Styrene-acrylate emulsion with hydrophobic oleophylic fluorine-silicon-modified nuclear shell structure and preparation method thereof

A technology of fluorine-silicon modification and core-shell structure, applied in separation methods, chemical instruments and methods, liquid separation, etc., to achieve excellent performance, good hydrophobic and lipophilic effects, and easy-to-control preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

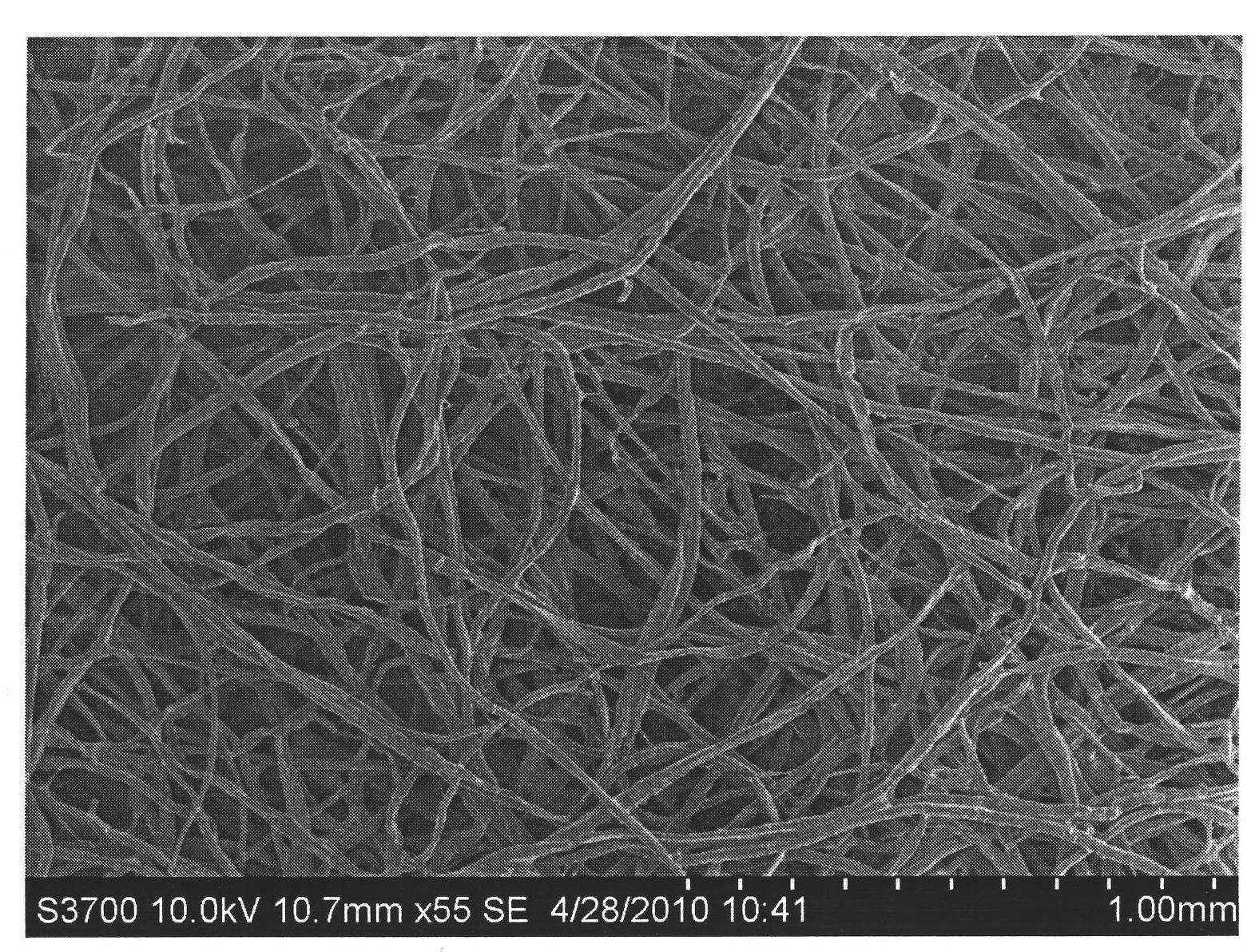

Image

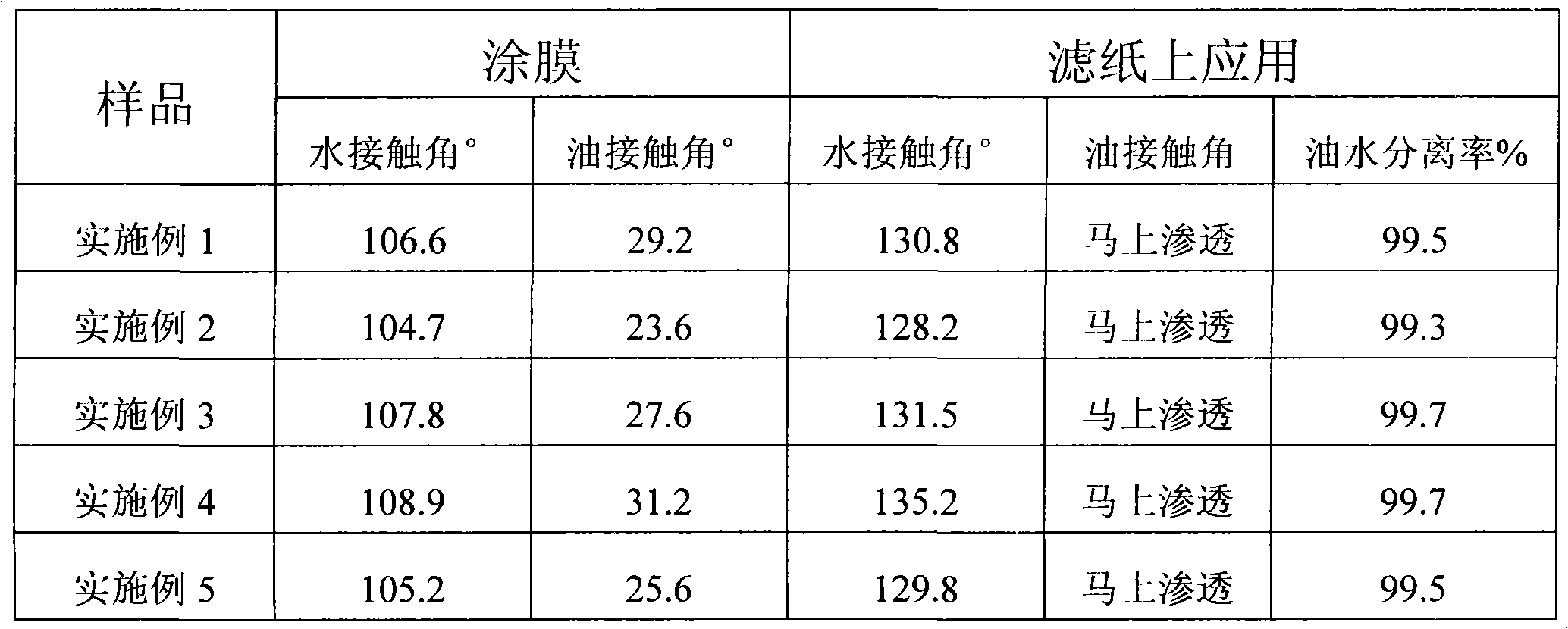

Examples

Embodiment 1

[0031] The first step of allyloxy nonylphenol polyoxyethylene (10) ether ammonium sulfate is an emulsifier; in parts by weight, get 0.1 part of sodium bicarbonate, 80 parts of water and 1.2 parts of emulsifier, join the stirring In the reactor of device, condensing pipe and water bath; heat up to 55°C;

[0032] In the second step, 0.7 parts of potassium persulfate are dissolved in 20 g of water to form an initiator solution, and 16 parts of styrene, 2 parts of methyl methacrylate, 10 parts of butyl acrylate, 0.5 parts of methacrylic acid, and 0.4 parts of N-hydroxy Methacrylamide, 0.05 parts of dodecyl mercaptan, 10 parts of water and 0.2 parts of emulsifier, emulsified at room temperature for 15 minutes, to obtain a pre-emulsion of the core layer mixed monomer;

[0033] In the third step, take 5% by weight of the core layer and mix the pre-emulsion and 5% by weight of the initiator solution, directly add it to the reaction vessel described in the first step, and then heat up ...

Embodiment 2

[0038] In the first step, 0.8 parts of alkyl diphenyl oxide ammonium disulfonate and 0.4 parts of octylphenol polyoxyethylene ether NP-9 are composite emulsifiers; in parts by weight, 0.2 parts of sodium bicarbonate and 120 parts of water And 40wt% composite emulsifier, join in the reactor that stirrer, condensation pipe and water bath are housed; Be warming up to 50 ℃;

