Non-phosphorus scale and corrosion inhibitor, and preparation method and applications thereof

A phosphorus-free scale and corrosion inhibitor technology, applied in descaling and water softening, chemical instruments and methods, water/sludge/sewage treatment, etc. Water saving, environment friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

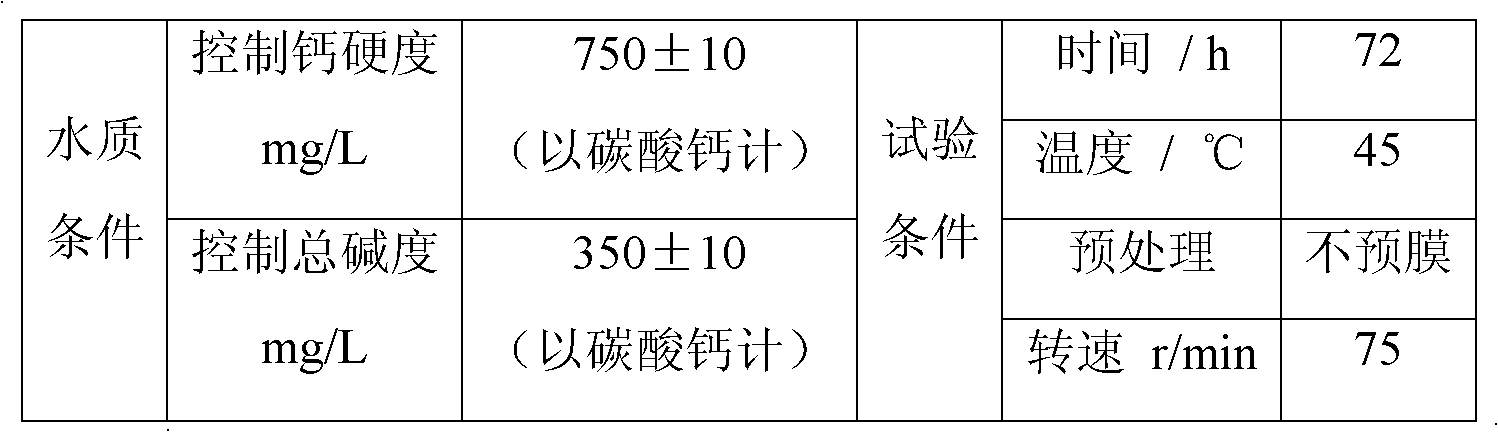

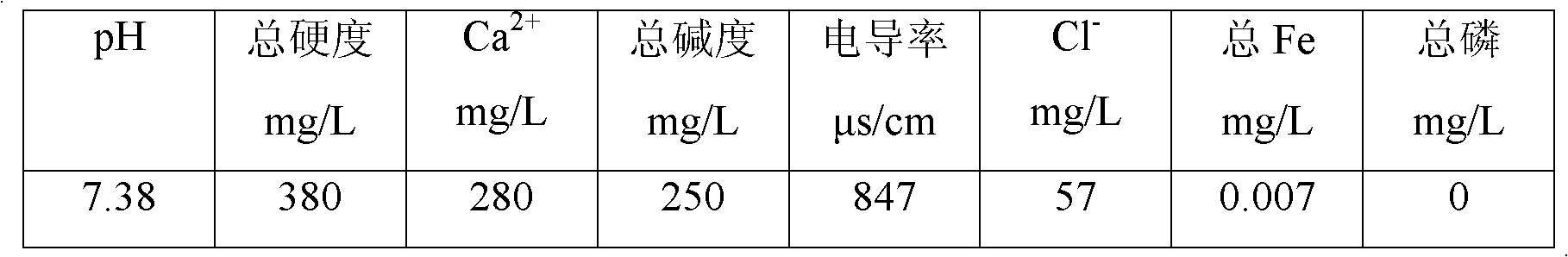

Method used

Image

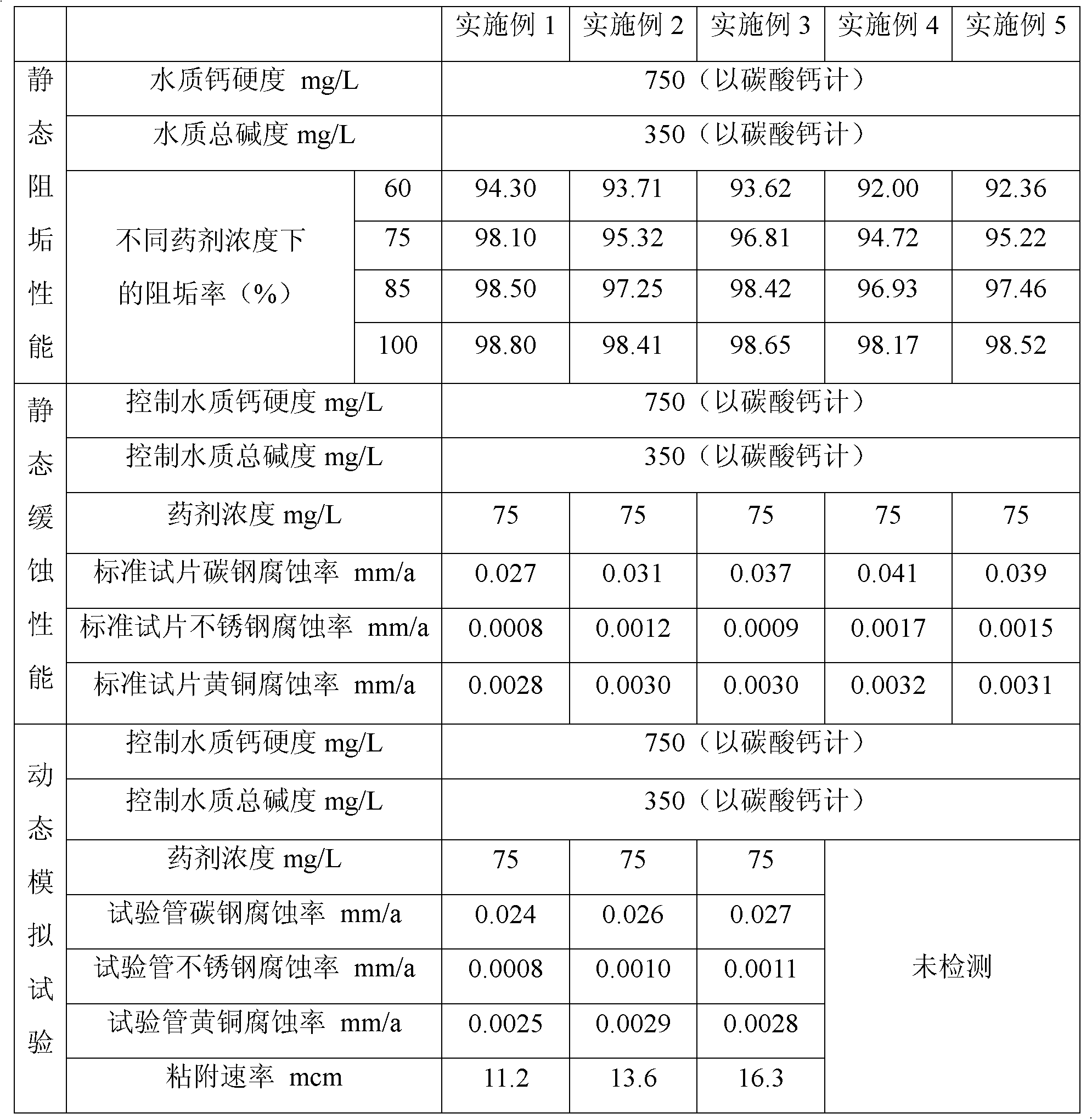

Examples

Embodiment 1

[0043] Add 10 parts of zinc sulfate, 27.5 parts of demineralized water and 5 parts of industrial sulfuric acid (H 2 SO 4 ), fully stirred until the zinc sulfate was completely dissolved, then added 15 parts of hydrolyzed polymass, 15 parts of polyaspartic acid, 20 parts of acrylic acid-acrylic acid ester copolymer, and after stirring evenly, added 3 parts of benzotriazole and 4 parts of industrial ethanol, stirred until the solution is transparent, and the scale and corrosion inhibitor is obtained.

[0044] The product is yellow to reddish-brown liquid, specific gravity ≥ 1.20, pH (1% aqueous solution) 1.0%.

Embodiment 2

