Method for separating neutral longan polysaccharide fraction

A technology of longan polysaccharides and separation methods, applied in the field of separation of neutral longan polysaccharide fractions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Select fresh longan raw materials, dry them, remove the skin and core, and crush them to obtain longan pulp; add 30 times the weight of water to the longan pulp, heat it to 80°C, and place it under 300W ultrasonic intensity for 30 minutes, cancel the ultrasonic and continue leaching Extract for 120 minutes; the extract is filtered and separated from the pulp residue, concentrated in vacuum at 60°C until slightly viscous, and the concentrated solution is collected and vacuum freeze-dried to obtain the longan pulp aqueous extract.

[0026] D301-F anion exchange resin is firstly soaked in water, poured out the suspended particles and impurities in the upper layer, then soaked in 4% NaCl solution by weight for 4 hours, and then washed with water; then soaked in 4% NaOH solution by weight for 4 hours , washed with water to a near-neutral pH value, and finally dried at 50°C for later use.

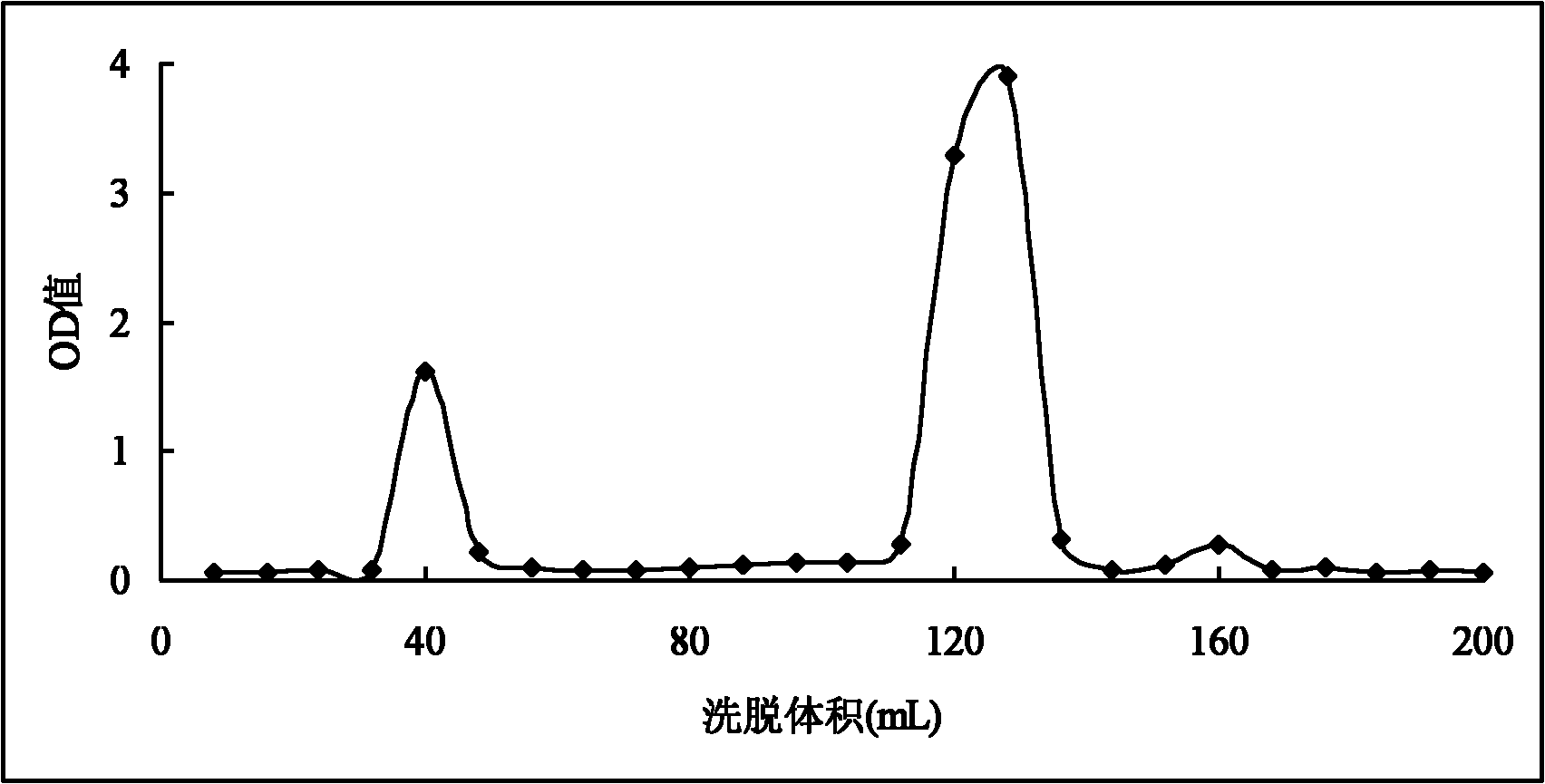

[0027] Dissolve the longan pulp extract in 20 times the weight of water, add 3 times t...

