An ag/vo with laser protection properties 2 Preparation method of composite film

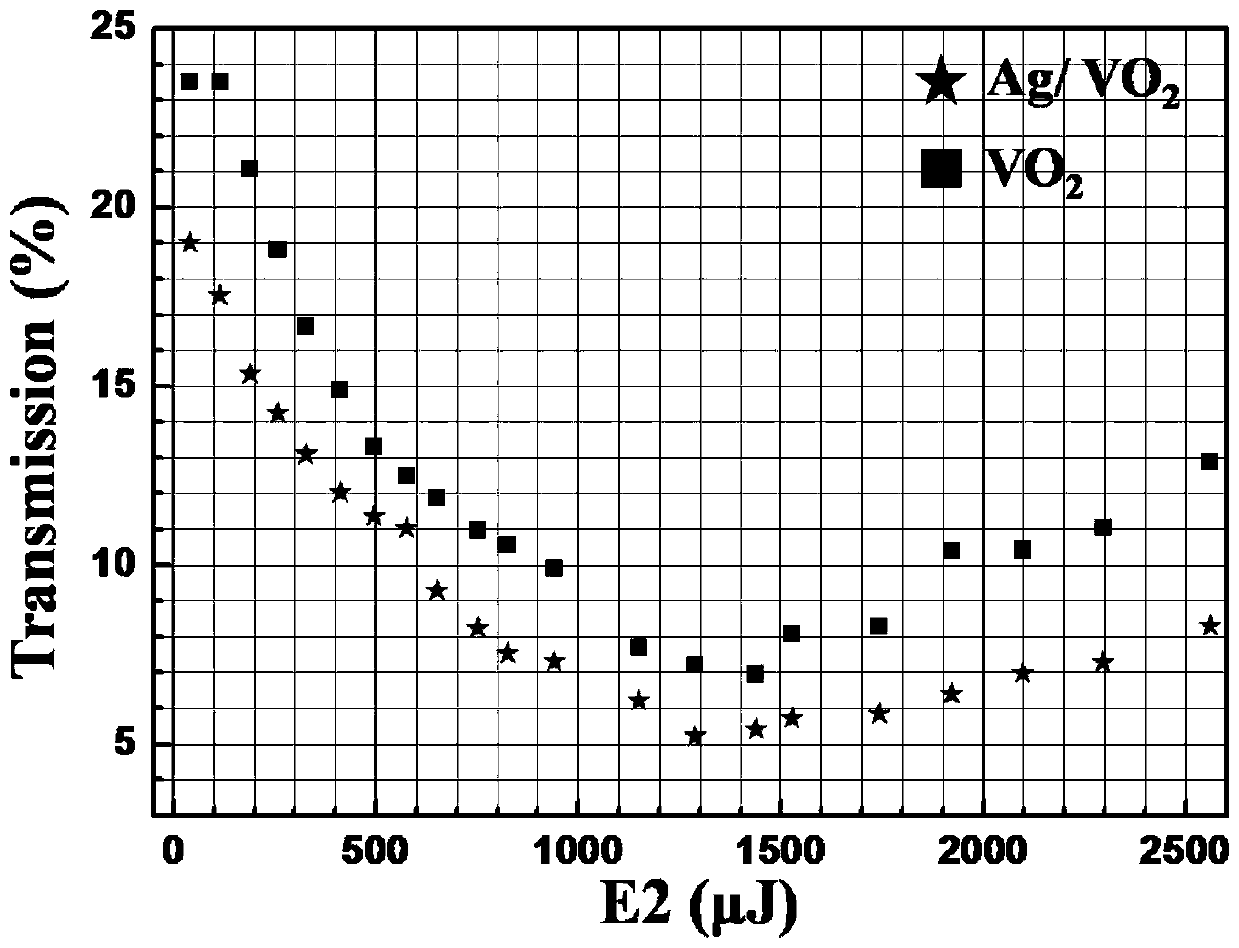

A composite thin film and laser protection technology, which is applied in the direction of superimposed layer plating, liquid chemical plating, vacuum evaporation plating, etc., can solve the problem of weakening the surface plasmon resonance effect of silver nanostructure, the thickness and shape of silver nanostructure layer It is difficult to choose, it is difficult to improve the laser damage threshold of the film, etc., to reduce the laser transmittance, shorten the phase change response time, and improve the laser protection performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Using a metal vanadium target as a sputtering source, a 100nm thick metal vanadium film was sputtered on a clean quartz substrate under argon gas, and the substrate temperature was kept at 200°C;

[0026] 2) Raise the temperature of the tube annealing furnace with one end open, keep it warm at 500°C, and feed nitrogen from the non-open end of the furnace tube, and keep the nitrogen flow at 2L / min;

[0027] 3) Put the prepared metal vanadium film into a quartz crucible, and then push the crucible into the above-mentioned tubular annealing furnace for annealing. The annealing time is 10 minutes, and then pull out the crucible for rapid air cooling. get the desired VO 2 film.

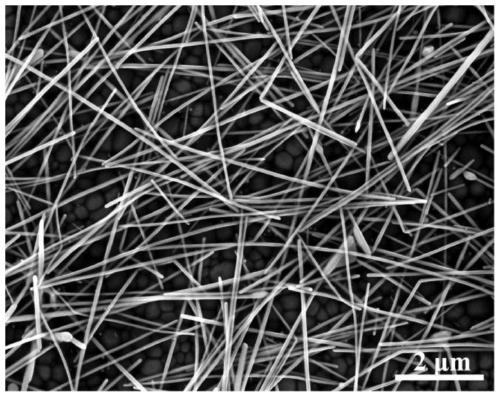

[0028] 4) with AgNO 3 is the silver source, ethylene glycol is the reducing agent, polyvinylpyrrolidone is the stabilizer and dispersant, and HCl is the nucleation control agent. The silver nanowires are obtained by chemical reduction reaction, and the product is centrifuged and dispersed into ...

Embodiment 2

[0033] 1) Using a metal vanadium target as a sputtering source, a 100nm thick metal vanadium film was sputtered on a clean quartz substrate under argon gas, and the substrate temperature was kept at 200°C;

[0034] 2) Raise the temperature of the tube annealing furnace with one end open, keep it warm at 500°C, and feed nitrogen from the non-open end of the furnace tube, and keep the nitrogen flow at 2L / min;

[0035] 3) Put the prepared metal vanadium film into a quartz crucible, and then push the crucible into the above-mentioned tubular annealing furnace for annealing. The annealing time is 10 minutes, and then pull out the crucible for rapid air cooling. get the desired VO 2 film.

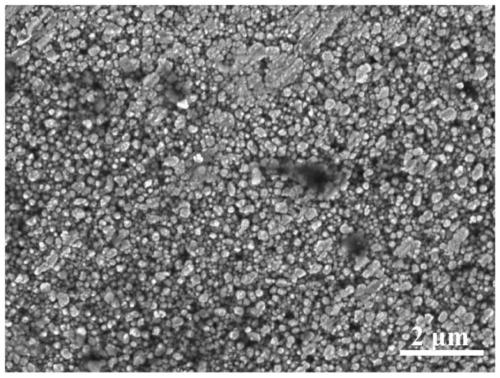

[0036] 4) with AgNO 3 Silver source, ethylene glycol as reducing agent, polyvinylpyrrolidone as stabilizer and dispersant, use chemical reduction reaction to obtain silver nanoparticles, centrifuge the product and disperse it in ethanol to obtain a silver nanoparticle dispersion with a concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com