[0039] The second step takes 1.2 parts of ammonium persulfate and dissolves 25g in water to form an initiator solution. Take 28 parts of styrene, 4.5 parts of butyl methacrylate, 3 parts of butyl acrylate, 2 parts of acrylic acid, 3 parts of acrylamide, 2.5 parts of Ethylene glycol dimethacrylate, 15 parts of water and 40wt% emulsifier were emulsified at room temperature for 30 minutes to obtain a pre-emulsion of the mixed monomers of the core layer;

[0040] The third step is to take 20wt% core layer pre-emulsion and 30wt% initiator solution, directly add to the reaction vessel described in the first step, a...

Embodiment 3

[0045] The first step is taken in parts by weight, 1.2 parts of sodium dodecylbenzenesulfonate and 0.8 parts of octylphenol polyoxyethylene ether OP-30 are composite emulsifiers; get 0.5 parts of dipotassium hydrogen phosphate, 150 parts of water and The emulsifying agent of 45wt% joins in the reactor that stirrer, condensation pipe and water bath are housed; Warming up to 40 ℃;

[0046] In the second step, 1 part of hydrogen peroxide-ferrous chloride (mass ratio 1: 1) was dissolved in 30 g of water to form an initiator solution, 50 parts of styrene, 14.2 parts of butyl methacrylate, 9 parts of propylene acrylate Ester, 2.8 parts of acrylic acid, 2.2 parts of trihydroxypropylene trimethacrylate, 1.8 parts of N-methylolacrylamide, 30 parts of water and 20wt% emulsifier, emulsified at room temperature for 35min, to obtain a pre-emulsion of the core layer mixed monomer;

[0047] The third step is to take 20wt% nuclear layer mixed monomer pre-emulsion and 25wt% initiator solution,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com