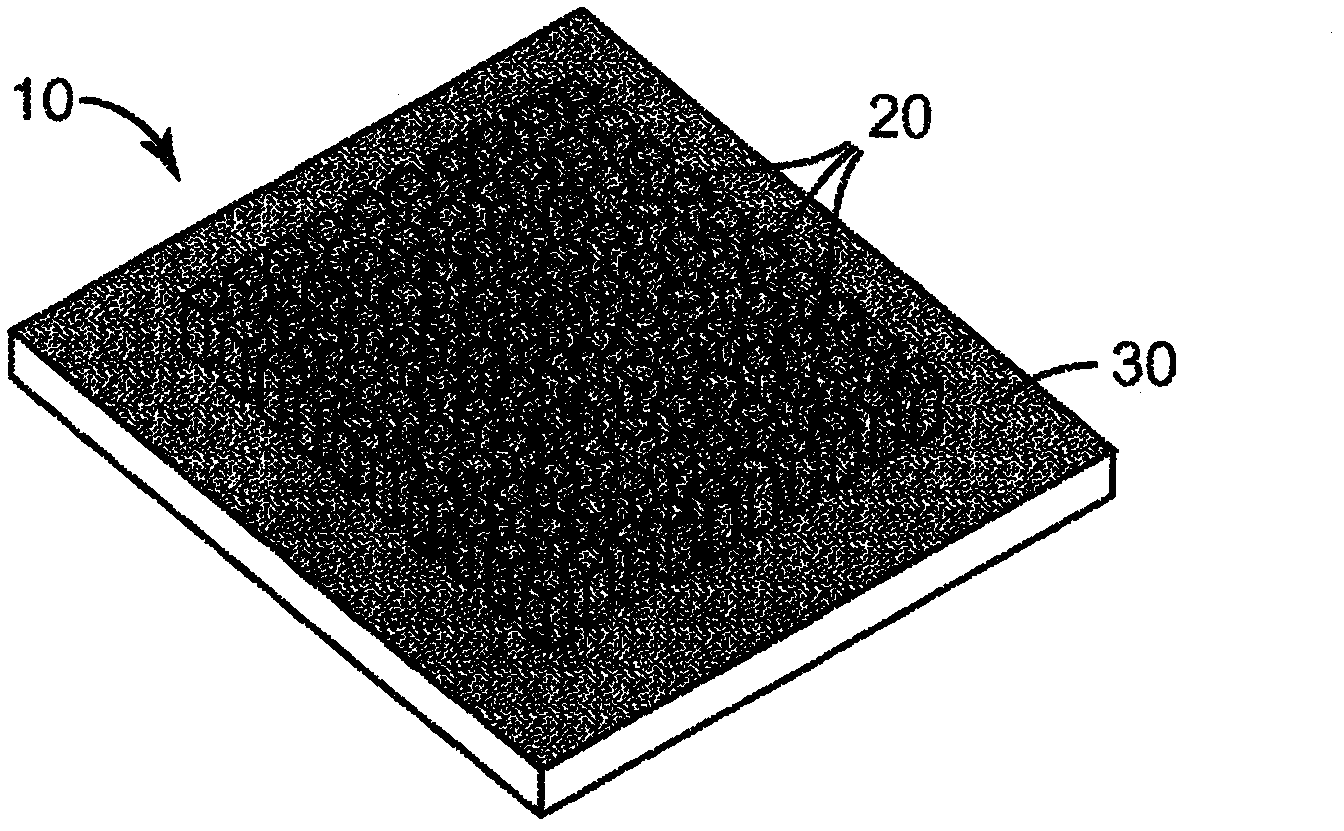

Porous structured thermal transfer article

A porous structure, heat transfer technology, applied in heat transfer modification, indirect heat exchanger, heat exchange equipment, etc., can solve problems such as difficult to carry out, poor overall thermal conductivity of the coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0063] Material

[0064] The precursor metal body comprised copper particles of 325 mesh or less with silver sputtered on them using the method described in US Patent Publication 2005 / 0095189 Al. The obtained particles contained 0.4-0.9 wt% Ag. The source of these copper particles was Chem Copp copper powder 1700 FPM (American Chemet Corporation, Deerfield, Il).

[0065]Structured heat transfer articles were prepared and boiling experiments were performed using the method described below.

[0066] Preparation of Heat Transfer Articles

example 1

[0070] Heat transfer coatings comprising precursor metal bodies were prepared as described above. Copper particles having a diameter of 75 μm and a length of 2 mm were prepared by chopping a piece of copper wool (#706, manufactured by Palmer Engineered Products (Springfield OH)). These copper fibers were manually placed at a density of about 0.025g / cm 2 Applied to the top surface of the circular zone of the heat transfer coating containing precursor metal bodies.

[0071] Both Comparative Example and Example 1 were placed in a vacuum furnace. Reduce the pressure to below 0.001 mm Hg while raising the furnace temperature to 300°C at about 14°C / min and hold at 300°C for 15 minutes to remove oil. The furnace was then heated to 850°C at about 14°C / minute, held at this temperature for one hour, and then allowed to cool to near room temperature, after which the vacuum was broken and the part removed.

[0072] liquid pool boiling

[0073] Set up a setup capable of rapidly testi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com