Metal gas diffusion layer used for fuel cell and preparation method thereof

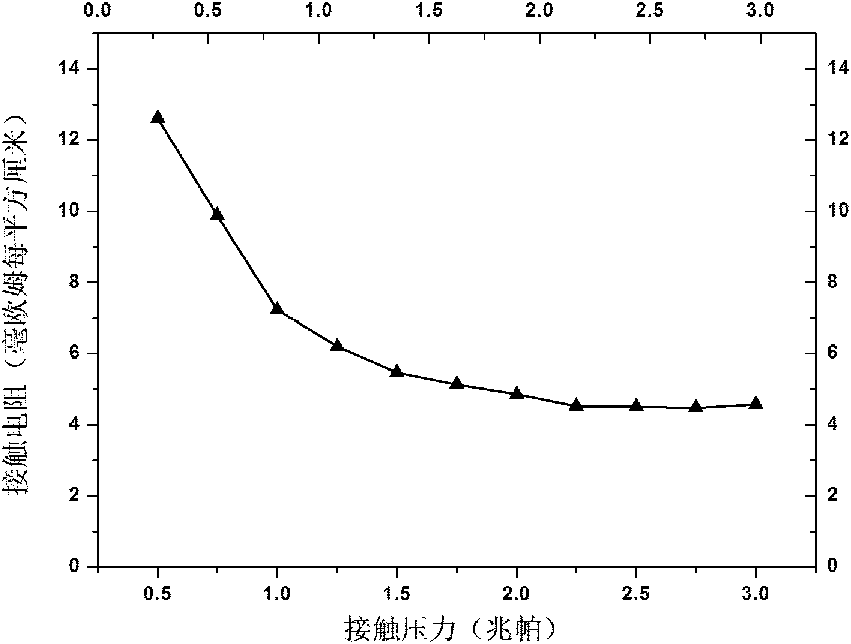

A gas diffusion layer and fuel cell technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of broken gas, small compressive modulus, and difficulty in entering, so as to improve performance, reduce contact resistance, and improve mass transfer The effect of the characteristic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027]The stainless steel wire bundle with a diameter of 1 mm is drawn by the cluster drawing method to obtain a stainless steel fine fiber bundle with an average diameter of 5 μm, and the fine fiber bundle is cut into short fibers with an average length of 3 mm, and the short fibers are prepared by bulking treatment. Bulk felt with randomly distributed short fibers. The bulky felt was put into a vacuum furnace for high-temperature sintering at a temperature of 1000° C. to obtain a stainless steel fiber sintered felt with a thickness of 0.15 mm.

[0028] Cut stainless steel fiber sintered felt samples for pretreatment: wash with 0.2M dilute sodium hydroxide solution for several times to remove surface organic matter, then wash with 0.6M dilute sulfuric acid solution for several times to remove surface metal ions, and then wash with deionized water ,drying. The above cleaning process adopts ultrasonic cleaning technology. Put the pretreated sample into the closed-field unbala...

Embodiment 2

[0032] The stainless steel strands with a diameter of 1mm are stretched by cluster drawing method to obtain stainless steel fine fiber bundles with an average diameter of 10μm, and the fine fiber bundles are cut into short fibers with an average length of 4mm, and the short fibers are randomly oriented after bulking treatment. Distributed bulky felt. Put the bulky felt into a vacuum furnace for high-temperature sintering at a temperature of 1050° C. to obtain a stainless steel fiber sintered felt with a thickness of 0.17 mm.

[0033] Cut stainless steel fiber sintered felt samples for pretreatment: wash with 0.4M dilute sodium hydroxide solution for several times to remove surface organic matter, then wash with 1.0M dilute sulfuric acid solution for several times to remove surface metal ions, wash with deionized water, Cook for 30 minutes in an aqueous solution of 5 wt% oxalic acid at a temperature of 70° C., wash with deionized water, and dry. The above cleaning process adop...

Embodiment 3

[0037] The stainless steel wire bundle with a diameter of 2mm is drawn by the cluster drawing method to obtain a stainless steel fine fiber bundle with an average diameter of 12.5μm, and the fine fiber bundle is cut into short fibers with an average length of 6mm, and the short fibers are prepared by bulking A bulky mat with random distribution of short fibers is obtained. Put the bulky felt into a vacuum furnace for high-temperature sintering at a temperature of 1100° C. to obtain a stainless steel fiber sintered felt with a thickness of 0.19 mm.

[0038] Cut stainless steel fiber sintered felt samples for pretreatment: wash with 1.0M dilute sodium hydroxide solution for several times to remove surface organic matter, then wash with 1.0M dilute sulfuric acid solution for several times to remove surface metal ions, and wash with deionized water , boiled for 30 minutes in an aqueous solution of oxalic acid with a concentration of 10 wt % at a temperature of 70° C., washed with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com