Solar auxiliary heating methane production device

A technology for auxiliary heating and production equipment, which is applied in the direction of gas production bioreactors, biochemical instruments, energy wastewater treatment, etc., and can solve the problems that sludge cannot be closed and circulated, sludge loses gas production efficiency, and mineral energy resources are exhausted. , to achieve the effect of ensuring the residence time, high degree of automation and promoting full contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

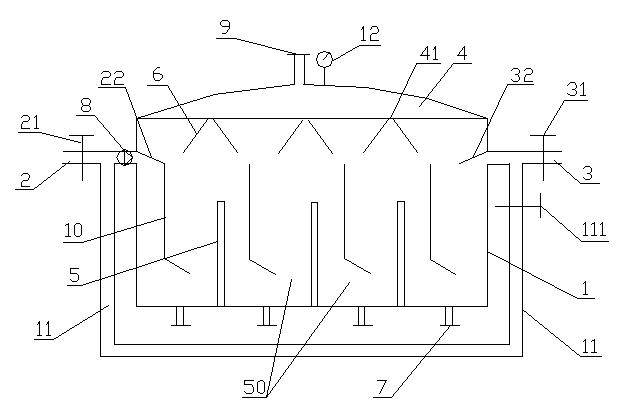

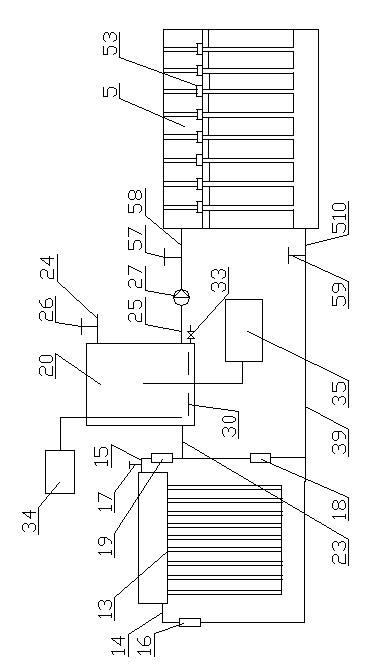

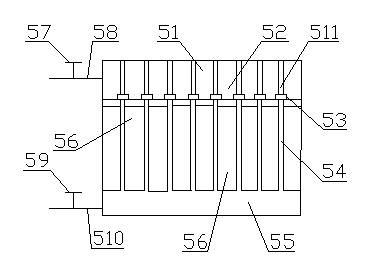

[0031] like figure 1 The shown solar-assisted heating biogas production device includes a biomass biogas fermentation system and an auxiliary heating system. The biomass biogas fermentation system includes an anaerobic reaction box 1 and a gas storage tank 4 on the upper part of the anaerobic reaction box 1 for storing the produced biogas , The anaerobic reaction box 1 is provided with a feed port 2 and a discharge port 3, a feed port valve 21 and a discharge port valve 31, and a feed pump 8 is provided between the feed port valve 21 and the anaerobic reaction box 1. For continuous feeding and sludge recycling. A return pipe 11 is provided between the anaerobic reaction box 1 and its outlet valve 31, and a return pipe valve 111 is provided on the return pipe 11, and the other end of the return pipe 11 is connected between the feed inlet valve 21 and the feed pump 8 on the pipeline. The sludge flows back into the feed pipe through the return pipe 11. On the one hand, it mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com