Embodiment 2

[0033]Select fresh longan raw materials, dry them, remove the skin and core, and crush them to obtain longan pulp; add 35 times the weight of water to the longan pulp, heat it to 75°C, and place it under 250W ultrasonic intensity for 40 minutes, cancel the ultrasonic and continue leaching Extract for 110 minutes; the extract is filtered and separated from the pulp residue, then concentrated in vacuum at 65°C until slightly viscous, and the concentrated solution is collected and vacuum freeze-dried to obtain the water extract of longan pulp.

[0034] D301-F anion exchange resin is firstly soaked in water, poured out the suspended particles and impurities in the upper layer, then soaked in 4.5% NaCl solution by weight for 3.5 hours, and then washed with water; then soaked in 4.5% by weight NaOH solution 3.5h, washed with water to near neutral pH value, and finally dried at 52.5°C for later use.

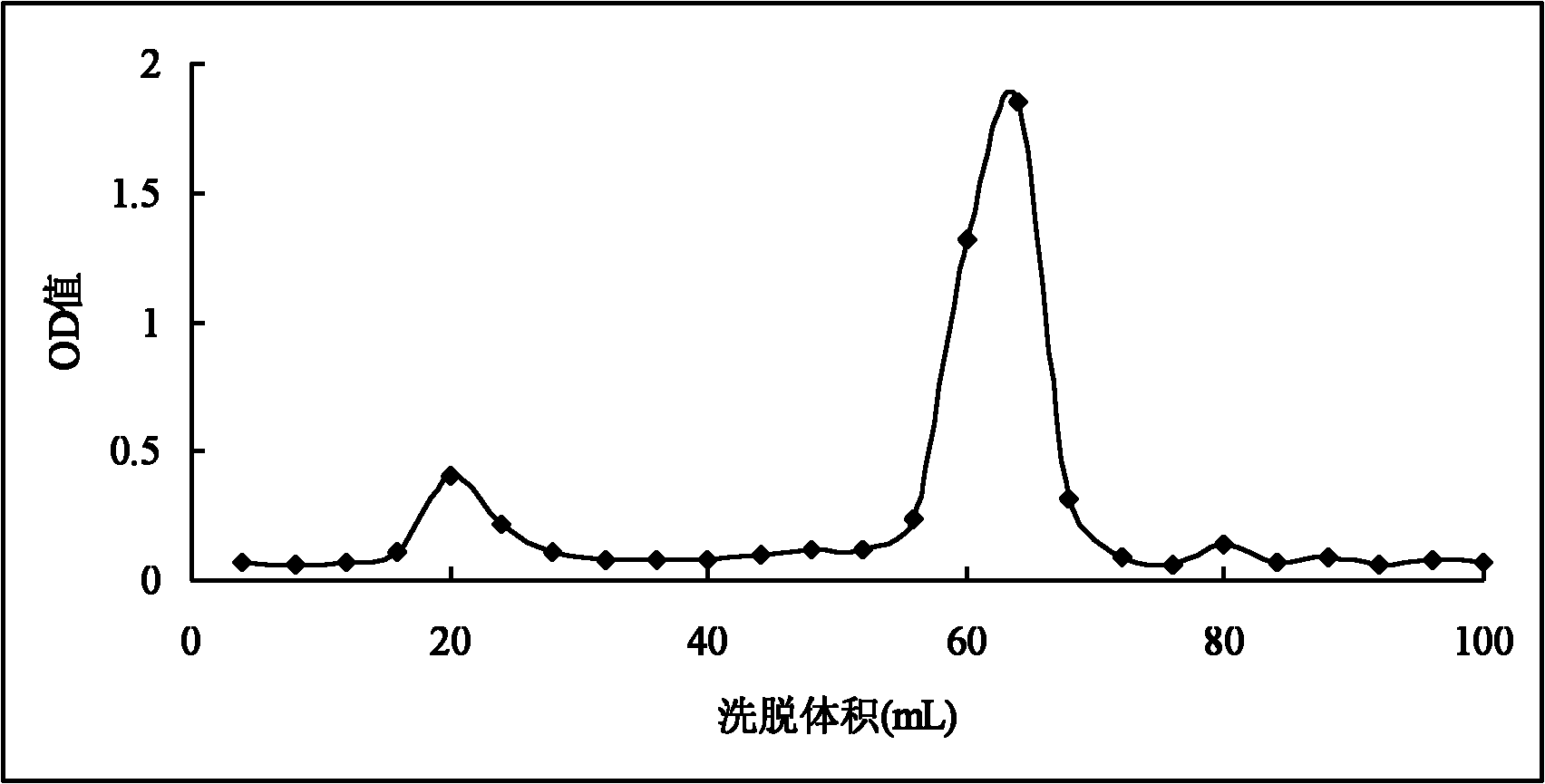

[0035] Dissolve the longan pulp extract in 25 times the weight of water, add 3.5 ti...

