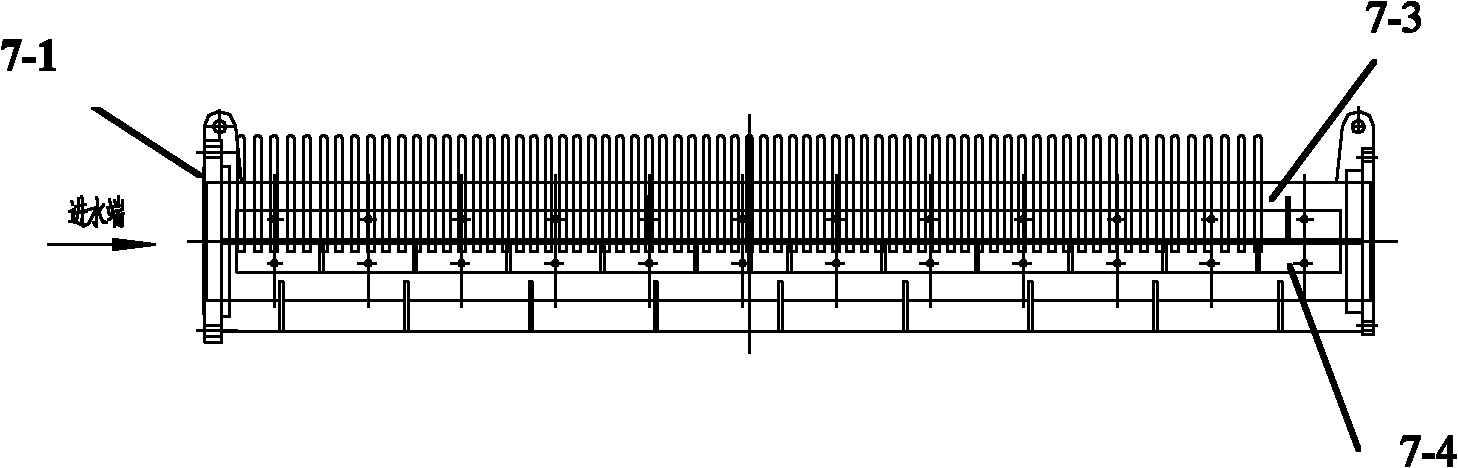

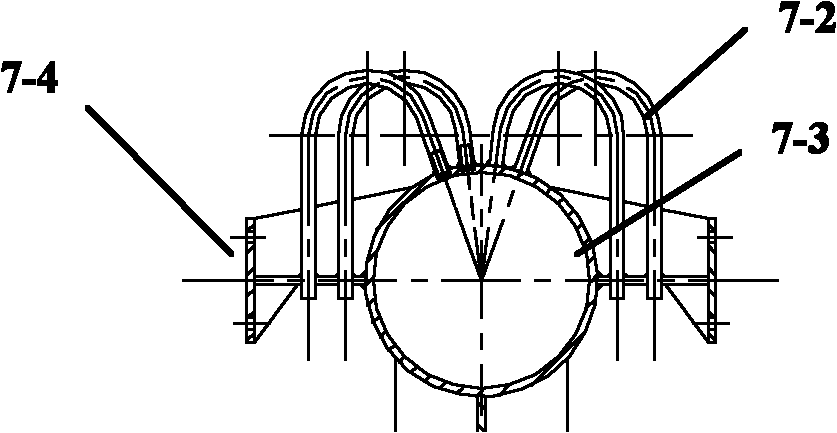

Direct quenching device for medium plate and quenching process thereof

A thick steel plate, direct technology, applied in the direction of quenching device, manufacturing tools, heat treatment equipment, etc., can solve the problem that the cooling capacity of laminar flow cooling device is difficult to realize online quenching of steel plate, the cost of alloying and production process increases, and the water volume cannot be adjusted freely and other problems, to achieve the effect of improving cooling heat transfer effect, large final cooling temperature adjustment range, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Steel type: Q550D

[0051] Rolling process: slab thickness: 150mm, final rolling temperature in the first stage: >1000°C, intermediate billet thickness: 60mm, starting rolling temperature in the second stage: 920°C, final rolling temperature: 800°C, finished product thickness: 20mm.

[0052] Direct quenching process: After the steel plate with a thickness of 20mm exits the finishing mill, the control computer billet is sent into the cooling control area according to the predetermined speed, the number of cooler groups is opened to 10 groups, and the flow rate of the upper cooler is set to 320m 3 / h, the roller speed is 1.5m / s, the cooling speed is 22°C / s, and the final cooling temperature is 400°C. Make full use of the side spray device to clean the hot water on the surface of the steel plate to improve the cooling effect. Use the purging device to limit the cooling area. Prevent the uneven cooling of the steel plate by residual water on the surface of the steel plate, ...

Embodiment 2

[0056] Steel type: Q690D

[0057] Rolling process: slab thickness: 250mm, final rolling temperature in the first stage: >1000°C, intermediate billet thickness: 90mm, starting rolling temperature in the second stage: 940°C, final rolling temperature: 850°C, finished product thickness: 30mm.

[0058] Direct quenching process: After the steel plate with a thickness of 30mm exits the finishing mill, the control computer sends the billet into the cooling control area at a predetermined speed, the number of cooler groups is 13, and the flow rate of the upper cooler is 320m 3 / h, roller table speed 1.5m / s, cooling speed 20°C / s, final cooling temperature 420°C, make full use of the side spray device to clean the hot water on the surface of the steel plate to improve the cooling effect, use the purging device to limit the cooling area, Prevent the uneven cooling of the steel plate by residual water on the surface of the steel plate, and control the cooling plate shape of the steel plat...

example 3

[0062] Steel type: Q800

[0063] Rolling process: slab thickness: 250mm, final rolling temperature in the first stage: >1000°C, intermediate billet thickness: 75mm, starting rolling temperature in the second stage: 900°C, final rolling temperature: 780°C, finished product thickness: 25mm.

[0064] Direct quenching process: After the steel plate with a thickness of 25mm exits the finishing mill, the control computer sends the steel plate into the cooling control area at a predetermined speed, the number of cooler groups is 15, and the flow rate of the upper cooler is 320m 3 / h, roller table speed 1.3m / s, cooling speed 20°C / s, final cooling temperature 400°C, make full use of the side spray device to clean the hot water on the surface of the steel plate to improve the cooling effect, use the purging device to limit the cooling area, Prevent the uneven cooling of the steel plate by residual water on the surface of the steel plate, and control the cooling plate shape of the steel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com