Continuous casting tundish for improving cleanliness of molten steel

A continuous casting tundish and tundish technology, which is applied in the field of deep liquid level and large capacity tundish, can solve the problems of underutilization of the stirring effect of argon bubbles, etc., and achieve the effects of promoting floating separation, prolonging residence time, and enhancing metallurgical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

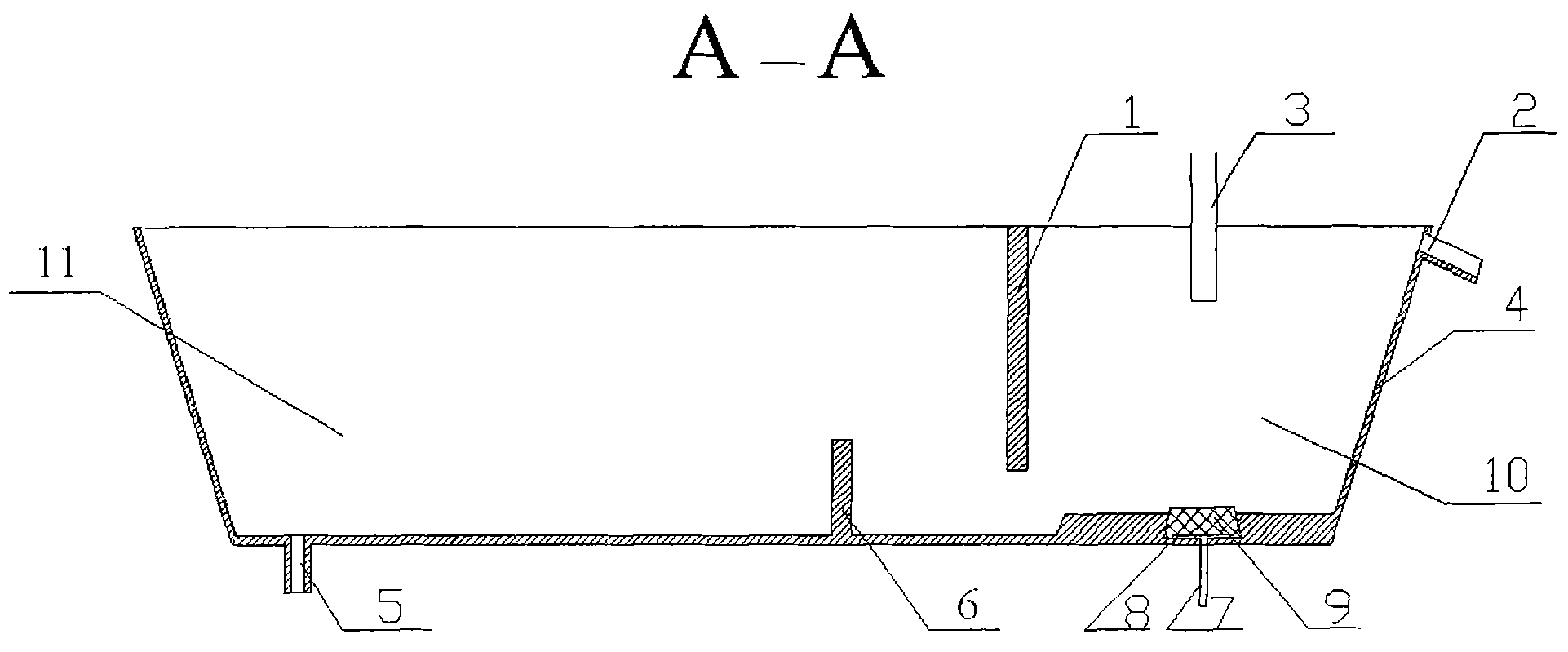

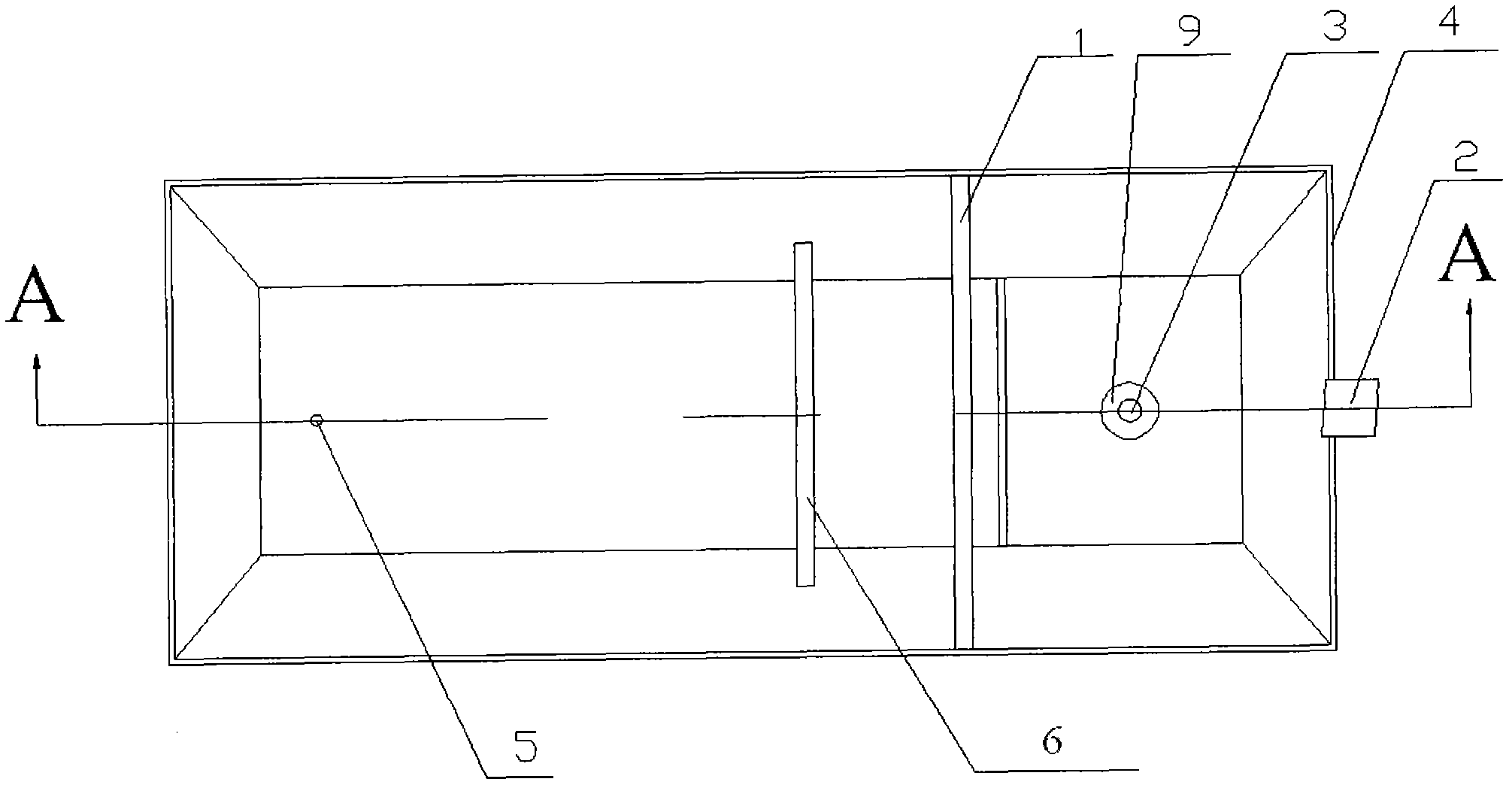

[0037] Such as figure 1 with image 3 As shown, a continuous casting tundish for improving the cleanliness of molten steel includes a slag retaining wall 1, an overflow groove 2, a ladle nozzle 3, a tundish main body 4, a tundish outlet 5, a dam 6, and a ventilating brick 9 composition.

[0038] The lower nozzle 5 of the tundish is installed on one side of the bottom of the main body 4 of the tundish; The sliding nozzle at the bottom of the ladle above the area 10, the lower end is immersed in 8mm-15mm below the molten steel surface of the tundish); the dam 6 is installed at the bottom of the main body 4 of the tundish. The slag retaining wall 1 is installed between the ladle shroud 3 and the dam 6 , and the slag retaining wall 1 divides the tundish 4 into two parts, the pouring impact area 10 and the pouring area 11 . The slag retaining wall 1 is trapezoidal with a large upper part and a smaller lower part, both sides are connected with the two side walls of the tundish main...