[0046] Add 20 parts of zinc sulfate, 24 parts of demineralized water and 4 parts of industrial sulfuric acid (H 2 SO 4 ), fully stirred until the zinc sulfate was completely dissolved, then added 10 parts of hydrolyzed polymass and 35 parts of acrylic acid-acrylic acid ester copolymer in turn, after stirring evenly, added 3 parts of benzotriazole (BTA) and 4 parts of industrial ethanol, and stirred until the solution Transparent, the scale and corrosion inhibitor can be obtained.

[0047] The product is yellow to reddish-brown liquid, specific gravity ≥ 1.20, pH (1% aqueous solution) 1.0%.

Embodiment 3

[0049] Add 10 parts of zinc chloride (ZnCl2 ), 30 parts of demineralized water and 3 parts of industrial hydrochloric acid (HCl), fully stirred until the zinc chloride is completely dissolved, 30 parts of acrylic acid-acrylic acid ester copolymer, after stirring evenly, add 3 parts of tolyltriazole (TTA) and 4 parts of industrial ethanol, stirred until the solution is transparent, and the scale and corrosion inhibitor is obtained.

[0050] The product is yellow to reddish-brown liquid, specific gravity ≥ 1.20, pH (1% aqueous solution) 1.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion rate | aaaaa | aaaaa |

| Corrosion rate | aaaaa | aaaaa |

| Average corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com