Method for preparing magnesium alloy solder

A technology of magnesium alloy and brazing filler metal, which is applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problem of mixing impurities in magnesium alloy brazing filler metal, uneven distribution of trace alloy elements of alloy elements, and coarse magnesium alloy brazing filler metal grains, etc. problems, to achieve the effect of reducing inclusion content, uniform distribution and segregation improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

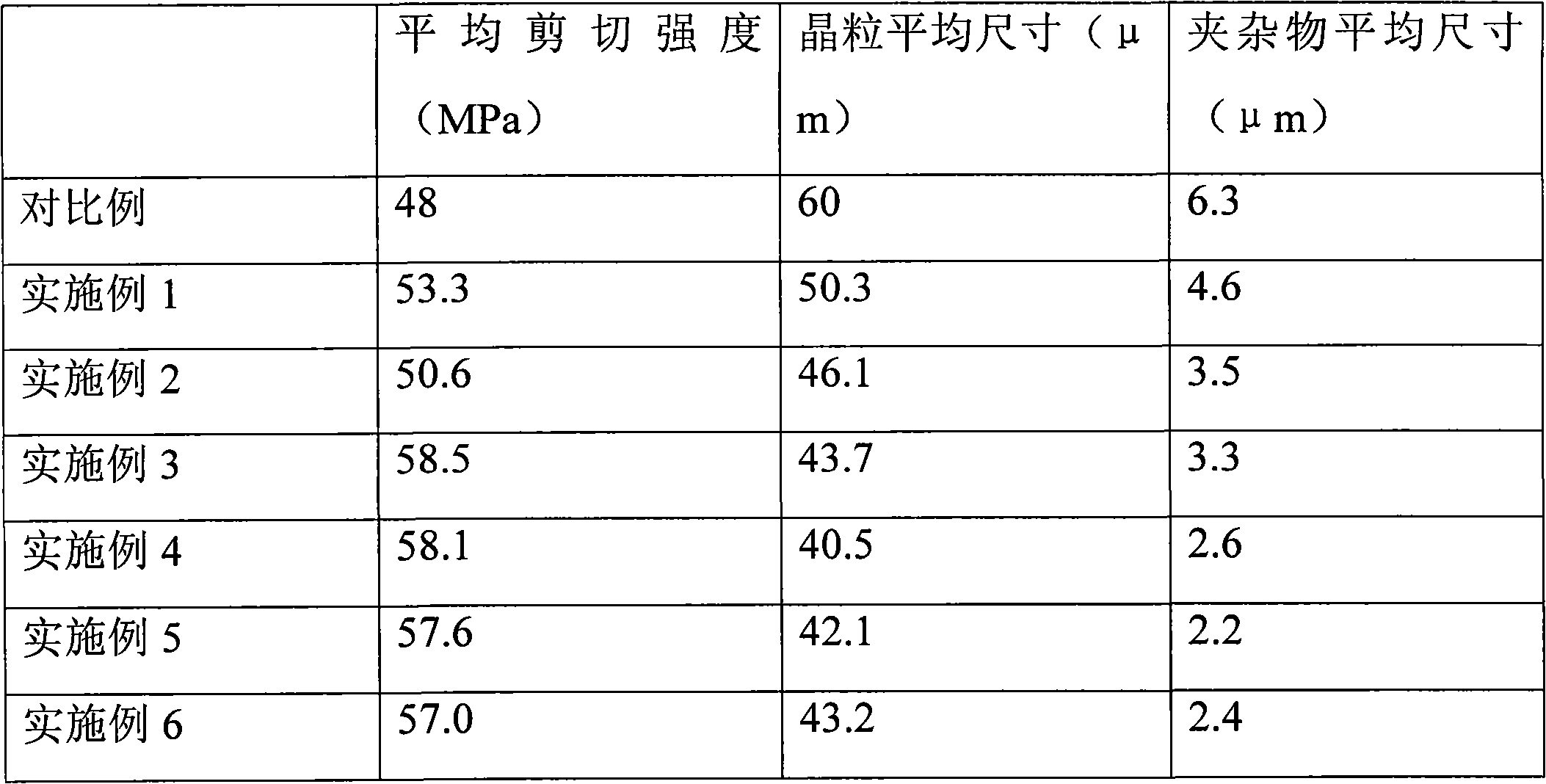

Examples

Embodiment 1

[0026] Preheat the crucible to 100 °C. Sprinkle 60g covering agent on the bottom of the crucible, the composition of the covering agent is 35wt% BaCl 2 , 30%wt% LiCl, 10.0wt% KCl and 25wt% CaF 2 . Put 50g of magnesium ingot and 950g of zinc ingot in the crucible. Heating to 700°C under protective atmosphere and mechanical stirring conditions and then keeping it warm. After the alloy is completely melted, remove the slag, stir for 2 minutes and then cool down. After the melt temperature drops to 680°C, keep it warm. Insert the ultrasonic rod preheated to 680°C into the molten magnesium alloy solder, and immerse the ultrasonic rod about 5mm below the alloy liquid surface. , and then apply ultrasonic waves, the ultrasonic frequency is 18kHz, and the ultrasonic intensity is 0.5W / cm 2 , the time is 10s. After the treatment, the ultrasonic rod was removed, and the alloy solution was left to stand for 5s, and poured into a stainless steel mold after the temperature dropped to 67...

Embodiment 2

[0028] Preheat the crucible to 150 °C. Sprinkle 60g covering agent on the bottom of the crucible, the composition of the covering agent is 35wt% BaCl 2 , 30%wt% LiCl, 10.0wt% KCl and 25wt% CaF 2 . Put 500g of magnesium ingots and 500g of zinc ingots into the crucible, and sprinkle 60g of covering agent. Heating to 700°C under protective atmosphere and mechanical stirring conditions and then keeping it warm. After the alloy is completely melted, remove the slag, stir for 3 minutes and then cool down. The melt temperature drops to 680°C and then keep warm. Insert the ultrasonic rod preheated to 680°C into the molten magnesium alloy solder, and immerse the ultrasonic rod about 10mm below the alloy liquid surface. , and then apply ultrasonic waves, the ultrasonic frequency is 19kHz, and the ultrasonic intensity is 0.8W / cm 2 , the time is 20s. After the treatment, the ultrasonic rod was removed, and the alloy liquid was left to stand for 20s, and poured into a stainless steel ...

Embodiment 3

[0030] Preheat the crucible to 180 °C. Sprinkle 60g covering agent on the bottom of the crucible, the composition of the covering agent is 35wt% BaCl 2 , 30%wt% LiCl, 10.0wt% KCl and 25wt% CaF 2 . Put 660g magnesium ingot, 72g aluminum ingot and 600g zinc ingot in the crucible. Heating to 720°C under protective atmosphere and mechanical stirring conditions and then keeping it warm. Remove the slag after the alloy is completely melted, cool down after stirring for 4 minutes, keep the melt temperature down to 680°C and keep it warm, insert the ultrasonic rod preheated to 680°C into the molten magnesium alloy solder, and immerse the ultrasonic rod about 10mm below the alloy liquid surface , and then apply ultrasonic waves, the ultrasonic frequency is 20kHz, and the ultrasonic intensity is 1W / cm 2 , the time is 30s. After the treatment, the ultrasonic rod was removed, and the alloy liquid was left to stand for 50s, and poured into a stainless steel mold after the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com