Method for preparing VO2 composite film with optical limiting performance

A composite thin film and optical limiting technology, which is applied in the coating of superimposed layers, the device for coating liquid on the surface, ion implantation plating, etc., can solve the problems of increasing the difficulty of material compounding and the lack of reports on optical limiting films. , to achieve convenient large-area preparation and mass production, improve laser protection performance, and the effect of simple and controllable preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Using the metal vanadium target as the sputtering source, a 200nm thick metal V film was sputtered on a clean quartz substrate under argon gas conditions, the substrate temperature was kept at 200°C, the sputtering time was 60min, and the sputtering power was 150W ;

[0026] 2) Place the substrate sputtered with the V film in a tube furnace, and anneal it with a nitrogen-oxygen mixture, in which the ratio of nitrogen to oxygen is 10:1, the annealing temperature is 480°C, the annealing time is 60min, and cooled to Take out after room temperature;

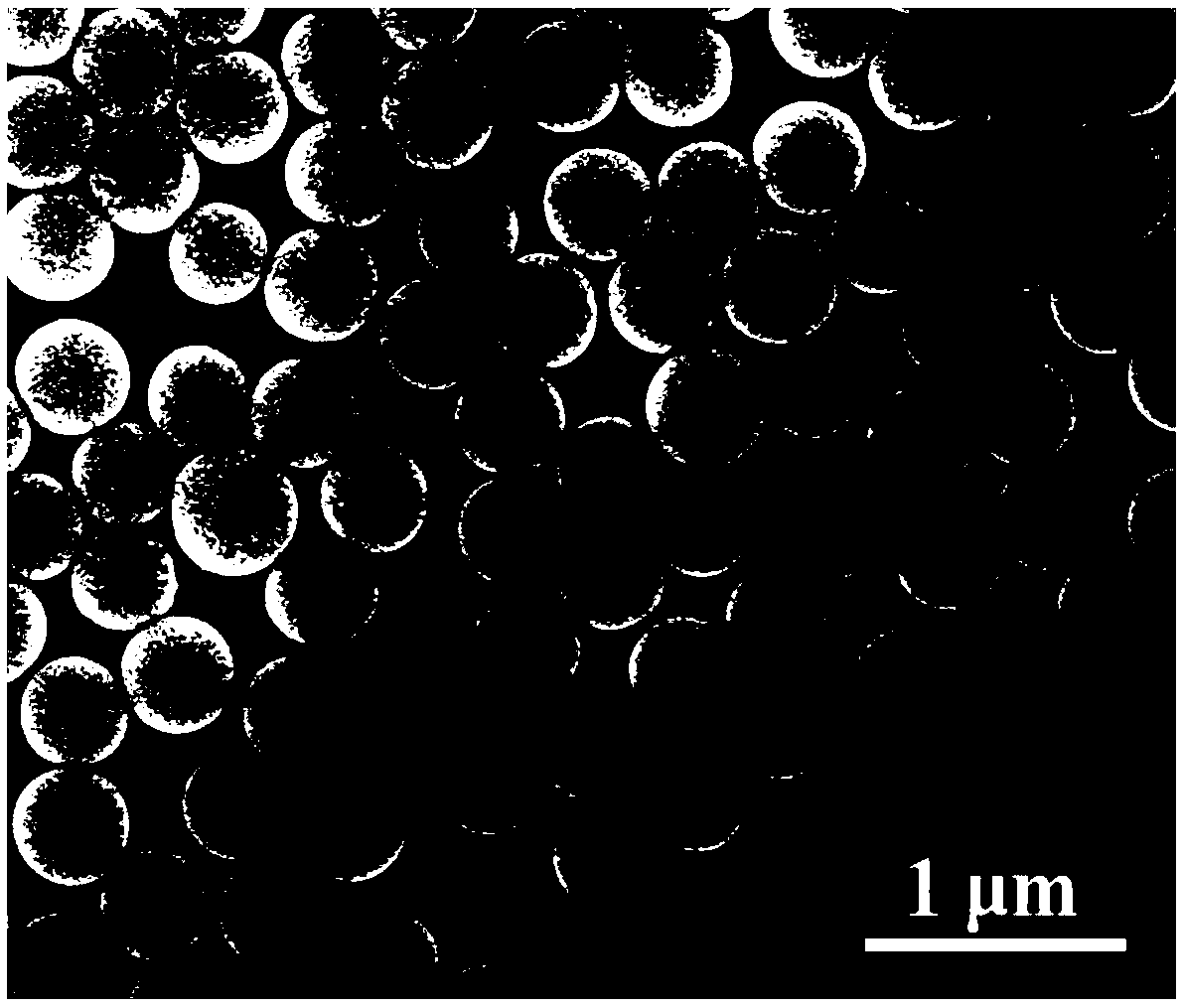

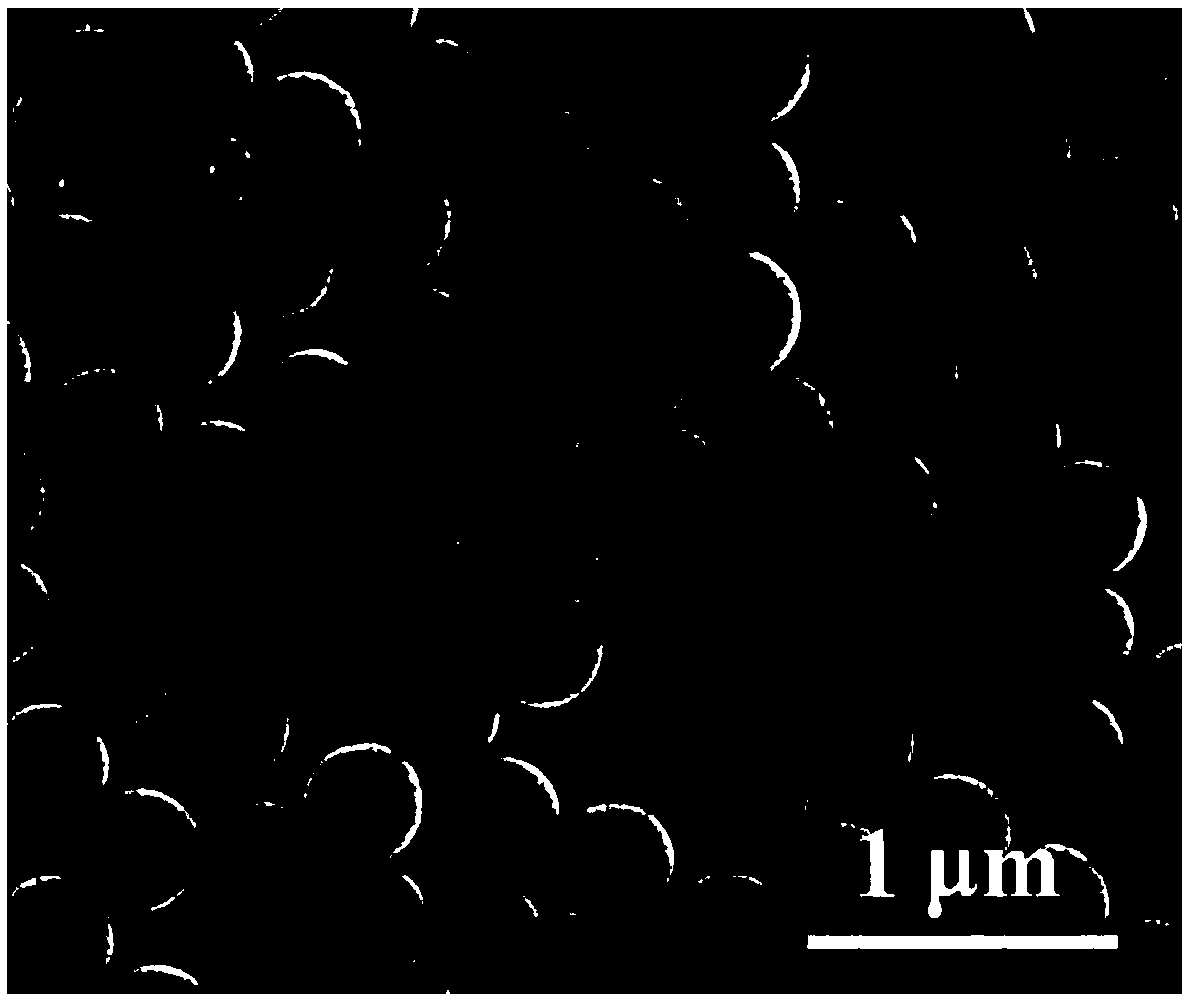

[0027] 3) Mix 50ml of absolute ethanol, 7ml of deionized water, and 7ml of concentrated ammonia water, and stir evenly to obtain a reaction solution; in a constant temperature water bath at 40°C, slowly add 5ml of tetraethyl orthosilicate to the above solution, and stir for 30 minutes. Reaction 24h. After the reaction is completed, centrifuge repeatedly with absolute ethanol, wash, and then disperse by ultrasonic to obtai...