Embodiment 3

[0041] Select fresh longan raw materials, dry them, remove the skin and core, and crush them to obtain longan pulp; add 40 times the weight of water to the longan pulp, heat it to 70°C, and place it under 200W ultrasonic intensity for 50 minutes, cancel the ultrasonic and continue leaching Extracted for 100 min; the extract was filtered and separated from the pulp residue, concentrated in vacuum at 70°C until slightly viscous, and the concentrated solution was collected and vacuum freeze-dried to obtain the longan pulp aqueous extract.

[0042] D301-F anion exchange resin is firstly soaked in water, poured out the suspended particles and impurities in the upper layer, then soaked in 5% NaCl solution for 3 hours and washed with water; then soaked in 5% NaOH solution for 3 hours , washed with water to a near-neutral pH value, and finally dried at 55°C for later use.

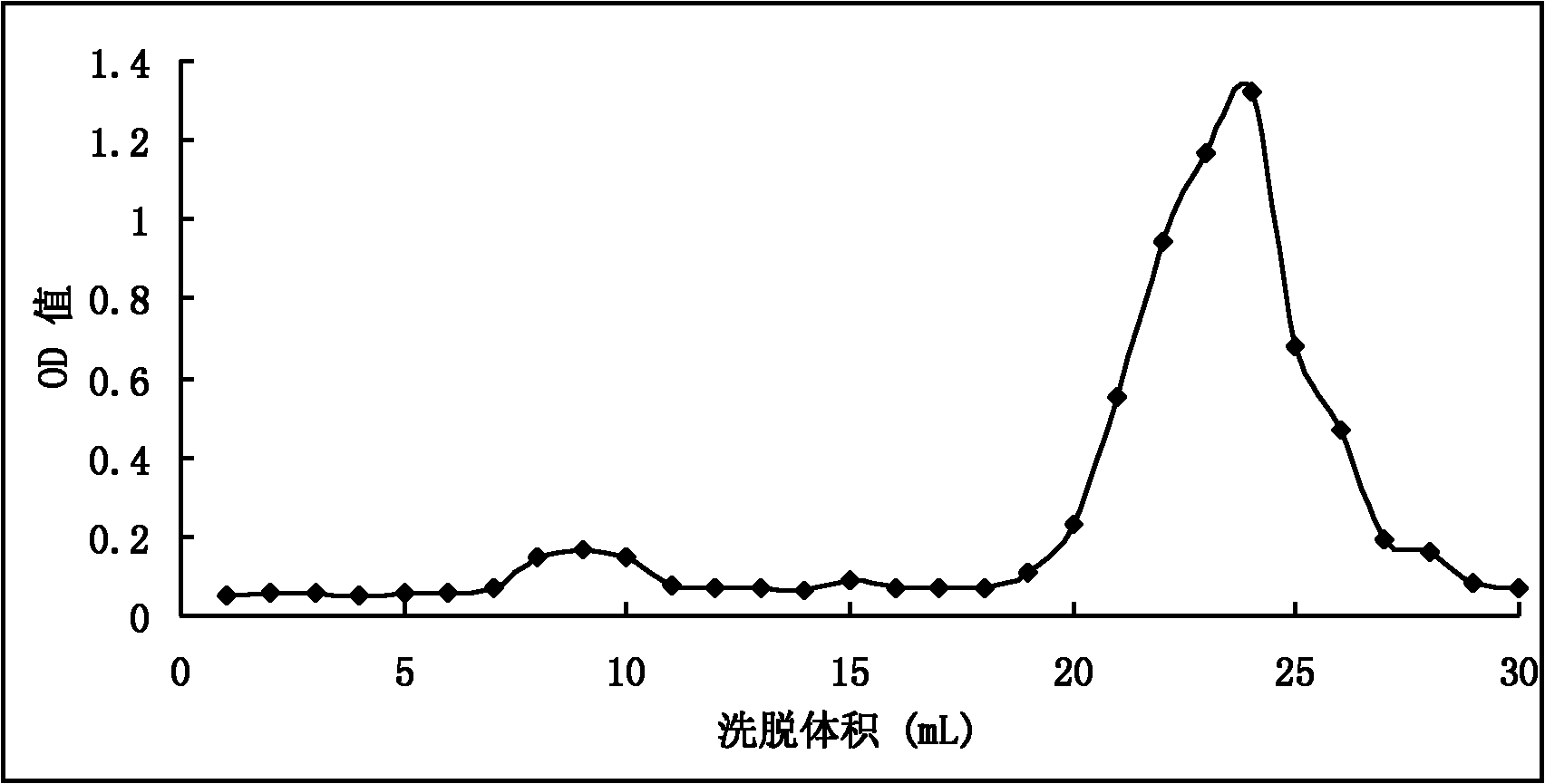

[0043] Dissolve the longan pulp extract in 30 times the weight of water, add 4 times the D301-F anion exchange r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com