Embodiment 2

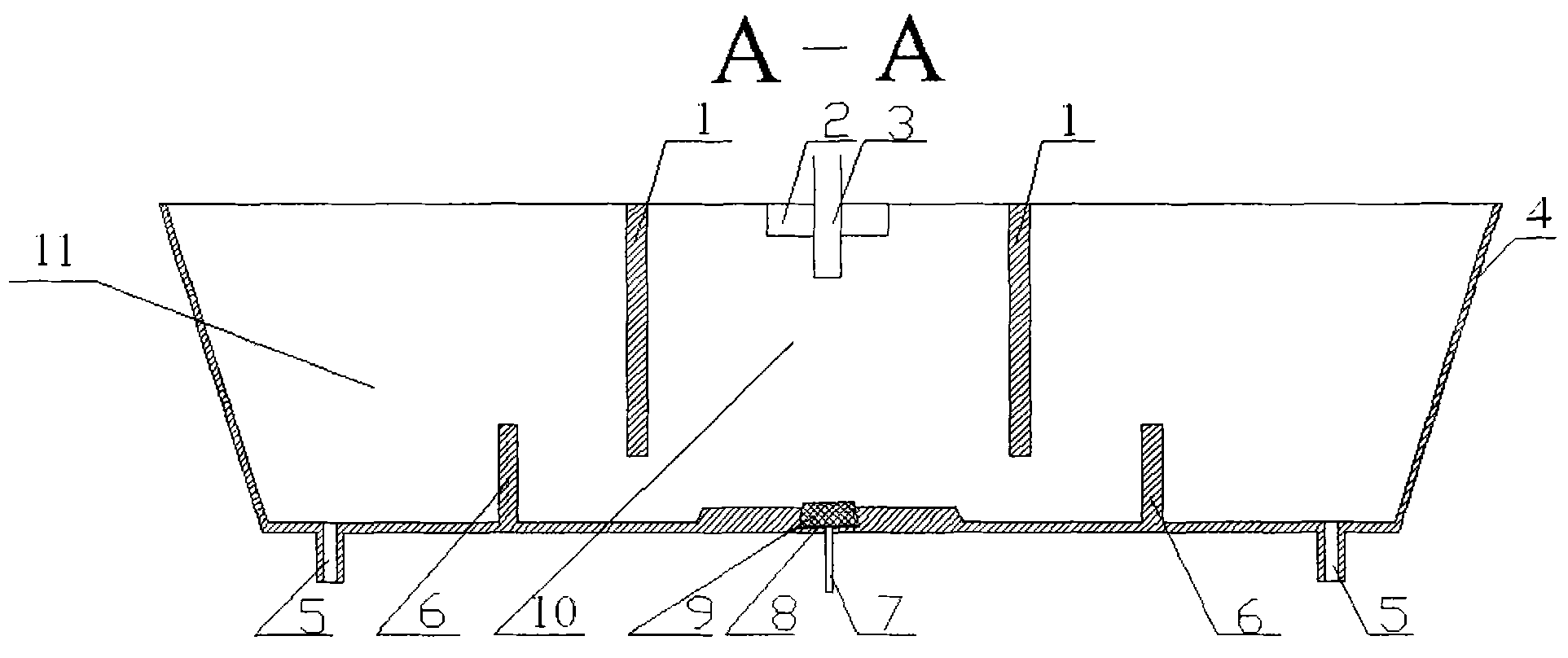

[0042] Such as figure 2 with Figure 4 As shown, a continuous casting tundish for improving the cleanliness of molten steel includes a slag retaining wall 1, an overflow groove 2, a ladle nozzle 3, a tundish main body 4, a tundish outlet 5, a dam 6, and a ventilating brick 9 composition.

[0043] Two tundish nozzles 5 are installed on both sides of the bottom of the tundish main body 4; the large ladle shroud 3 is installed on the sliding nozzle at the top ladle bottom of the tundish main body 4 (the upper end of the large ladle shroud 3 is installed in the middle On the sliding nozzle at the bottom of the ladle above the impact area 10 of the injection flow, the lower end is immersed in 8mm-15mm below the molten steel surface of the tundish); two dams 6 are installed at the bottom of the main body 4 of the tundish. Two slag retaining walls 1 are installed between the ladle long nozzle 3 and the dam 6, and the slag retaining wall 1 divides the tundish 4 into an injection im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com