Embodiment 2

[0033] 1) Using the metal vanadium target as the sputtering source, a 200nm thick metal V film was sputtered on a clean quartz substrate under argon gas conditions, the substrate temperature was kept at 200°C, the sputtering time was 60min, and the sputtering power was 150W ;

[0034] 2) Place the substrate sputtered with the V film in a tube furnace, and anneal it with a nitrogen-oxygen mixture, in which the ratio of nitrogen to oxygen is 10:1, the annealing temperature is 480°C, the annealing time is 60min, and cooled to Take out after room temperature;

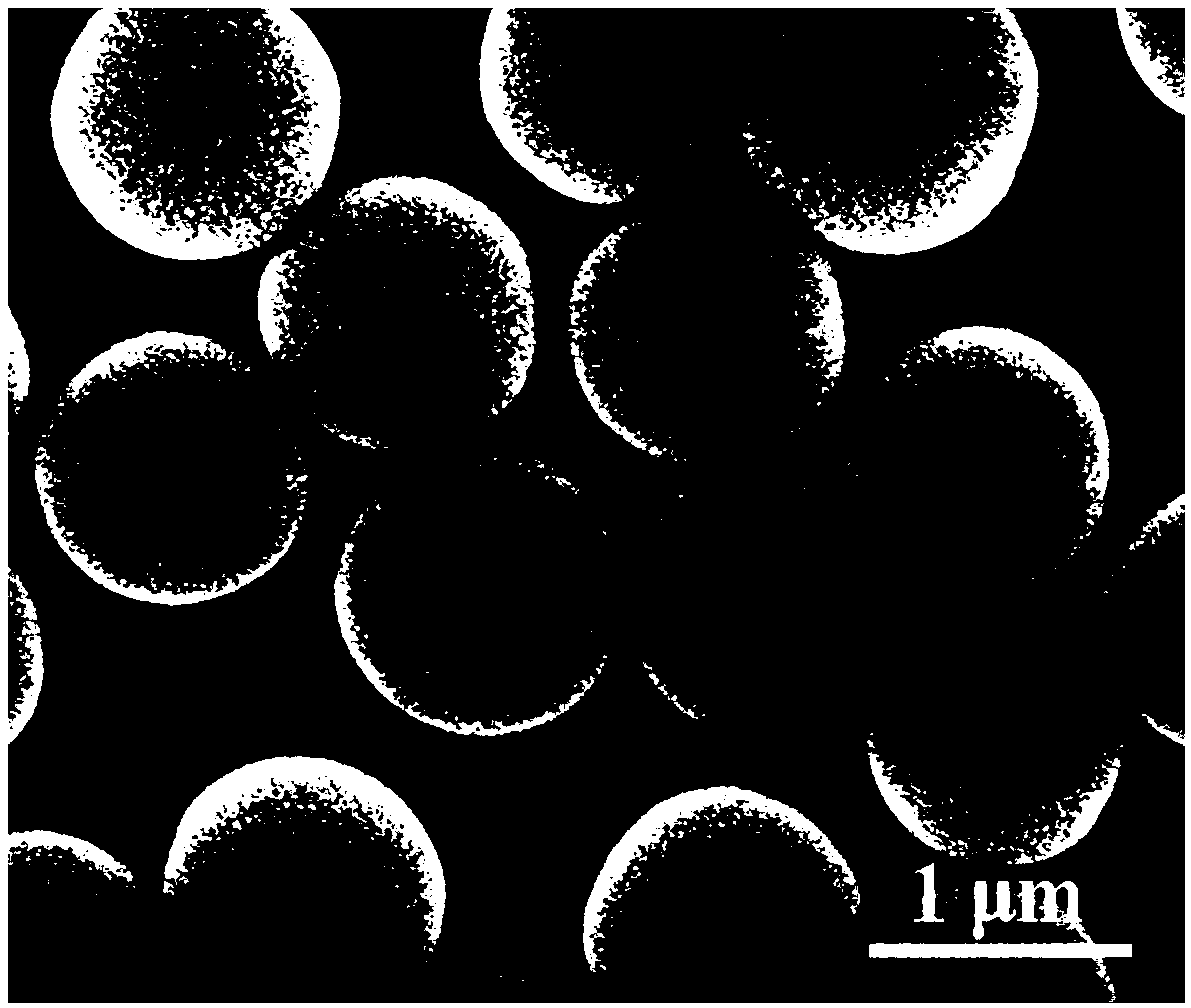

[0035] 3) Mix 50ml of absolute ethanol, 7ml of deionized water, and 7ml of concentrated ammonia water, and stir evenly to obtain a reaction solution; in a constant temperature water bath at 40°C, slowly add 20ml of tetraethyl orthosilicate to the above solution, and stir for 30 minutes. Reaction 24h. After the reaction is completed, centrifuge repeatedly with absolute ethanol, wash, and then disperse by ultrasonic to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com