Preparation method of gas separation composite film

A gas separation and composite membrane technology, applied in semipermeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve problems such as uneven coating, increased mass transfer resistance of transition layer, etc., and achieve permeability and separation performance Improvement, simplification of equipment process and cost, and the effect of saving pre-wetting steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

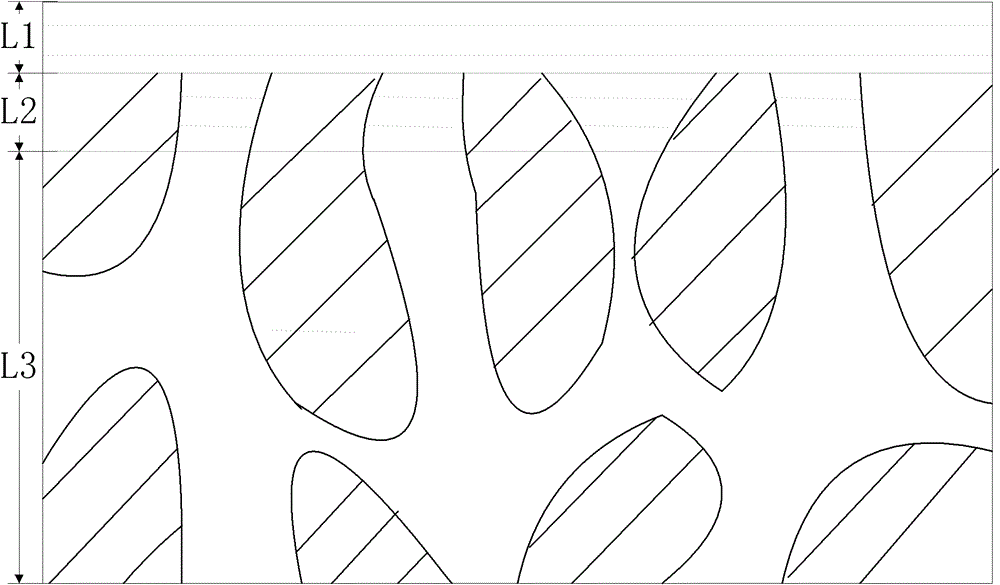

Image

Examples

Embodiment 1

[0025] Use 140 parts of polyacrylonitrile with a viscosity average molecular weight of 135000, add 860 parts of DMF, and prepare a solution with a PAN concentration of 14%wt, add 60 parts of LiCl, mix well, and cast on polyester non-woven fabric. The thickness is 250 μm, and the PAN base film is made by gelling in an aqueous solution with a LiCl concentration of 12% wt. Dissolve 70 parts of siloxane prepolymer in 930 parts of isooctane, add 3 parts of cross-linking agent, 2 parts of catalyst, stir at 20°C for 60 minutes, and prepare the separation layer membrane liquid. The separation layer membrane solution was uniformly coated on the PAN base film, dried at room temperature for 15 minutes, heat-treated at 90°C for 30 minutes, soaked in deionized water for 24 hours, and dried to obtain composite membrane 1. The resulting composite membrane was measured at 25 °C for its O 2 , N 2 , propylene (C 3 h 6 ) penetration and separation properties are: J N2 =0.342m 3 m -2 ·atm ...

Embodiment 2

[0029] Using 160 parts of polyacrylonitrile with a viscosity-average molecular weight of 135,000, adding 840 parts of DMF to prepare a solution with a PAN concentration of 16% wt, adding 50 parts of CaCl 2 , after mixing evenly, it was cast on polyester non-woven fabric with a cast thickness of 250 μm, in CaCl 2 Concentration of 10%wt aqueous gel to make PAN base film. Dissolve 80 parts of polyoctylmethylsiloxane prepolymer in 920 parts of isooctane, add 4 parts of cross-linking agent, 3 parts of catalyst, stir at 40°C for 10 minutes, and prepare the separation layer membrane liquid. The separation layer membrane solution was evenly coated on the PAN base film, dried at room temperature for 10 minutes, heat-treated at 120°C for 10 minutes, soaked in deionized water for 24 hours, and dried to obtain composite membrane 3. The resulting composite membrane was measured at 25 °C for its O 2 , N 2 , propylene (C 3 h 6 ) penetration and separation properties are: J N2 =0.315m ...

Embodiment 3

[0031] Adopting 160 parts of polyacrylonitrile with a viscosity-average molecular weight of 135000, adding 840 parts of DMF, it is prepared into a solution with a PAN concentration of 10% wt, adding 80 parts of Al(NO 3 ) 3 , after mixing evenly, it was cast on polyester non-woven fabric with a casting thickness of 200 μm, in Al(NO 3 ) 3 Concentration of 10%wt aqueous gel to make PAN base film. Dissolve 60 parts of polyoctylmethylsiloxane prepolymer in 940 parts of isooctane, add 2 parts of cross-linking agent and 2 parts of catalyst, stir at 80°C for 5 minutes, and prepare the separation layer membrane liquid. The separation layer membrane solution was uniformly coated on the PAN base film, dried at room temperature for 8 minutes, heat treated at 80°C for 20 minutes, soaked in deionized water for 24 hours, and dried to obtain composite membrane 4. The resulting composite membrane was measured at 25 °C for its O 2 , N 2 , propylene (C 3 h 6 ) penetration and separation p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com