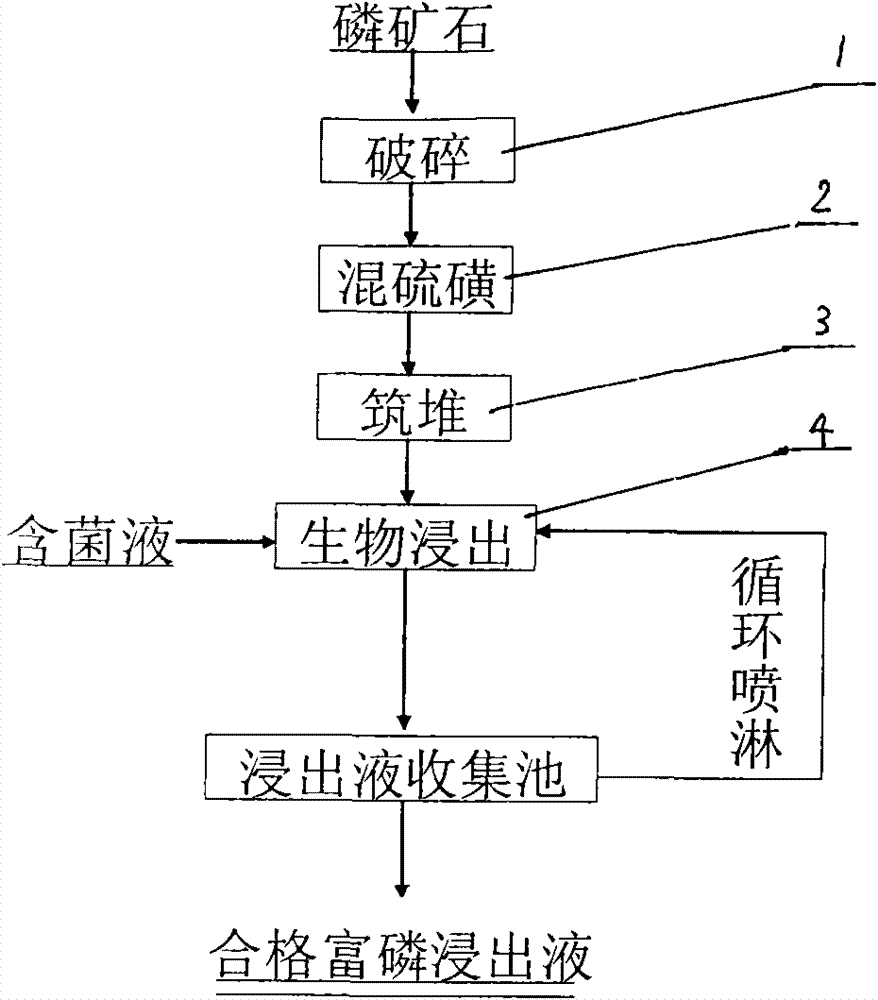

Method used

Image

Examples

Embodiment 1

[0024] First, the low-temperature-preserved phosphoacidophilic thiothiooxidans strain (the bacterial name is Acidithiobacillusthiooxidans RETECH-PS1, preservation unit: China Collection Center for Typical Cultures, address: inside Wuhan University, preservation date: April 25, 2009 , deposit registration number: CCTCC NO: M 209088) in 10ml medium (0.1g KCl, 3g NH 4 SO 4 , 0.5g K 2 HPO 4 ·3H 2 O, 0.5g Mg(SO 4 ) 2 ·7H 2 O and 0.01g Ca(NO 3 ) 2 ) was dissolved in 1L distilled water, and activated in a test tube supplemented with elemental sulfur according to the addition amount of 10g / L. The activated strains were transferred into 100ml culture solution, and after 24 hours of cultivation, the inoculation amount of 10% (v / v) was gradually expanded to the amount required for heap leaching. During the cultivation process, the pH was controlled to be 2.0 and the temperature was 28°C. .

[0025] Phosphate rock to be treated (P 2 o 5 =18.98% by weight) broken down to less t...

Embodiment 2

[0027] First, the low-temperature-preserved phosphoacidophilic thiothiooxidans strain (the bacterial name is Acidithiobacillusthiooxidans RETECH-PS1, preservation unit: China Collection Center for Typical Cultures, address: inside Wuhan University, preservation date: April 25, 2009 , deposit registration number: CCTCC NO: M 209088) in 10ml medium (0.1g KCl, 3g NH 4 SO 4 , 0.5g K 2 HPO 4 ·3H 2 O, 0.5g Mg(SO 4 ) 2 ·7H 2 O and 0.01g Ca(NO 3 ) 2 dissolved in 1L distilled water, and supplemented with elemental sulfur according to the addition amount of 10g / L) in a test tube for activation. The activated strains were transferred into 100ml of culture solution, and after 24 hours of cultivation, the inoculation amount of 10% (v / v) was gradually expanded to the amount required for heap leaching. During the cultivation process, the pH was controlled to be 2.5 and the temperature was 30°C. .

[0028] Phosphate rock to be treated (P 2 o 5 =21.32% by weight) broken down to les...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com