Method of modeling the time gradient of the state of a steel volume by means of a computer and corresponding objects

a technology of time gradient and steel volume, applied in the field of method of modeling the time gradient of the state of a steel volume, can solve the problems of great computing outlay and practically no effect on the quality of modeling, and achieve the effect of keeping down the computing effor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

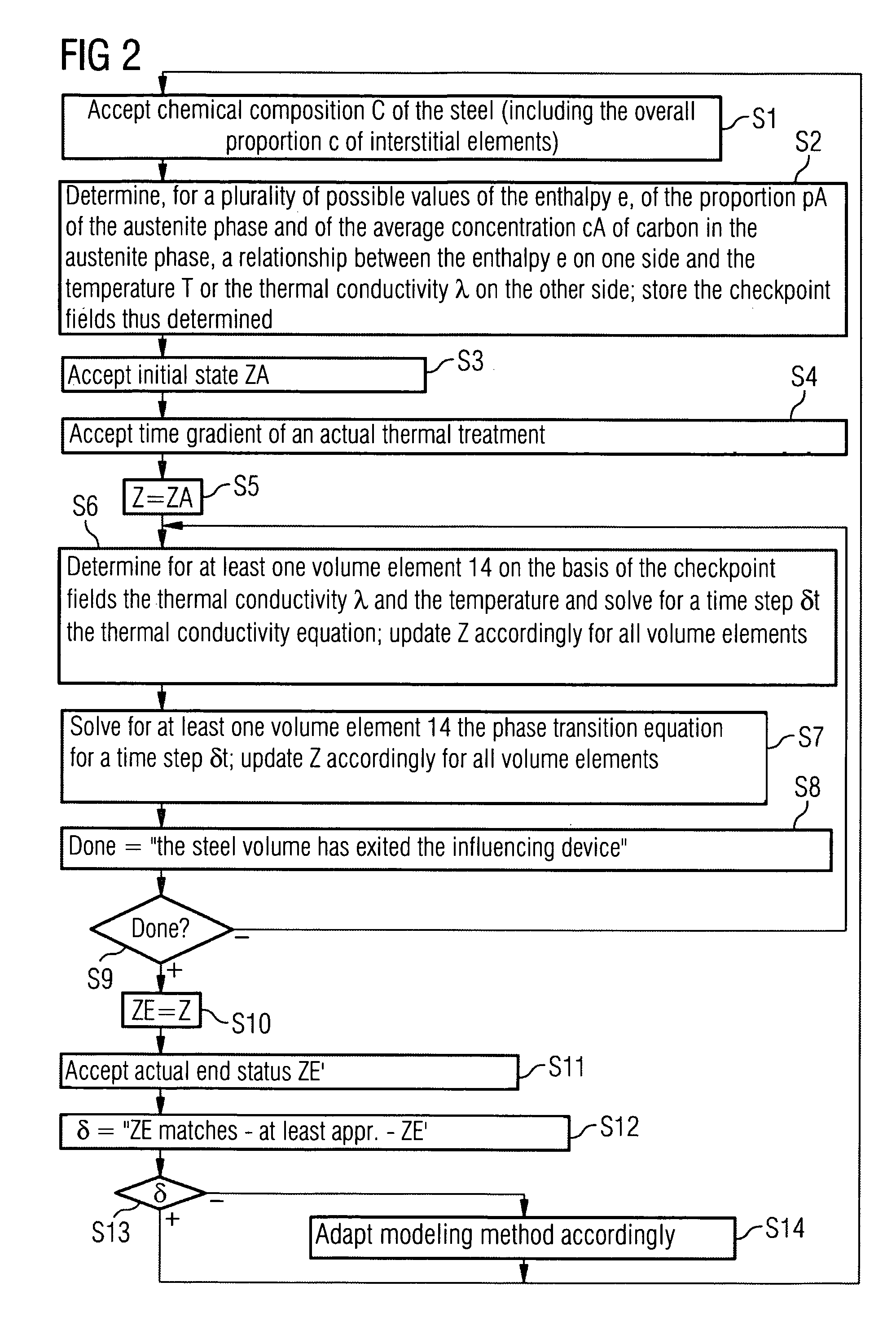

[0056]In accordance with FIG. 1 a computer 1 has the usual components 2 to 8. These are firstly a processor unit 2 and a mass storage device 3. The mass storage device 3 can for example be embodied as a hard disk. There are also interfaces 4 and 5. Interface 4 is an interface for connecting to the computer 1 a data medium 9 embodied as a removable medium. Depending on the embodiment of the interface 4 the data medium 9 can be embodied for example as a CD-ROM or as a USB memory stick. Interface 5 is an interface to a computer network 10, e.g. to the Internet or World Wide Web. The further components 6 to 8 of the computer 1 are an input device 6, an output device 7 and random access memory 8. The input device 6 can for example be a keyboard and a mouse. The output device 7 can be a terminal and a printer.

[0057]A computer program 11 is stored on the removable medium 9. After the removable medium 9 is connected to the interface 4 of the computer 1, the computer program 11 is read out T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| enthalpy | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com